What is Global Aluminum Heat Sink Market?

The Global Aluminum Heat Sink Market is a crucial segment within the broader thermal management industry, focusing on the production and distribution of aluminum heat sinks. These components are essential for dissipating heat in various electronic devices and systems, ensuring optimal performance and longevity. Aluminum is favored for its excellent thermal conductivity, lightweight nature, and cost-effectiveness, making it a popular choice for heat sink manufacturing. The market encompasses a wide range of applications, from consumer electronics to industrial machinery, where efficient heat dissipation is critical. As technology advances and devices become more powerful, the demand for effective thermal management solutions like aluminum heat sinks continues to grow. This market is characterized by continuous innovation, with manufacturers striving to enhance the performance and efficiency of their products to meet the evolving needs of various industries. The global reach of this market highlights its significance in supporting technological advancements and maintaining the reliability of electronic systems worldwide.

Passive Heat Sink, Active Heat Sink in the Global Aluminum Heat Sink Market:

In the realm of the Global Aluminum Heat Sink Market, heat sinks are categorized into two primary types: passive and active. Passive heat sinks rely on natural convection to dissipate heat. They are typically made of aluminum due to its excellent thermal conductivity and lightweight properties. These heat sinks are designed with fins or other structures that increase the surface area, allowing heat to be transferred from the electronic component to the surrounding air. Passive heat sinks are favored in applications where noise is a concern, as they operate silently without the need for additional components like fans. They are commonly used in devices with lower heat output or where space constraints limit the use of active cooling solutions. On the other hand, active heat sinks incorporate additional components, such as fans or blowers, to enhance heat dissipation. The inclusion of these components allows for more efficient cooling, making active heat sinks suitable for high-performance applications where significant heat is generated. The fans or blowers increase airflow over the heat sink, improving the rate of heat transfer from the component to the environment. Active heat sinks are often used in high-power electronic devices, such as gaming consoles, high-performance computers, and industrial equipment, where maintaining optimal operating temperatures is critical. The choice between passive and active heat sinks in the Global Aluminum Heat Sink Market depends on several factors, including the specific thermal management requirements of the application, space constraints, noise considerations, and cost. Manufacturers in this market are continually innovating to improve the efficiency and performance of both passive and active heat sinks, addressing the diverse needs of various industries. As technology continues to advance, the demand for effective thermal management solutions is expected to grow, driving further developments in the design and functionality of aluminum heat sinks.

Automobile, Electronic, Others in the Global Aluminum Heat Sink Market:

The Global Aluminum Heat Sink Market finds extensive usage across various sectors, including the automobile, electronic, and other industries. In the automobile industry, aluminum heat sinks are crucial for managing the heat generated by various components, such as power electronics, LED lighting systems, and infotainment systems. As vehicles become more technologically advanced, with features like electric drivetrains and advanced driver-assistance systems, the need for efficient thermal management solutions becomes increasingly important. Aluminum heat sinks help ensure the reliability and performance of these components, contributing to the overall efficiency and safety of modern vehicles. In the electronics industry, aluminum heat sinks are widely used to dissipate heat from components such as CPUs, GPUs, and power transistors. As electronic devices become more powerful and compact, the challenge of managing heat effectively becomes more pronounced. Aluminum heat sinks play a vital role in maintaining the performance and longevity of these devices by preventing overheating and ensuring stable operation. Beyond the automobile and electronics industries, aluminum heat sinks are also used in various other applications, such as industrial machinery, telecommunications equipment, and renewable energy systems. In industrial settings, heat sinks are essential for managing the heat generated by heavy machinery and equipment, ensuring their efficient and reliable operation. In telecommunications, aluminum heat sinks help manage the heat produced by network equipment, supporting the performance and reliability of communication systems. In renewable energy systems, such as solar inverters and wind turbines, aluminum heat sinks are used to dissipate heat from power electronics, contributing to the efficiency and longevity of these systems. The versatility and effectiveness of aluminum heat sinks make them an indispensable component in a wide range of applications, highlighting their importance in the Global Aluminum Heat Sink Market.

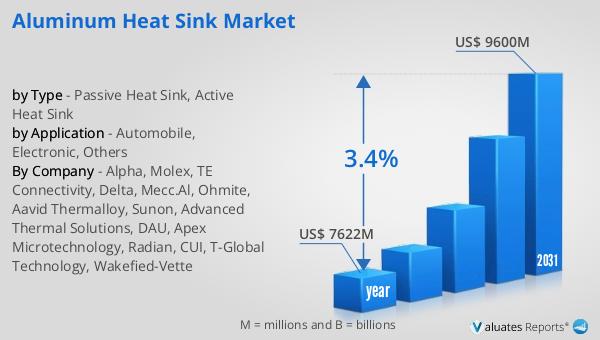

Global Aluminum Heat Sink Market Outlook:

The global market for aluminum heat sinks was valued at approximately $7,622 million in 2024. This market is projected to grow steadily, reaching an estimated size of $9,600 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.4% over the forecast period. The steady increase in market size reflects the growing demand for efficient thermal management solutions across various industries. As electronic devices become more powerful and compact, the need for effective heat dissipation becomes increasingly critical. Aluminum heat sinks, with their excellent thermal conductivity and lightweight properties, are well-suited to meet this demand. The market's growth is also driven by advancements in technology and the increasing adoption of electronic devices in various sectors, including automotive, consumer electronics, and industrial applications. Manufacturers in the Global Aluminum Heat Sink Market are continually innovating to enhance the performance and efficiency of their products, addressing the evolving needs of their customers. This ongoing innovation, coupled with the growing demand for thermal management solutions, is expected to drive the market's growth in the coming years. The projected growth of the Global Aluminum Heat Sink Market underscores the importance of these components in supporting technological advancements and ensuring the reliability of electronic systems worldwide.

| Report Metric | Details |

| Report Name | Aluminum Heat Sink Market |

| Accounted market size in year | US$ 7622 million |

| Forecasted market size in 2031 | US$ 9600 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alpha, Molex, TE Connectivity, Delta, Mecc.Al, Ohmite, Aavid Thermalloy, Sunon, Advanced Thermal Solutions, DAU, Apex Microtechnology, Radian, CUI, T-Global Technology, Wakefied-Vette |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |