What is Global Polyimide Magnet Wire Market?

The Global Polyimide Magnet Wire Market refers to the worldwide industry focused on the production and distribution of magnet wires insulated with polyimide. Polyimide is a high-performance polymer known for its exceptional thermal stability, mechanical strength, and chemical resistance. These properties make polyimide magnet wires particularly suitable for applications requiring high reliability and durability under extreme conditions. The market encompasses various sectors, including aerospace, industrial motors, military applications, and other specialized fields. The demand for polyimide magnet wires is driven by their ability to perform in high-temperature environments and their resistance to wear and tear, which ensures longevity and efficiency in critical applications. As industries continue to advance technologically, the need for robust and reliable materials like polyimide magnet wires is expected to grow, making this market a vital component of modern industrial and technological infrastructure.

Copper Wires, Aluminum Wires in the Global Polyimide Magnet Wire Market:

Copper wires and aluminum wires are two primary types of conductors used in the Global Polyimide Magnet Wire Market. Copper wires are highly favored due to their excellent electrical conductivity, thermal conductivity, and flexibility. These properties make copper wires ideal for applications where efficient energy transmission and minimal energy loss are crucial. Copper's high melting point and resistance to corrosion further enhance its suitability for use in harsh environments, such as those found in aerospace and military applications. On the other hand, aluminum wires are valued for their lightweight nature and cost-effectiveness. Although aluminum has lower electrical conductivity compared to copper, it is still widely used in applications where weight reduction is a priority, such as in the automotive and aerospace industries. Aluminum's lower density allows for the production of lighter components, which can contribute to overall system efficiency and performance. Both copper and aluminum wires, when insulated with polyimide, benefit from the polymer's high thermal stability and mechanical strength. This combination ensures that the wires can withstand high temperatures and mechanical stresses, making them reliable choices for demanding applications. The choice between copper and aluminum wires often depends on the specific requirements of the application, including factors such as conductivity, weight, cost, and environmental conditions. In summary, the Global Polyimide Magnet Wire Market leverages the unique properties of both copper and aluminum wires to meet the diverse needs of various industries, ensuring efficient and reliable performance in critical applications.

Aerospace, Industrial Motor, Military Application, Others in the Global Polyimide Magnet Wire Market:

The usage of Global Polyimide Magnet Wire Market spans several key areas, including aerospace, industrial motors, military applications, and others. In the aerospace sector, polyimide magnet wires are essential due to their ability to withstand extreme temperatures and harsh environmental conditions. These wires are used in various components, such as avionics, control systems, and power distribution networks, where reliability and performance are critical. The high thermal stability and mechanical strength of polyimide magnet wires ensure that they can endure the rigorous demands of aerospace applications, contributing to the safety and efficiency of aircraft systems. In industrial motors, polyimide magnet wires play a crucial role in ensuring the efficient operation of electric motors used in manufacturing, automation, and other industrial processes. The wires' excellent thermal and mechanical properties enable them to handle high power loads and continuous operation without degradation, leading to improved motor performance and longevity. Military applications also benefit significantly from polyimide magnet wires, as these wires are used in various defense systems, including radar, communication equipment, and weaponry. The durability and reliability of polyimide magnet wires are vital in military settings, where equipment must perform flawlessly under extreme conditions. Additionally, polyimide magnet wires are used in other specialized fields, such as medical devices, renewable energy systems, and automotive applications. In medical devices, the wires' biocompatibility and resistance to sterilization processes make them suitable for use in critical medical equipment. In renewable energy systems, polyimide magnet wires are used in wind turbines and solar panels, where their ability to withstand harsh environmental conditions ensures reliable energy generation. In the automotive industry, these wires are used in electric vehicles and advanced driver-assistance systems (ADAS), contributing to the efficiency and safety of modern vehicles. Overall, the Global Polyimide Magnet Wire Market serves a wide range of industries, providing high-performance solutions that meet the demanding requirements of various applications.

Global Polyimide Magnet Wire Market Outlook:

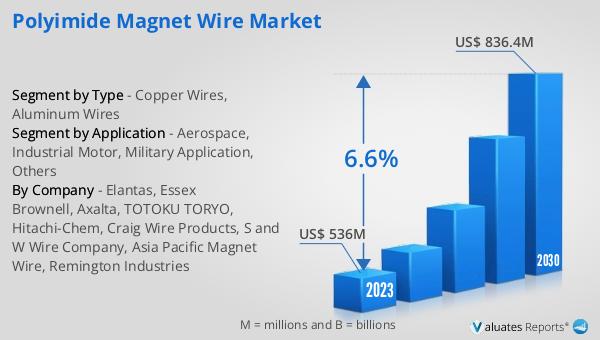

The global Polyimide Magnet Wire market was valued at US$ 536 million in 2023 and is anticipated to reach US$ 836.4 million by 2030, witnessing a CAGR of 6.6% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the polyimide magnet wire industry over the next several years. The increasing demand for high-performance materials in various sectors, including aerospace, industrial motors, military applications, and others, is driving this growth. Polyimide magnet wires, known for their exceptional thermal stability, mechanical strength, and chemical resistance, are becoming increasingly essential in applications that require reliable and durable performance under extreme conditions. As industries continue to advance technologically, the need for robust and efficient materials like polyimide magnet wires is expected to rise, contributing to the market's expansion. The projected growth rate of 6.6% CAGR indicates a steady increase in market value, reflecting the ongoing advancements and innovations in the field. This positive market outlook underscores the importance of polyimide magnet wires in modern industrial and technological infrastructure, highlighting their critical role in ensuring the efficiency and reliability of various applications.

| Report Metric | Details |

| Report Name | Polyimide Magnet Wire Market |

| Accounted market size in 2023 | US$ 536 million |

| Forecasted market size in 2030 | US$ 836.4 million |

| CAGR | 6.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Elantas, Essex Brownell, Axalta, TOTOKU TORYO, Hitachi-Chem, Craig Wire Products, S and W Wire Company, Asia Pacific Magnet Wire, Remington Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |