What is Global Electric Tensioning Machine Market?

The Global Electric Tensioning Machine Market is a specialized segment within the broader machinery and equipment industry, focusing on devices designed to apply precise tension to various materials. These machines are crucial in industries where maintaining consistent tension is vital for product quality and operational efficiency. Electric tensioning machines are used in applications ranging from cable and wire manufacturing to textile production and construction. They offer advantages such as improved accuracy, reduced manual labor, and enhanced safety compared to traditional tensioning methods. The market is driven by technological advancements, increasing automation in manufacturing processes, and the growing demand for high-quality products. As industries continue to evolve, the need for efficient and reliable tensioning solutions is expected to rise, making electric tensioning machines an essential component in modern industrial operations. The market's growth is also supported by the increasing adoption of smart technologies and the integration of IoT in machinery, which enhances the functionality and monitoring capabilities of these machines. Overall, the Global Electric Tensioning Machine Market is poised for steady growth as industries seek to optimize their production processes and improve product quality.

Tractor, Tensioner, All-in-one in the Global Electric Tensioning Machine Market:

In the Global Electric Tensioning Machine Market, various types of machines are utilized to meet the diverse needs of different industries. Among these, the Tractor, Tensioner, and All-in-one machines play significant roles. Tractors in this context are not the agricultural vehicles but rather specialized machines designed to pull and maintain tension on cables or wires during installation or maintenance processes. These machines are essential in industries such as telecommunications and power distribution, where precise tensioning is crucial for the integrity and performance of cables. Tractors are equipped with advanced control systems that allow operators to adjust tension levels accurately, ensuring that cables are installed correctly and safely. Tensioners, on the other hand, are devices specifically designed to apply and maintain tension on a material, such as a cable or wire, during various processes. They are used in applications where maintaining consistent tension is critical to prevent material damage or operational failures. Tensioners are commonly used in industries like construction, where they help ensure that cables and wires are installed with the correct tension to support structural integrity. These machines are often equipped with sensors and feedback systems that provide real-time data on tension levels, allowing operators to make necessary adjustments to maintain optimal performance. The All-in-one machines combine the functionalities of both tractors and tensioners, offering a comprehensive solution for industries that require both pulling and tensioning capabilities. These machines are particularly useful in complex projects where multiple tensioning tasks need to be performed simultaneously. The All-in-one machines are designed to streamline operations, reduce the need for multiple pieces of equipment, and enhance overall efficiency. They are equipped with advanced features such as programmable controls, remote monitoring, and automated tension adjustment, making them ideal for modern industrial applications. The integration of smart technologies in these machines further enhances their capabilities, allowing for improved precision, reduced downtime, and increased productivity. As industries continue to demand more efficient and versatile tensioning solutions, the Tractor, Tensioner, and All-in-one machines are expected to play a crucial role in meeting these needs. Their ability to adapt to various applications and provide reliable performance makes them indispensable tools in the Global Electric Tensioning Machine Market.

Medium and High Voltage Project, Ultra-high Voltage Project, UHV Voltage Project in the Global Electric Tensioning Machine Market:

The Global Electric Tensioning Machine Market finds extensive usage in various high-stakes projects, including Medium and High Voltage Projects, Ultra-high Voltage Projects, and UHV Voltage Projects. In Medium and High Voltage Projects, electric tensioning machines are employed to ensure that cables and wires are installed with the precise tension required to maintain electrical integrity and safety. These projects often involve the installation of power lines and cables over long distances, where maintaining consistent tension is crucial to prevent sagging, breakage, or electrical faults. Electric tensioning machines provide the accuracy and control needed to achieve the desired tension levels, ensuring that the cables can withstand environmental stresses and operational demands. In Ultra-high Voltage Projects, the stakes are even higher, as these projects involve the transmission of electricity at extremely high voltages over vast distances. The use of electric tensioning machines in these projects is critical to ensure that the cables are installed with the exact tension needed to handle the high voltage levels without compromising safety or performance. These machines are equipped with advanced control systems that allow for precise tension adjustments, ensuring that the cables remain stable and secure throughout their operational lifespan. In UHV Voltage Projects, which represent the pinnacle of voltage transmission technology, electric tensioning machines play an indispensable role in maintaining the integrity and reliability of the transmission infrastructure. These projects require the highest levels of precision and control, as any deviation in tension can lead to catastrophic failures or significant power losses. Electric tensioning machines used in UHV projects are designed to provide unparalleled accuracy and reliability, with features such as real-time monitoring, automated tension adjustments, and remote control capabilities. These machines are essential for ensuring that the cables can withstand the immense electrical and mechanical stresses associated with UHV transmission, thereby safeguarding the stability and efficiency of the power grid. Overall, the usage of electric tensioning machines in these high-voltage projects underscores their importance in modern electrical infrastructure development. Their ability to provide precise tension control, enhance safety, and improve operational efficiency makes them a vital component in the successful execution of Medium and High Voltage, Ultra-high Voltage, and UHV Voltage Projects.

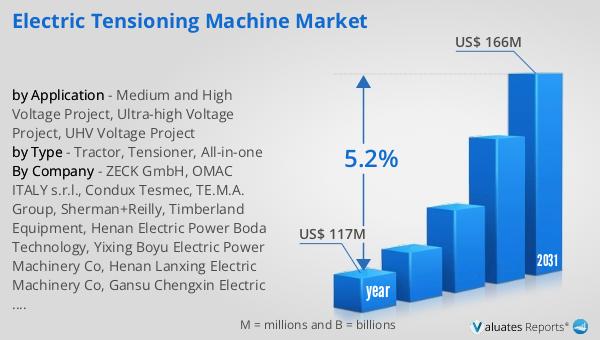

Global Electric Tensioning Machine Market Outlook:

The outlook for the Global Electric Tensioning Machine Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 117 million, reflecting its significance in various industrial applications. By 2031, it is anticipated that the market will expand to a revised size of US$ 166 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.2% over the forecast period. This upward trend highlights the increasing demand for electric tensioning machines across different sectors, driven by the need for precise tension control and enhanced operational efficiency. The market's expansion is supported by technological advancements, such as the integration of smart technologies and IoT capabilities in tensioning machines, which enhance their functionality and monitoring capabilities. Additionally, the growing emphasis on automation and the need for high-quality products in industries like telecommunications, construction, and power distribution contribute to the market's positive outlook. As industries continue to evolve and seek more efficient and reliable tensioning solutions, the Global Electric Tensioning Machine Market is poised to play a crucial role in meeting these demands. The projected growth underscores the importance of these machines in modern industrial operations and their potential to drive innovation and efficiency in various applications.

| Report Metric | Details |

| Report Name | Electric Tensioning Machine Market |

| Accounted market size in year | US$ 117 million |

| Forecasted market size in 2031 | US$ 166 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ZECK GmbH, OMAC ITALY s.r.l., Condux Tesmec, TE.M.A. Group, Sherman+Reilly, Timberland Equipment, Henan Electric Power Boda Technology, Yixing Boyu Electric Power Machinery Co, Henan Lanxing Electric Machinery Co, Gansu Chengxin Electric Power Technology Co, Ningbo Huaxiang Dongfang Machinery & Tools of Power Co |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |