What is Global UHP Electropolished Stainless Steel Tubing Market?

The Global UHP Electropolished Stainless Steel Tubing Market refers to the worldwide industry focused on the production and distribution of ultra-high purity (UHP) electropolished stainless steel tubing. This type of tubing is meticulously manufactured to meet stringent cleanliness and smoothness standards, making it ideal for applications that require the highest levels of purity and corrosion resistance. The electropolishing process involves electrochemical treatment that removes a thin layer of material from the surface, resulting in a microscopically smooth and contaminant-free finish. This market is driven by the increasing demand from industries such as pharmaceuticals, semiconductors, and biotechnology, where contamination control is critical. The tubing is used in systems that transport gases and liquids, ensuring that these substances remain uncontaminated throughout the process. The market's growth is also fueled by advancements in manufacturing technologies and the rising need for high-performance materials in various high-tech applications. As industries continue to prioritize purity and performance, the demand for UHP electropolished stainless steel tubing is expected to grow.

316L, 316L VIM/VAR in the Global UHP Electropolished Stainless Steel Tubing Market:

316L and 316L VIM/VAR are specific grades of stainless steel that are highly relevant in the Global UHP Electropolished Stainless Steel Tubing Market. 316L is a low-carbon version of 316 stainless steel, which contains molybdenum, enhancing its corrosion resistance, especially against chlorides and other industrial solvents. This makes 316L an excellent choice for environments where the tubing will be exposed to harsh chemicals and high temperatures. The low carbon content also minimizes the risk of carbide precipitation during welding, which can lead to intergranular corrosion. On the other hand, 316L VIM/VAR stands for Vacuum Induction Melted/Vacuum Arc Remelted. This process involves melting the steel in a vacuum to remove impurities and then remelting it to ensure a uniform composition and structure. The VIM/VAR process results in a material with superior cleanliness and mechanical properties, making it ideal for ultra-high purity applications. The enhanced purity and structural integrity of 316L VIM/VAR stainless steel make it particularly suitable for critical applications in the semiconductor and pharmaceutical industries, where even the smallest contaminants can cause significant issues. The electropolishing process further enhances the surface finish of these materials, ensuring that they meet the stringent requirements of UHP applications. The combination of 316L's inherent corrosion resistance and the additional benefits of the VIM/VAR process makes these materials highly sought after in the UHP electropolished stainless steel tubing market.

Pharmaceutical, Semiconductor, Others in the Global UHP Electropolished Stainless Steel Tubing Market:

The Global UHP Electropolished Stainless Steel Tubing Market finds extensive usage in various sectors, including pharmaceuticals, semiconductors, and others. In the pharmaceutical industry, the need for contamination-free environments is paramount. UHP electropolished stainless steel tubing is used in the production and transportation of pharmaceutical products to ensure that there are no impurities that could compromise the quality and safety of the drugs. The smooth, polished surface of the tubing prevents the buildup of contaminants and facilitates easy cleaning and sterilization, which are critical in maintaining the purity of pharmaceutical products. In the semiconductor industry, the demand for ultra-high purity materials is even more stringent. The manufacturing of semiconductors involves processes that are highly sensitive to contamination. UHP electropolished stainless steel tubing is used to transport ultra-pure gases and chemicals required in the fabrication of semiconductor devices. The tubing's electropolished surface ensures that there are no microscopic imperfections where contaminants could accumulate, thus maintaining the integrity of the semiconductor manufacturing process. Other industries that benefit from UHP electropolished stainless steel tubing include biotechnology, food and beverage, and aerospace. In biotechnology, the tubing is used in the production of biologics and other sensitive products where purity is crucial. In the food and beverage industry, the tubing ensures that products are free from contaminants, maintaining their quality and safety. In aerospace, the tubing is used in systems that require high performance and reliability under extreme conditions. The versatility and superior performance of UHP electropolished stainless steel tubing make it an essential component in these high-tech industries.

Global UHP Electropolished Stainless Steel Tubing Market Outlook:

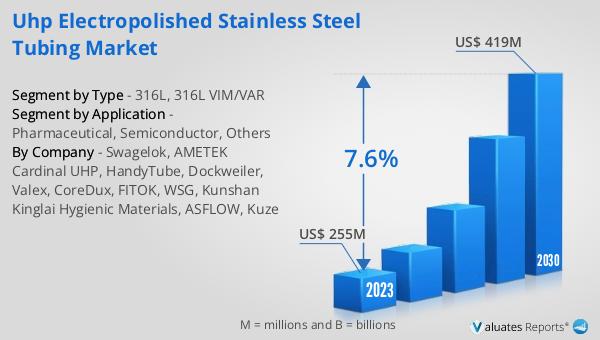

The global UHP Electropolished Stainless Steel Tubing market was valued at US$ 255 million in 2023 and is anticipated to reach US$ 419 million by 2030, witnessing a CAGR of 7.6% during the forecast period 2024-2030. This market outlook indicates a robust growth trajectory driven by the increasing demand for ultra-high purity materials across various industries. The pharmaceutical and semiconductor sectors, in particular, are expected to be significant contributors to this growth due to their stringent requirements for contamination control and high-performance materials. The rising adoption of advanced manufacturing technologies and the growing emphasis on quality and purity in production processes are also key factors propelling the market forward. As industries continue to evolve and prioritize the use of high-purity materials, the demand for UHP electropolished stainless steel tubing is likely to see sustained growth. This positive market outlook underscores the importance of UHP electropolished stainless steel tubing in ensuring the integrity and performance of critical applications across diverse sectors.

| Report Metric | Details |

| Report Name | UHP Electropolished Stainless Steel Tubing Market |

| Accounted market size in 2023 | US$ 255 million |

| Forecasted market size in 2030 | US$ 419 million |

| CAGR | 7.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Swagelok, AMETEK Cardinal UHP, HandyTube, Dockweiler, Valex, CoreDux, FITOK, WSG, Kunshan Kinglai Hygienic Materials, ASFLOW, Kuze |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |