What is Global Polyester Dipped Cord Market?

The Global Polyester Dipped Cord Market refers to the industry that produces and sells polyester cords treated with a special dipping process to enhance their strength, durability, and resistance to various environmental factors. These cords are primarily used in industrial applications where high performance and reliability are crucial. The dipping process involves coating the polyester fibers with a chemical solution that improves their adhesion properties, making them suitable for use in products like tires, conveyor belts, and hoses. This market is driven by the increasing demand for durable and high-performance materials in various industries, including automotive, manufacturing, and construction. The global market for polyester dipped cords is characterized by a diverse range of products, each tailored to meet specific industrial needs. The market is also influenced by technological advancements and innovations aimed at improving the quality and performance of polyester dipped cords.

High Modulus Low Shrinkage, High Strength Type in the Global Polyester Dipped Cord Market:

High Modulus Low Shrinkage (HMLS) and High Strength types are two significant categories within the Global Polyester Dipped Cord Market. HMLS polyester cords are designed to offer superior dimensional stability and minimal shrinkage under high temperatures and stress. This makes them ideal for applications where maintaining shape and size is critical, such as in high-performance tires and conveyor belts. The low shrinkage property ensures that the cords do not contract significantly when exposed to heat, thereby maintaining the integrity and performance of the end product. On the other hand, High Strength polyester cords are engineered to provide exceptional tensile strength and durability. These cords are capable of withstanding extreme forces and pressures, making them suitable for heavy-duty applications like industrial hoses and high-load conveyor systems. The high strength characteristic ensures that the cords can endure substantial mechanical stress without breaking or deforming, thereby enhancing the longevity and reliability of the products they are used in. Both HMLS and High Strength polyester cords undergo a rigorous dipping process that involves coating the fibers with a specialized chemical solution. This process not only enhances the physical properties of the cords but also improves their resistance to environmental factors such as moisture, chemicals, and UV radiation. The dipping solution typically contains resins and other additives that form a protective layer around the polyester fibers, thereby increasing their durability and performance. The choice between HMLS and High Strength polyester cords depends on the specific requirements of the application. For instance, in the automotive industry, HMLS cords are preferred for tire reinforcement due to their ability to maintain shape and size under high temperatures and stress. This ensures that the tires provide consistent performance and safety over their lifespan. In contrast, High Strength cords are favored in applications where maximum tensile strength and durability are required, such as in heavy-duty conveyor belts and industrial hoses. The global market for these specialized polyester cords is driven by the increasing demand for high-performance materials in various industrial sectors. Technological advancements and innovations in the dipping process and chemical formulations are also contributing to the growth of this market. Manufacturers are continually investing in research and development to enhance the properties of polyester dipped cords and meet the evolving needs of different industries. The market is also characterized by a high level of competition, with numerous players offering a wide range of products to cater to diverse industrial applications. In summary, High Modulus Low Shrinkage and High Strength polyester cords are essential components in the Global Polyester Dipped Cord Market. Their unique properties make them suitable for a wide range of industrial applications, from automotive tires to heavy-duty conveyor systems. The ongoing advancements in dipping technology and chemical formulations are expected to further enhance the performance and durability of these cords, thereby driving the growth of the market.

Conveyor Belts, Hose, Tire, Others in the Global Polyester Dipped Cord Market:

The Global Polyester Dipped Cord Market finds extensive usage in various industrial applications, including conveyor belts, hoses, tires, and other specialized products. In the context of conveyor belts, polyester dipped cords are used as reinforcement materials to enhance the strength, durability, and performance of the belts. The high tensile strength and resistance to environmental factors such as moisture and chemicals make these cords ideal for use in conveyor systems that operate under harsh conditions. The cords help maintain the structural integrity of the belts, ensuring smooth and efficient material handling in industries such as mining, manufacturing, and logistics. In the hose industry, polyester dipped cords are used to reinforce hoses, making them capable of withstanding high pressures and mechanical stress. These cords provide the necessary strength and flexibility to the hoses, enabling them to perform effectively in demanding applications such as hydraulic systems, industrial machinery, and automotive components. The dipping process enhances the adhesion properties of the cords, ensuring a strong bond with the hose materials and preventing delamination or failure under extreme conditions. The tire industry is another significant user of polyester dipped cords. These cords are used as reinforcement materials in the construction of tires, providing the necessary strength and stability to withstand the stresses and strains of road conditions. The high modulus low shrinkage (HMLS) properties of the cords ensure that the tires maintain their shape and performance even under high temperatures and loads. This contributes to the overall safety, durability, and performance of the tires, making them suitable for use in various types of vehicles, from passenger cars to heavy-duty trucks. Apart from conveyor belts, hoses, and tires, polyester dipped cords are also used in other specialized applications. For instance, they are used in the production of V-belts, timing belts, and other power transmission components. The high strength and durability of the cords make them ideal for use in these applications, where reliable performance and long service life are critical. Additionally, polyester dipped cords are used in the construction of geotextiles, which are used in civil engineering projects for soil stabilization, erosion control, and drainage systems. The versatility and high-performance characteristics of polyester dipped cords make them indispensable in various industrial applications. The ongoing advancements in dipping technology and chemical formulations are further enhancing the properties of these cords, making them more suitable for a wider range of applications. The global market for polyester dipped cords is driven by the increasing demand for durable and high-performance materials in various industries, including automotive, manufacturing, construction, and civil engineering. In summary, the Global Polyester Dipped Cord Market plays a crucial role in enhancing the performance and durability of various industrial products, including conveyor belts, hoses, tires, and other specialized components. The unique properties of polyester dipped cords, such as high tensile strength, low shrinkage, and resistance to environmental factors, make them ideal for use in demanding applications. The ongoing advancements in dipping technology and chemical formulations are expected to further drive the growth of this market, meeting the evolving needs of different industries.

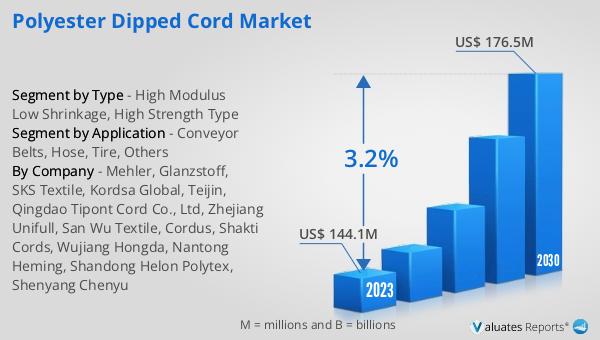

Global Polyester Dipped Cord Market Outlook:

The global Polyester Dipped Cord market was valued at US$ 144.1 million in 2023 and is anticipated to reach US$ 176.5 million by 2030, witnessing a CAGR of 3.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for high-performance and durable materials in various industrial applications. The market's valuation reflects the significant role that polyester dipped cords play in enhancing the strength, durability, and performance of products such as tires, conveyor belts, and hoses. The projected growth rate underscores the ongoing advancements in dipping technology and chemical formulations, which are continually improving the properties of polyester dipped cords. As industries such as automotive, manufacturing, and construction continue to seek reliable and high-performance materials, the demand for polyester dipped cords is expected to rise. The market's growth is also supported by the increasing focus on quality and performance in industrial applications, where the unique properties of polyester dipped cords, such as high tensile strength, low shrinkage, and resistance to environmental factors, are highly valued. In summary, the global Polyester Dipped Cord market is poised for steady growth, driven by the rising demand for durable and high-performance materials in various industrial sectors. The market's valuation and projected growth rate highlight the importance of polyester dipped cords in enhancing the performance and reliability of industrial products.

| Report Metric | Details |

| Report Name | Polyester Dipped Cord Market |

| Accounted market size in 2023 | US$ 144.1 million |

| Forecasted market size in 2030 | US$ 176.5 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mehler, Glanzstoff, SKS Textile, Kordsa Global, Teijin, Qingdao Tipont Cord Co., Ltd, Zhejiang Unifull, San Wu Textile, Cordus, Shakti Cords, Wujiang Hongda, Nantong Heming, Shandong Helon Polytex, Shenyang Chenyu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |