What is Global Stainless Steel Tubing for Specialty Gas Market?

Global Stainless Steel Tubing for Specialty Gas Market refers to the industry focused on producing and supplying stainless steel tubes specifically designed for the transportation and containment of specialty gases. These gases are often used in high-tech industries such as semiconductors, pharmaceuticals, and aerospace, where purity and precision are paramount. The tubing must meet stringent standards to ensure that the gases remain uncontaminated and maintain their integrity throughout the process. Stainless steel is chosen for its durability, resistance to corrosion, and ability to withstand high pressures and temperatures. The market for these specialized tubes is driven by the growing demand for high-purity gases in various advanced manufacturing processes. As industries continue to innovate and require more precise and reliable gas delivery systems, the need for high-quality stainless steel tubing is expected to rise. This market encompasses a range of products, including different grades of stainless steel, each tailored to specific applications and requirements.

316L, 316L VIM/VAR in the Global Stainless Steel Tubing for Specialty Gas Market:

316L and 316L VIM/VAR are two specific grades of stainless steel that are highly relevant in the Global Stainless Steel Tubing for Specialty Gas Market. 316L is a low-carbon version of 316 stainless steel, which is known for its excellent corrosion resistance and high tensile strength. The low carbon content in 316L minimizes the risk of carbide precipitation during welding, which can lead to intergranular corrosion. This makes 316L an ideal choice for applications where welding is required, and the tubing must maintain its integrity in corrosive environments. On the other hand, 316L VIM/VAR stands for Vacuum Induction Melted/Vacuum Arc Remelted. This process involves melting the stainless steel in a vacuum to remove impurities and then remelting it using an electric arc in a vacuum to further refine the material. The result is a stainless steel with even fewer impurities and a more uniform microstructure, which enhances its mechanical properties and corrosion resistance. 316L VIM/VAR is often used in the most demanding applications where the highest levels of purity and performance are required. For instance, in the semiconductor industry, where even the smallest contamination can lead to significant defects in microchips, 316L VIM/VAR tubing ensures that the specialty gases remain uncontaminated. Similarly, in the pharmaceutical industry, where the purity of gases can impact the quality of the final product, 316L VIM/VAR provides the necessary assurance of cleanliness and reliability. The choice between 316L and 316L VIM/VAR depends on the specific requirements of the application, including factors such as the level of purity needed, the operating environment, and the mechanical stresses the tubing will face. Both grades offer excellent performance, but 316L VIM/VAR provides an extra level of assurance for the most critical applications.

Semiconductor, Special Gas Industries, Others in the Global Stainless Steel Tubing for Specialty Gas Market:

The usage of Global Stainless Steel Tubing for Specialty Gas Market spans several key areas, including the semiconductor industry, special gas industries, and other sectors. In the semiconductor industry, stainless steel tubing is crucial for the delivery of ultra-high purity gases used in the manufacturing of microchips and other electronic components. The precision and cleanliness of these gases are vital to ensure the quality and performance of the semiconductors. Stainless steel tubing, particularly grades like 316L and 316L VIM/VAR, is used to transport these gases without introducing any contaminants. The tubing must withstand high pressures and temperatures while maintaining the integrity of the gases, making stainless steel the material of choice. In special gas industries, which produce and handle gases for various high-tech applications, stainless steel tubing is essential for maintaining the purity and stability of the gases. These industries often deal with reactive or corrosive gases that require robust containment solutions. Stainless steel tubing provides the necessary resistance to corrosion and chemical reactions, ensuring that the gases remain uncontaminated and stable during storage and transport. Additionally, the durability and strength of stainless steel make it suitable for high-pressure applications, which are common in the special gas industries. Other sectors that utilize stainless steel tubing for specialty gases include aerospace, pharmaceuticals, and research laboratories. In aerospace, the precision and reliability of specialty gases are critical for various applications, including propulsion systems and environmental control systems. Stainless steel tubing ensures that these gases are delivered with the required purity and consistency. In the pharmaceutical industry, the purity of gases used in manufacturing processes can directly impact the quality and safety of the final products. Stainless steel tubing helps maintain the necessary standards of cleanliness and purity. Research laboratories also rely on stainless steel tubing for the accurate delivery of specialty gases used in experiments and analyses. The tubing's ability to maintain gas purity and withstand various environmental conditions makes it an indispensable component in these settings.

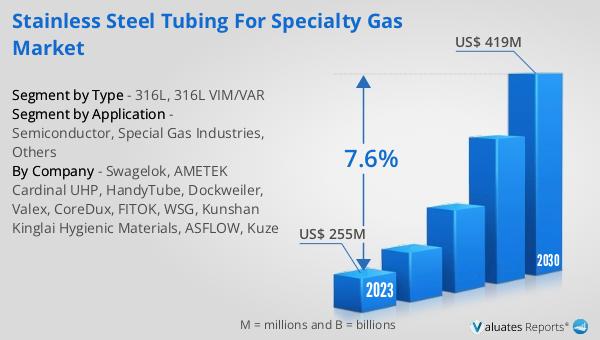

Global Stainless Steel Tubing for Specialty Gas Market Outlook:

The global Stainless Steel Tubing for Specialty Gas market was valued at US$ 255 million in 2023 and is anticipated to reach US$ 419 million by 2030, witnessing a CAGR of 7.6% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the industry, driven by the increasing demand for high-purity gases in various advanced manufacturing processes. The projected growth rate of 7.6% CAGR indicates a robust expansion, reflecting the rising importance of stainless steel tubing in ensuring the purity and integrity of specialty gases. As industries such as semiconductors, pharmaceuticals, and aerospace continue to evolve and require more precise and reliable gas delivery systems, the demand for high-quality stainless steel tubing is expected to grow. This market outlook underscores the critical role that stainless steel tubing plays in supporting the advancements in these high-tech industries. The anticipated increase in market value from US$ 255 million to US$ 419 million by 2030 demonstrates the growing recognition of the importance of maintaining gas purity and the reliance on stainless steel tubing to achieve this goal.

| Report Metric | Details |

| Report Name | Stainless Steel Tubing for Specialty Gas Market |

| Accounted market size in 2023 | US$ 255 million |

| Forecasted market size in 2030 | US$ 419 million |

| CAGR | 7.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Swagelok, AMETEK Cardinal UHP, HandyTube, Dockweiler, Valex, CoreDux, FITOK, WSG, Kunshan Kinglai Hygienic Materials, ASFLOW, Kuze |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |