What is Global Low Pressure Ceramic Injection Molding Market?

The Global Low Pressure Ceramic Injection Molding (LPCIM) Market is a specialized segment within the broader ceramics industry, focusing on the production of intricate and high-precision ceramic components. This market leverages the low-pressure injection molding process, which allows for the creation of complex shapes and fine details that are difficult to achieve with traditional ceramic manufacturing methods. The process involves mixing ceramic powders with a binder to form a feedstock, which is then injected into molds under low pressure. After molding, the binder is removed, and the ceramic part is sintered to achieve its final properties. This technique is particularly advantageous for producing small to medium-sized parts with high dimensional accuracy and excellent surface finish. The LPCIM market serves various industries, including electronics, medical, aerospace, and automotive, where the demand for high-performance ceramic components is growing. The ability to produce parts with intricate geometries and superior material properties makes LPCIM a valuable technology in these sectors.

Alumina, Yttria-Stabilized Zirconia (YTZP), Zirconia Toughened Alumina (ZTA), Others in the Global Low Pressure Ceramic Injection Molding Market:

Alumina, Yttria-Stabilized Zirconia (YTZP), Zirconia Toughened Alumina (ZTA), and other materials play crucial roles in the Global Low Pressure Ceramic Injection Molding Market. Alumina, or aluminum oxide, is one of the most widely used ceramics due to its excellent mechanical properties, high thermal conductivity, and resistance to wear and corrosion. It is commonly used in applications requiring high strength and durability, such as electrical insulators, cutting tools, and biomedical implants. Yttria-Stabilized Zirconia (YTZP) is another important material, known for its exceptional toughness, high fracture resistance, and thermal stability. YTZP is often used in applications where high mechanical stress and thermal shock resistance are critical, such as in dental implants, fuel cell components, and aerospace parts. Zirconia Toughened Alumina (ZTA) combines the properties of both alumina and zirconia, offering enhanced toughness and strength compared to pure alumina. This makes ZTA suitable for applications that require a balance of hardness and fracture toughness, such as in cutting tools, wear-resistant components, and medical devices. Other materials used in LPCIM include silicon nitride, silicon carbide, and various advanced ceramics, each offering unique properties tailored to specific applications. Silicon nitride, for example, is known for its high strength, thermal shock resistance, and low thermal expansion, making it ideal for use in high-temperature environments and mechanical components. Silicon carbide, on the other hand, is valued for its extreme hardness, high thermal conductivity, and chemical resistance, making it suitable for abrasive and high-wear applications. The choice of material in LPCIM depends on the specific requirements of the application, including mechanical properties, thermal stability, electrical conductivity, and biocompatibility. The versatility of LPCIM in accommodating a wide range of materials allows manufacturers to produce components that meet the stringent demands of various industries. This flexibility, combined with the precision and efficiency of the low-pressure injection molding process, makes LPCIM a preferred method for producing high-performance ceramic parts.

Electrical Components, Semiconductor Insulators, Medical Instrumentation, Aerospace Igniters, Agricultural Wear Components, Others in the Global Low Pressure Ceramic Injection Molding Market:

The Global Low Pressure Ceramic Injection Molding Market finds extensive usage across various sectors, including electrical components, semiconductor insulators, medical instrumentation, aerospace igniters, agricultural wear components, and others. In the field of electrical components, LPCIM is used to manufacture high-precision insulators, connectors, and substrates that require excellent electrical insulation, thermal stability, and mechanical strength. These components are essential in ensuring the reliability and performance of electronic devices and systems. In semiconductor insulators, LPCIM produces parts that provide critical insulation and protection for semiconductor devices, ensuring their proper functioning and longevity. The medical instrumentation sector benefits from LPCIM through the production of biocompatible and high-strength components such as surgical tools, dental implants, and diagnostic equipment. These ceramic parts offer superior wear resistance, chemical stability, and compatibility with the human body, making them ideal for medical applications. Aerospace igniters and other components made using LPCIM are designed to withstand extreme temperatures, mechanical stress, and corrosive environments, ensuring the safety and efficiency of aerospace systems. In agriculture, LPCIM is used to produce wear-resistant components such as nozzles, bearings, and cutting tools that can endure harsh operating conditions and extend the lifespan of agricultural machinery. Other applications of LPCIM include the production of high-performance parts for automotive, defense, and industrial sectors, where the demand for durable, precise, and reliable ceramic components is high. The versatility and precision of LPCIM make it a valuable technology for manufacturing complex and high-quality ceramic parts across these diverse industries.

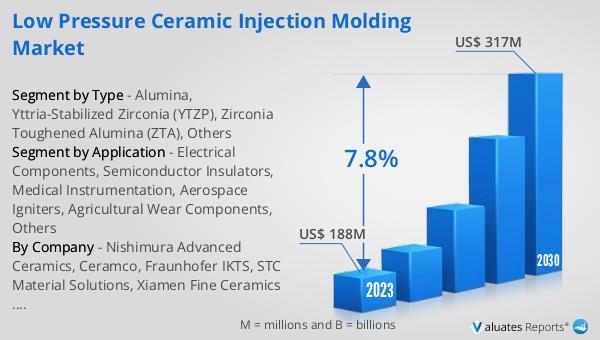

Global Low Pressure Ceramic Injection Molding Market Outlook:

The global Low Pressure Ceramic Injection Molding market was valued at US$ 188 million in 2023 and is anticipated to reach US$ 317 million by 2030, witnessing a CAGR of 7.8% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-precision and high-performance ceramic components across various industries. The LPCIM market's expansion is driven by advancements in technology, the growing need for miniaturization in electronic devices, and the rising adoption of ceramics in medical and aerospace applications. The ability of LPCIM to produce complex shapes with excellent material properties makes it an attractive solution for manufacturers looking to enhance the performance and reliability of their products. As industries continue to seek innovative materials and manufacturing processes, the LPCIM market is poised to play a crucial role in meeting these evolving demands.

| Report Metric | Details |

| Report Name | Low Pressure Ceramic Injection Molding Market |

| Accounted market size in 2023 | US$ 188 million |

| Forecasted market size in 2030 | US$ 317 million |

| CAGR | 7.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nishimura Advanced Ceramics, Ceramco, Fraunhofer IKTS, STC Material Solutions, Xiamen Fine Ceramics Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |