What is Global Low Pressure Injection Molding Machine Market?

The global Low Pressure Injection Molding Machine market is a specialized segment within the broader injection molding industry. These machines are designed to operate at lower pressures compared to traditional injection molding machines, which makes them ideal for specific applications where high pressure could damage the mold or the material being used. Low pressure injection molding is particularly useful for encapsulating delicate electronic components, creating overmolded parts, and producing items with intricate designs. The market for these machines is growing due to their ability to produce high-quality parts with reduced material stress and lower energy consumption. Additionally, the versatility of low pressure injection molding machines allows them to be used with a wide range of materials, including thermoplastics, thermosets, and elastomers. This adaptability makes them a valuable asset in various industries, from automotive to consumer electronics. As manufacturers continue to seek ways to improve efficiency and product quality, the demand for low pressure injection molding machines is expected to rise.

Hydraulic, Electric, Hybrid in the Global Low Pressure Injection Molding Machine Market:

Hydraulic, electric, and hybrid low pressure injection molding machines each offer unique advantages and are tailored to meet different industrial needs. Hydraulic machines are the traditional workhorses of the injection molding industry. They use hydraulic cylinders to generate the force needed to inject the material into the mold. These machines are known for their robustness and ability to handle large, heavy molds. They are particularly well-suited for applications requiring high clamping force and are often used in the automotive and heavy equipment industries. However, hydraulic machines can be less energy-efficient and may require more maintenance due to the complexity of their hydraulic systems. Electric low pressure injection molding machines, on the other hand, use electric servo motors to drive the injection process. These machines are known for their precision, energy efficiency, and lower operational noise. Electric machines are ideal for applications requiring high precision and repeatability, such as the production of small, intricate parts for the electronics and medical industries. They also offer faster cycle times and reduced energy consumption, making them a more environmentally friendly option. However, electric machines can be more expensive upfront compared to hydraulic machines, which can be a consideration for some manufacturers. Hybrid low pressure injection molding machines combine the best features of both hydraulic and electric machines. They use a combination of hydraulic and electric drives to optimize performance and efficiency. For example, a hybrid machine might use an electric motor for the injection unit to achieve high precision and speed, while using hydraulic cylinders for the clamping unit to provide the necessary force. This combination allows hybrid machines to offer a balance of power, precision, and energy efficiency. They are versatile and can be used in a wide range of applications, from automotive parts to consumer goods. Hybrid machines are often seen as a middle ground, offering the benefits of both hydraulic and electric machines without some of their respective drawbacks. In summary, the choice between hydraulic, electric, and hybrid low pressure injection molding machines depends on the specific needs of the application. Hydraulic machines are best for heavy-duty applications requiring high clamping force, electric machines excel in precision and energy efficiency, and hybrid machines offer a balanced solution that combines the strengths of both. As the global market for low pressure injection molding machines continues to grow, manufacturers will have more options to choose from, allowing them to select the best machine for their specific requirements.

General Plastics Industry, Automobile Industry, Home Appliance Industry, Others in the Global Low Pressure Injection Molding Machine Market:

The global low pressure injection molding machine market finds extensive usage across various industries, each benefiting from the unique capabilities of these machines. In the general plastics industry, low pressure injection molding machines are used to produce a wide range of plastic products, from simple household items to complex industrial components. The ability to mold intricate designs and overmold different materials makes these machines highly versatile. They are particularly useful for producing parts that require a high degree of precision and consistency, such as connectors, switches, and other small components. The reduced material stress and lower energy consumption associated with low pressure injection molding also contribute to cost savings and improved product quality. In the automobile industry, low pressure injection molding machines are used to manufacture a variety of components, including interior and exterior parts, under-the-hood components, and electrical connectors. The automotive industry demands high-quality, durable parts that can withstand harsh conditions, and low pressure injection molding machines are well-suited to meet these requirements. The ability to produce parts with complex geometries and overmold different materials allows manufacturers to create innovative designs and improve the performance of automotive components. Additionally, the energy efficiency of low pressure injection molding machines aligns with the automotive industry's focus on sustainability and reducing environmental impact. The home appliance industry also benefits from the capabilities of low pressure injection molding machines. These machines are used to produce a wide range of components for household appliances, such as washing machines, refrigerators, and air conditioners. The precision and consistency offered by low pressure injection molding ensure that parts fit together seamlessly and function reliably. The ability to overmold different materials allows manufacturers to create components with enhanced properties, such as improved insulation or increased durability. The energy efficiency of low pressure injection molding machines also contributes to cost savings and supports the industry's efforts to produce more environmentally friendly products. Beyond these specific industries, low pressure injection molding machines are used in various other applications, including consumer electronics, medical devices, and packaging. In the consumer electronics industry, these machines are used to produce small, intricate parts that require high precision and consistency. The medical device industry benefits from the ability to produce components with complex geometries and overmold different materials, which is essential for creating advanced medical devices. In the packaging industry, low pressure injection molding machines are used to produce high-quality, durable packaging solutions that protect products during transportation and storage. The versatility and efficiency of low pressure injection molding machines make them a valuable asset across a wide range of industries, driving their adoption and growth in the global market.

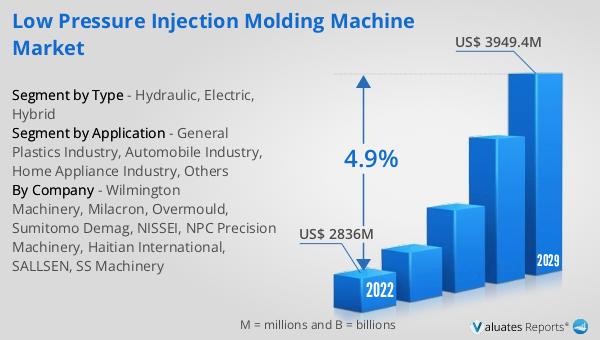

Global Low Pressure Injection Molding Machine Market Outlook:

The global Low Pressure Injection Molding Machine market was valued at US$ 2836 million in 2023 and is anticipated to reach US$ 3949.4 million by 2030, witnessing a CAGR of 4.9% during the forecast period from 2024 to 2030. This market outlook highlights the significant growth potential of low pressure injection molding machines over the next several years. The increasing demand for high-quality, precision-molded parts across various industries is driving the adoption of these machines. Manufacturers are continually seeking ways to improve efficiency, reduce costs, and enhance product quality, and low pressure injection molding machines offer a viable solution to meet these objectives. The projected growth in market value reflects the expanding applications and benefits of these machines, as well as the ongoing advancements in technology that are making them more accessible and efficient. As industries such as automotive, electronics, and consumer goods continue to evolve and innovate, the demand for low pressure injection molding machines is expected to rise, contributing to the overall growth of the market.

| Report Metric | Details |

| Report Name | Low Pressure Injection Molding Machine Market |

| Accounted market size in 2023 | US$ 2836 million |

| Forecasted market size in 2030 | US$ 3949.4 million |

| CAGR | 4.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Wilmington Machinery, Milacron, Overmould, Sumitomo Demag, NISSEI, NPC Precision Machinery, Haitian International, SALLSEN, SS Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |