What is Global Medium Pressure Injection Molding Machine Market?

The Global Medium Pressure Injection Molding Machine Market refers to the worldwide industry focused on the production and sale of injection molding machines that operate at medium pressure levels. These machines are essential in manufacturing various plastic products by injecting molten plastic into molds under controlled pressure. The market encompasses a wide range of industries, including automotive, electronics, consumer goods, and packaging, among others. Medium pressure injection molding machines are particularly valued for their ability to produce high-quality, precise, and durable plastic components. They offer a balance between high-pressure and low-pressure machines, making them versatile and cost-effective for many applications. The market is driven by technological advancements, increasing demand for plastic products, and the need for efficient and sustainable manufacturing processes. As industries continue to innovate and expand, the demand for medium pressure injection molding machines is expected to grow, making this market a critical component of the global manufacturing landscape.

Hydraulic, Electric, Hybrid in the Global Medium Pressure Injection Molding Machine Market:

Hydraulic, electric, and hybrid injection molding machines are the three primary types of machines used in the Global Medium Pressure Injection Molding Machine Market. Hydraulic machines are the most traditional and widely used type. They operate using hydraulic cylinders to generate the necessary pressure for molding. These machines are known for their robustness, reliability, and ability to handle large and complex molds. They are particularly suitable for applications requiring high clamping force and are often used in the automotive and heavy-duty industrial sectors. However, hydraulic machines can be less energy-efficient and produce more noise compared to their electric and hybrid counterparts. Electric injection molding machines, on the other hand, use electric servo motors to drive the various components of the machine. These machines are known for their precision, energy efficiency, and lower operational noise. They offer faster cycle times and better repeatability, making them ideal for high-precision applications such as electronics, medical devices, and small consumer goods. Electric machines also have a smaller environmental footprint due to their lower energy consumption and reduced need for hydraulic oil. However, they can be more expensive to purchase initially compared to hydraulic machines. Hybrid injection molding machines combine the best features of both hydraulic and electric machines. They use a combination of hydraulic and electric drives to optimize performance, energy efficiency, and cost-effectiveness. Hybrid machines offer the high clamping force and robustness of hydraulic machines while incorporating the precision and energy efficiency of electric machines. This makes them versatile and suitable for a wide range of applications, from automotive parts to consumer electronics. They are particularly beneficial in scenarios where both high performance and energy efficiency are required. In summary, each type of injection molding machine has its own set of advantages and is suited to different applications within the Global Medium Pressure Injection Molding Machine Market. Hydraulic machines are robust and reliable, making them ideal for heavy-duty applications. Electric machines offer precision and energy efficiency, suitable for high-precision and environmentally conscious applications. Hybrid machines provide a balanced solution, combining the strengths of both hydraulic and electric machines to meet diverse manufacturing needs. As the market continues to evolve, the choice of machine type will depend on specific application requirements, cost considerations, and sustainability goals.

General Plastics Industry, Automobile Industry, Home Appliance Industry, Others in the Global Medium Pressure Injection Molding Machine Market:

The Global Medium Pressure Injection Molding Machine Market finds extensive usage across various industries, including the general plastics industry, automobile industry, home appliance industry, and others. In the general plastics industry, these machines are used to manufacture a wide range of plastic products, from everyday household items to specialized industrial components. The versatility and precision of medium pressure injection molding machines make them ideal for producing high-quality plastic parts with intricate designs and tight tolerances. This industry benefits from the machines' ability to handle different types of plastics and produce consistent results, ensuring the production of durable and reliable products. In the automobile industry, medium pressure injection molding machines play a crucial role in manufacturing various automotive components, such as dashboards, bumpers, interior panels, and under-the-hood parts. The automotive sector demands high precision, strength, and durability in its components, and these machines are capable of meeting these stringent requirements. The ability to produce complex shapes and lightweight parts also contributes to the overall efficiency and performance of vehicles. Additionally, the use of these machines helps in reducing production costs and improving the sustainability of automotive manufacturing processes. The home appliance industry also relies heavily on medium pressure injection molding machines for the production of various components used in household appliances such as refrigerators, washing machines, microwaves, and air conditioners. These machines enable manufacturers to produce parts with high precision and consistency, ensuring the proper functioning and longevity of the appliances. The ability to mold different types of plastics allows for the production of components with specific properties, such as heat resistance, impact strength, and aesthetic appeal. This versatility is essential in meeting the diverse requirements of the home appliance industry. Other industries that utilize medium pressure injection molding machines include the electronics, medical, and packaging sectors. In the electronics industry, these machines are used to produce components such as connectors, housings, and circuit board parts, which require high precision and reliability. The medical industry benefits from the machines' ability to produce sterile and biocompatible components for medical devices and equipment. In the packaging industry, medium pressure injection molding machines are used to manufacture various types of packaging materials, including bottles, caps, and containers, ensuring high-quality and consistent production. Overall, the Global Medium Pressure Injection Molding Machine Market serves a wide range of industries by providing versatile, precise, and efficient manufacturing solutions. The ability to produce high-quality plastic components with intricate designs and tight tolerances makes these machines indispensable in various applications. As industries continue to innovate and expand, the demand for medium pressure injection molding machines is expected to grow, further driving the market's development and adoption.

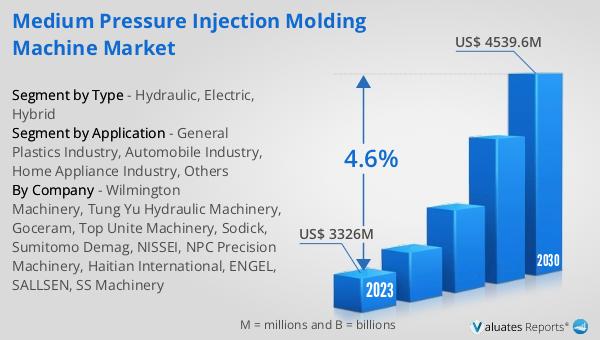

Global Medium Pressure Injection Molding Machine Market Outlook:

The global Medium Pressure Injection Molding Machine market was valued at US$ 3326 million in 2023 and is anticipated to reach US$ 4539.6 million by 2030, witnessing a CAGR of 4.6% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the medium pressure injection molding machine industry over the next several years. The increasing demand for high-quality plastic products across various industries, coupled with advancements in injection molding technology, is expected to drive this growth. The market's expansion is also supported by the rising need for efficient and sustainable manufacturing processes, which medium pressure injection molding machines are well-equipped to provide. As industries continue to seek innovative solutions to meet their production needs, the medium pressure injection molding machine market is poised for significant growth and development.

| Report Metric | Details |

| Report Name | Medium Pressure Injection Molding Machine Market |

| Accounted market size in 2023 | US$ 3326 million |

| Forecasted market size in 2030 | US$ 4539.6 million |

| CAGR | 4.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Wilmington Machinery, Tung Yu Hydraulic Machinery, Goceram, Top Unite Machinery, Sodick, Sumitomo Demag, NISSEI, NPC Precision Machinery, Haitian International, ENGEL, SALLSEN, SS Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |