What is Global Nylon Single End Cord Market?

The Global Nylon Single End Cord Market refers to the worldwide industry involved in the production and distribution of nylon single end cords. These cords are essentially high-strength, durable threads made from nylon, a type of synthetic polymer. They are used in various industrial applications due to their excellent tensile strength, elasticity, and resistance to wear and tear. The market encompasses a wide range of activities, including the manufacturing of raw nylon materials, the processing of these materials into single end cords, and the distribution of the final products to various industries. The demand for nylon single end cords is driven by their extensive use in sectors such as automotive, aerospace, and construction, where they are used in products like tires, conveyor belts, and hoses. The market is characterized by a mix of large multinational corporations and smaller regional players, all competing to meet the growing demand for high-quality nylon cords. Technological advancements and innovations in manufacturing processes are also playing a significant role in shaping the market dynamics, making it a vibrant and evolving industry.

High Strength Nylon, Ordinary Nylon in the Global Nylon Single End Cord Market:

High Strength Nylon and Ordinary Nylon are two key segments within the Global Nylon Single End Cord Market, each serving distinct purposes based on their unique properties. High Strength Nylon is engineered to offer superior tensile strength, making it ideal for applications that require durability and resistance to extreme conditions. This type of nylon is often used in heavy-duty industrial applications such as conveyor belts, where the material must withstand significant stress and abrasion. The high strength variant is also preferred in the automotive industry for tire manufacturing, as it provides the necessary reinforcement to ensure safety and longevity. On the other hand, Ordinary Nylon, while still robust, does not offer the same level of tensile strength as its high-strength counterpart. It is more commonly used in applications where extreme durability is not as critical. For instance, ordinary nylon is often utilized in the production of hoses and other flexible tubing, where its elasticity and resistance to chemicals are more important than its tensile strength. Both types of nylon share common characteristics such as resistance to wear and tear, elasticity, and the ability to withstand various environmental conditions. However, the choice between high strength and ordinary nylon largely depends on the specific requirements of the application. In the context of the Global Nylon Single End Cord Market, manufacturers must carefully consider these factors to produce cords that meet the diverse needs of their customers. The market for high strength nylon is generally more specialized, with higher production costs and more stringent quality control measures. In contrast, the market for ordinary nylon is broader, catering to a wider range of applications and often benefiting from economies of scale. Despite these differences, both segments are essential to the overall market, contributing to its growth and diversification. As industries continue to evolve and new applications for nylon single end cords are discovered, the demand for both high strength and ordinary nylon is expected to remain strong. This ongoing demand underscores the importance of innovation and adaptability in the Global Nylon Single End Cord Market, as manufacturers strive to meet the ever-changing needs of their customers.

Conveyor Belts, Hose, Tire, Others in the Global Nylon Single End Cord Market:

The Global Nylon Single End Cord Market finds extensive usage in various industrial applications, including conveyor belts, hoses, tires, and other specialized products. In the realm of conveyor belts, nylon single end cords are prized for their exceptional tensile strength and durability. These cords provide the necessary reinforcement to ensure that conveyor belts can handle heavy loads and resist wear and tear over extended periods. The elasticity of nylon also allows conveyor belts to maintain their shape and functionality, even under constant stress. This makes them indispensable in industries such as mining, manufacturing, and logistics, where conveyor belts are a critical component of the operational infrastructure. In the production of hoses, nylon single end cords offer a unique combination of flexibility and strength. Hoses reinforced with nylon cords can withstand high pressure and resist kinking, making them ideal for use in hydraulic systems, fuel lines, and other demanding applications. The chemical resistance of nylon further enhances the durability of these hoses, ensuring they can handle a wide range of fluids without degrading. This versatility makes nylon-reinforced hoses a popular choice in industries such as automotive, aerospace, and agriculture. When it comes to tire manufacturing, nylon single end cords play a crucial role in providing the necessary reinforcement to ensure safety and performance. The high tensile strength of nylon cords helps tires maintain their shape and integrity under various driving conditions, from high-speed highway travel to off-road adventures. This reinforcement is essential for preventing blowouts and ensuring a smooth, stable ride. Additionally, the elasticity of nylon allows tires to absorb shocks and vibrations, enhancing overall driving comfort. Beyond these primary applications, nylon single end cords are also used in a variety of other specialized products. For example, they are employed in the production of industrial fabrics, where their strength and durability are essential for creating long-lasting materials. They are also used in the construction of fishing nets, where their resistance to abrasion and environmental conditions ensures they can withstand the rigors of marine environments. In summary, the Global Nylon Single End Cord Market serves a wide range of industries, providing essential reinforcement and durability to products that are critical to modern infrastructure and daily life. The versatility and reliability of nylon single end cords make them a valuable component in numerous applications, driving ongoing demand and innovation in the market.

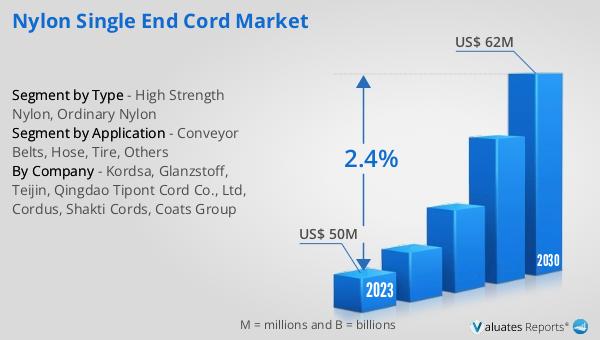

Global Nylon Single End Cord Market Outlook:

The global market for Nylon Single End Cord was valued at $50 million in 2023 and is projected to grow to $62 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.4% over the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-quality nylon cords across various industries. The market's expansion can be attributed to several factors, including advancements in manufacturing technologies, the rising need for durable and high-strength materials, and the growing applications of nylon cords in sectors such as automotive, aerospace, and construction. As industries continue to evolve and new uses for nylon single end cords are discovered, the market is expected to maintain its upward trajectory. The steady growth rate also highlights the resilience of the market, even in the face of economic fluctuations and changing industry dynamics. Manufacturers and stakeholders in the Global Nylon Single End Cord Market are likely to benefit from this sustained demand, provided they continue to innovate and adapt to the evolving needs of their customers.

| Report Metric | Details |

| Report Name | Nylon Single End Cord Market |

| Accounted market size in 2023 | US$ 50 million |

| Forecasted market size in 2030 | US$ 62 million |

| CAGR | 2.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kordsa, Glanzstoff, Teijin, Qingdao Tipont Cord Co., Ltd, Cordus, Shakti Cords, Coats Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |