What is Global Polyimide Wire Enamel Market?

The Global Polyimide Wire Enamel Market refers to the industry focused on the production and distribution of polyimide wire enamels, which are specialized coatings used to insulate wires. These enamels are known for their exceptional thermal stability, chemical resistance, and electrical insulation properties. They are primarily used in applications that require high performance and reliability, such as aerospace, industrial motors, and military applications. The market for polyimide wire enamels is driven by the increasing demand for advanced materials that can withstand extreme conditions and provide long-lasting performance. As industries continue to evolve and require more sophisticated technologies, the need for high-quality wire enamels is expected to grow, making the Global Polyimide Wire Enamel Market a critical component of modern manufacturing and engineering.

Copper Wires, Aluminum Wires in the Global Polyimide Wire Enamel Market:

Copper wires and aluminum wires are two primary types of conductors used in the Global Polyimide Wire Enamel Market. Copper wires are highly valued for their excellent electrical conductivity, flexibility, and durability. They are commonly used in a wide range of applications, including electrical wiring, telecommunications, and electronics. The use of polyimide wire enamel on copper wires enhances their performance by providing superior insulation, which helps to prevent electrical failures and extend the lifespan of the wires. This makes copper wires with polyimide enamel a preferred choice for high-performance applications where reliability and efficiency are paramount. On the other hand, aluminum wires are known for their lightweight and cost-effective properties. Although they have lower electrical conductivity compared to copper, aluminum wires are still widely used in various industries due to their affordability and ease of installation. The application of polyimide wire enamel on aluminum wires improves their thermal stability and resistance to corrosion, making them suitable for use in harsh environments. This combination of properties makes aluminum wires with polyimide enamel an attractive option for applications where weight and cost are critical factors. Both copper and aluminum wires play a significant role in the Global Polyimide Wire Enamel Market, catering to different needs and requirements across various industries. The choice between copper and aluminum wires often depends on the specific application and the desired balance between performance, cost, and weight. As the demand for advanced materials continues to grow, the market for polyimide wire enamels on both copper and aluminum wires is expected to expand, driven by the need for reliable and efficient electrical insulation solutions.

Aerospace, Industrial Motor, Military Application, Others in the Global Polyimide Wire Enamel Market:

The usage of Global Polyimide Wire Enamel Market in aerospace, industrial motor, military applications, and other areas highlights the versatility and importance of this specialized coating. In the aerospace industry, polyimide wire enamels are used to insulate wires in aircraft and spacecraft, where they must withstand extreme temperatures, vibrations, and other harsh conditions. The exceptional thermal stability and chemical resistance of polyimide enamels make them ideal for these demanding environments, ensuring the reliability and safety of critical electrical systems. In industrial motors, polyimide wire enamels are used to insulate the windings of electric motors, which are subjected to high temperatures and mechanical stresses during operation. The use of polyimide enamels helps to improve the efficiency and longevity of these motors by providing superior insulation and protection against thermal degradation. This is particularly important in industries where motors are used continuously and must perform reliably under challenging conditions. Military applications also benefit from the use of polyimide wire enamels, as they provide the necessary insulation and protection for electrical systems in military vehicles, equipment, and communication devices. The durability and reliability of polyimide enamels make them suitable for use in harsh environments, where they must withstand extreme temperatures, moisture, and mechanical stresses. Other areas where polyimide wire enamels are used include medical devices, automotive applications, and consumer electronics. In medical devices, polyimide enamels provide the necessary insulation and protection for wires used in diagnostic and therapeutic equipment, ensuring their safe and reliable operation. In the automotive industry, polyimide wire enamels are used to insulate wires in electric vehicles and other advanced automotive systems, where they must withstand high temperatures and mechanical stresses. In consumer electronics, polyimide enamels are used to insulate wires in devices such as smartphones, tablets, and laptops, providing the necessary protection and reliability for these high-performance products. The versatility and high-performance characteristics of polyimide wire enamels make them an essential component in a wide range of applications, driving the growth and development of the Global Polyimide Wire Enamel Market.

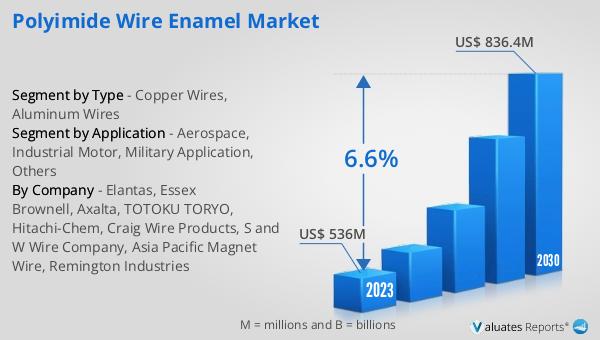

Global Polyimide Wire Enamel Market Outlook:

The global Polyimide Wire Enamel market was valued at US$ 536 million in 2023 and is anticipated to reach US$ 836.4 million by 2030, witnessing a CAGR of 6.6% during the forecast period 2024-2030. This market outlook indicates a significant growth trajectory for the polyimide wire enamel industry, driven by increasing demand for high-performance insulation materials across various sectors. The projected growth reflects the expanding applications of polyimide wire enamels in industries such as aerospace, industrial motors, military applications, and more. As these industries continue to evolve and require more advanced and reliable materials, the demand for polyimide wire enamels is expected to rise. The market's growth is also supported by ongoing technological advancements and innovations in the production and application of polyimide wire enamels, which enhance their performance and broaden their range of uses. This positive market outlook underscores the importance of polyimide wire enamels in modern manufacturing and engineering, highlighting their critical role in ensuring the reliability and efficiency of electrical systems in various high-performance applications.

| Report Metric | Details |

| Report Name | Polyimide Wire Enamel Market |

| Accounted market size in 2023 | US$ 536 million |

| Forecasted market size in 2030 | US$ 836.4 million |

| CAGR | 6.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Elantas, Essex Brownell, Axalta, TOTOKU TORYO, Hitachi-Chem, Craig Wire Products, S and W Wire Company, Asia Pacific Magnet Wire, Remington Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |