What is Global Lead-free Solder Market?

The Global Lead-free Solder Market refers to the industry focused on the production and distribution of solder materials that do not contain lead. Solder is a fusible metal alloy used to join together metal workpieces and has traditionally contained lead due to its low melting point and ease of use. However, due to health and environmental concerns, there has been a significant shift towards lead-free alternatives. These lead-free solders are primarily composed of tin, along with other metals such as silver, copper, and bismuth. The market for these materials is growing as regulations and consumer preferences increasingly favor environmentally friendly and safer products. The global lead-free solder market encompasses various forms of solder, including solder bars, solder wires, solder pastes, and solder balls, each tailored for specific applications in industries such as electronics, automotive, aerospace, and medical devices. The transition to lead-free solder is driven by stringent regulations like the Restriction of Hazardous Substances (RoHS) directive in the European Union, which mandates the reduction of hazardous materials in electronic products. This market is crucial for ensuring the sustainability and safety of electronic manufacturing processes worldwide.

Solder Bar, Solder Wire, Solder Paste, Solder Ball in the Global Lead-free Solder Market:

Solder bars, solder wires, solder pastes, and solder balls are essential components of the global lead-free solder market, each serving unique purposes in various applications. Solder bars are typically used in wave soldering processes, where they are melted in a solder pot and used to create solder joints on printed circuit boards (PCBs). These bars are favored for their ease of use and ability to produce consistent, high-quality joints. Solder wires, on the other hand, are used in manual soldering and rework tasks. They are available in different diameters and flux core types, making them versatile for a range of applications from small-scale electronics repair to large-scale manufacturing. Solder paste is a mixture of powdered solder and flux, used primarily in surface mount technology (SMT) for attaching components to PCBs. The paste is applied using a stencil and then heated to create strong, reliable solder joints. Solder balls are small, spherical solder particles used in ball grid array (BGA) packaging, a type of surface-mount packaging used for integrated circuits. These balls provide electrical connections between the chip and the PCB, ensuring reliable performance in high-density electronic assemblies. Each of these solder forms plays a critical role in the manufacturing and repair of electronic devices, contributing to the overall efficiency and reliability of the production process. The shift to lead-free versions of these solders is driven by the need to comply with environmental regulations and to reduce the health risks associated with lead exposure. As a result, manufacturers are continually developing and refining lead-free solder formulations to meet the demands of modern electronics manufacturing.

Automotive, Computing / Servers, Handheld, Aerospace, Appliances, Medical, Photovoltaic in the Global Lead-free Solder Market:

The usage of lead-free solder in various industries highlights its importance and versatility. In the automotive industry, lead-free solder is used extensively in the manufacturing of electronic control units (ECUs), sensors, and other electronic components that are critical for vehicle performance and safety. The reliability and durability of lead-free solder joints are essential for the harsh operating conditions in automotive applications. In the computing and server industry, lead-free solder is used in the assembly of motherboards, processors, and other critical components. The high thermal and mechanical reliability of lead-free solder ensures the longevity and performance of computing devices. Handheld devices, such as smartphones and tablets, also rely on lead-free solder for the assembly of their compact and intricate electronic circuits. The miniaturization of components in these devices requires precise and reliable soldering techniques, which lead-free solder provides. In the aerospace industry, lead-free solder is used in the manufacturing of avionics and other electronic systems that require high reliability and performance in extreme conditions. The use of lead-free solder in appliances, such as refrigerators, washing machines, and microwaves, ensures the safety and durability of these household devices. In the medical industry, lead-free solder is used in the assembly of medical devices and equipment, where the safety and reliability of solder joints are critical for patient care. The photovoltaic industry also benefits from lead-free solder in the manufacturing of solar panels, where it is used to create reliable electrical connections between solar cells. The use of lead-free solder in these diverse industries underscores its importance in modern manufacturing and its role in promoting environmental sustainability and safety.

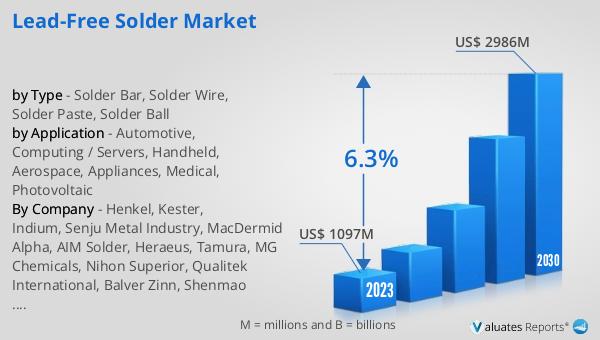

Global Lead-free Solder Market Outlook:

The global lead-free solder market was valued at approximately $1,097 million in 2023 and is projected to reach around $2,986 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. This significant growth is driven by increasing regulatory pressures and consumer demand for environmentally friendly and safer products. The transition from traditional lead-based solders to lead-free alternatives is not just a regulatory compliance measure but also a proactive step towards sustainable manufacturing practices. The market's expansion is supported by advancements in lead-free solder formulations that offer improved performance characteristics, such as higher thermal and mechanical reliability, which are essential for modern electronic devices. As industries such as automotive, computing, aerospace, and medical devices continue to evolve and demand more sophisticated and reliable electronic components, the need for high-quality lead-free solder will only increase. This growth trajectory highlights the critical role of lead-free solder in the future of electronic manufacturing, ensuring that products are not only high-performing but also safe for both users and the environment. The market outlook underscores the importance of continued innovation and development in lead-free solder technologies to meet the ever-growing demands of various industries.

| Report Metric | Details |

| Report Name | Lead-free Solder Market |

| Accounted market size in 2023 | US$ 1097 million |

| Forecasted market size in 2030 | US$ 2986 million |

| CAGR | 6.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Henkel, Kester, Indium, Senju Metal Industry, MacDermid Alpha, AIM Solder, Heraeus, Tamura, MG Chemicals, Nihon Superior, Qualitek International, Balver Zinn, Shenmao Technology, Fitech, Guangzhou Xianyi Electronic Technology, ChongQing Qunwin Electronic Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |