What is Global Compact Vacuum Arc Melting Furnace Market?

The Global Compact Vacuum Arc Melting Furnace Market is a specialized segment within the broader industrial furnace industry, focusing on the production and refinement of metals through vacuum arc melting technology. This type of furnace is designed to melt metals in a vacuum environment, which helps in reducing contamination and achieving high-purity metal products. The compact design of these furnaces makes them suitable for smaller-scale operations or laboratories where space is a constraint. They are particularly useful in industries that require precise control over the melting process, such as aerospace, electronics, and advanced materials manufacturing. The market for these furnaces is driven by the increasing demand for high-quality metal alloys and the need for efficient and environmentally friendly melting processes. As industries continue to innovate and develop new materials, the demand for compact vacuum arc melting furnaces is expected to grow, providing opportunities for manufacturers to expand their product offerings and improve technological capabilities. The market is characterized by a mix of established players and new entrants, each striving to offer more efficient, reliable, and cost-effective solutions to meet the evolving needs of their customers.

Less than 10t, 10-20t in the Global Compact Vacuum Arc Melting Furnace Market:

In the Global Compact Vacuum Arc Melting Furnace Market, the categorization based on capacity, such as Less than 10t and 10-20t, plays a crucial role in addressing the diverse needs of various industries. Furnaces with a capacity of less than 10 tons are typically used in applications where smaller batches of high-purity metals are required. These smaller furnaces are ideal for research and development purposes, as well as for specialized manufacturing processes that demand precision and control. They are often employed in sectors like electronics, where the production of small quantities of high-quality metal is essential. The compact size and lower capacity make them more energy-efficient and easier to manage, which is particularly beneficial for companies looking to minimize operational costs while maintaining high standards of quality. On the other hand, furnaces with a capacity of 10-20 tons are designed to handle larger volumes of metal, making them suitable for medium-scale industrial applications. These furnaces are often used in industries such as aerospace and automotive, where the demand for high-performance metal alloys is significant. The ability to process larger quantities of metal in a single batch allows manufacturers to increase their production efficiency and meet the growing demands of their customers. Additionally, the larger capacity furnaces are equipped with advanced features that enable precise control over the melting process, ensuring that the final product meets the stringent quality standards required by these industries. The choice between less than 10t and 10-20t furnaces depends largely on the specific requirements of the application and the scale of production. Companies that require flexibility and the ability to quickly adapt to changing production needs may opt for smaller furnaces, while those with a steady demand for larger quantities of metal may find the larger capacity furnaces more suitable. Regardless of the capacity, both types of furnaces offer the benefits of vacuum arc melting technology, including reduced contamination, improved metal purity, and enhanced control over the melting process. As the market for compact vacuum arc melting furnaces continues to evolve, manufacturers are focusing on developing innovative solutions that cater to the diverse needs of their customers. This includes the integration of advanced technologies such as automation and digital monitoring systems, which enhance the efficiency and reliability of the melting process. By offering a range of furnace capacities and features, manufacturers can better serve the needs of different industries and capitalize on the growing demand for high-quality metal products. The ongoing advancements in furnace technology are expected to drive further growth in the market, providing opportunities for companies to expand their product offerings and strengthen their competitive position.

Metal Smelting, Ore Smelting, Others in the Global Compact Vacuum Arc Melting Furnace Market:

The Global Compact Vacuum Arc Melting Furnace Market finds its application in various areas, including metal smelting, ore smelting, and other specialized processes. In metal smelting, these furnaces are used to melt and refine metals to produce high-purity alloys. The vacuum environment minimizes the presence of impurities and gases, resulting in superior quality metal products. This is particularly important in industries such as aerospace and electronics, where the performance and reliability of metal components are critical. The ability to produce high-purity metals with precise control over the melting process makes compact vacuum arc melting furnaces an essential tool for manufacturers looking to meet the stringent quality standards of these industries. In ore smelting, compact vacuum arc melting furnaces are used to extract metals from their ores. The vacuum environment helps in reducing the oxidation of metals during the smelting process, leading to higher yields and improved metal quality. This is especially beneficial for the production of rare and precious metals, where maximizing yield and purity is of utmost importance. The compact design of these furnaces allows for efficient processing of smaller batches of ore, making them suitable for operations where space and resources are limited. The ability to achieve high-purity metal extraction with minimal environmental impact is a key advantage of using vacuum arc melting technology in ore smelting applications. Beyond metal and ore smelting, compact vacuum arc melting furnaces are also used in other specialized processes that require precise control over the melting environment. This includes the production of advanced materials and alloys used in cutting-edge technologies such as semiconductors, superconductors, and high-performance coatings. The ability to tailor the melting process to specific material requirements allows manufacturers to develop innovative products that meet the demands of emerging industries. The versatility of compact vacuum arc melting furnaces makes them a valuable asset for companies looking to explore new applications and expand their product offerings. Overall, the usage of compact vacuum arc melting furnaces in metal smelting, ore smelting, and other specialized processes highlights their importance in the production of high-quality metal products. The ability to achieve superior metal purity, reduce contamination, and enhance process control makes these furnaces an indispensable tool for manufacturers across various industries. As the demand for high-performance materials continues to grow, the role of compact vacuum arc melting furnaces in meeting these needs is expected to become increasingly significant. The ongoing advancements in furnace technology and the development of new applications are likely to drive further growth in the market, providing opportunities for companies to innovate and expand their capabilities.

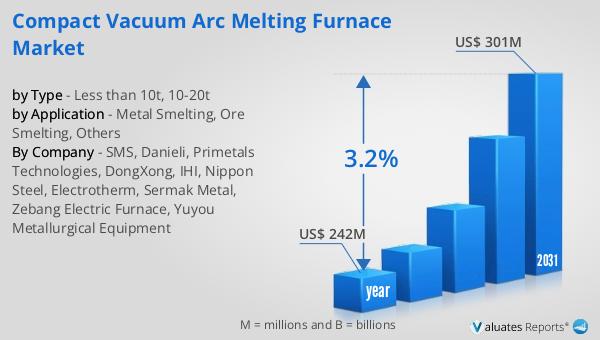

Global Compact Vacuum Arc Melting Furnace Market Outlook:

The global market for Compact Vacuum Arc Melting Furnace was valued at $242 million in 2024, with projections indicating a growth to $301 million by 2031. This represents a compound annual growth rate (CAGR) of 3.2% over the forecast period. The steady growth of this market can be attributed to the increasing demand for high-quality metal products across various industries. As manufacturers seek to improve the efficiency and quality of their production processes, the adoption of compact vacuum arc melting furnaces is expected to rise. These furnaces offer significant advantages in terms of metal purity, process control, and environmental impact, making them an attractive option for companies looking to enhance their competitive edge. The market outlook suggests that the demand for compact vacuum arc melting furnaces will continue to grow as industries such as aerospace, electronics, and advanced materials manufacturing expand. The ability to produce high-purity metals with minimal contamination is a key factor driving the adoption of these furnaces. Additionally, the compact design and energy efficiency of these furnaces make them suitable for a wide range of applications, from small-scale research and development to medium-scale industrial production. As companies continue to innovate and develop new materials, the need for efficient and reliable melting solutions is expected to increase, further fueling the growth of the market. Manufacturers in the compact vacuum arc melting furnace market are focusing on developing advanced technologies and features to meet the evolving needs of their customers. This includes the integration of automation and digital monitoring systems, which enhance the efficiency and reliability of the melting process. By offering a range of furnace capacities and features, manufacturers can better serve the diverse needs of different industries and capitalize on the growing demand for high-quality metal products. The ongoing advancements in furnace technology are expected to drive further growth in the market, providing opportunities for companies to expand their product offerings and strengthen their competitive position.

| Report Metric | Details |

| Report Name | Compact Vacuum Arc Melting Furnace Market |

| Accounted market size in year | US$ 242 million |

| Forecasted market size in 2031 | US$ 301 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SMS, Danieli, Primetals Technologies, DongXong, IHI, Nippon Steel, Electrotherm, Sermak Metal, Zebang Electric Furnace, Yuyou Metallurgical Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |