What is Global Dry Offset Printing Market?

The Global Dry Offset Printing Market is a specialized segment within the broader printing industry that focuses on a unique printing technique known as dry offset printing. This method combines elements of both letterpress and offset printing, making it highly efficient for producing high-quality images and text on various substrates. Unlike traditional offset printing, dry offset printing does not use water in the process, which allows for faster drying times and reduces the risk of smudging. This technique is particularly popular for printing on non-porous surfaces such as metal, plastic, and other materials that are commonly used in packaging. The market for dry offset printing is driven by its applications in industries like food and beverage, cosmetics, pharmaceuticals, and daily necessities, where high-quality, durable, and visually appealing packaging is essential. The global demand for dry offset printing is growing as manufacturers seek more efficient and cost-effective ways to produce packaging that stands out on the shelves. The versatility and efficiency of dry offset printing make it a valuable tool for businesses looking to enhance their product presentation and brand image.

Thickness Below 0.5 mm, Thickness 0.5-1 mm, Thickness Above 1 mm in the Global Dry Offset Printing Market:

In the Global Dry Offset Printing Market, the thickness of the substrate plays a crucial role in determining the printing process and the quality of the final product. Substrates with a thickness below 0.5 mm are typically used for applications that require flexibility and lightweight materials. These thin substrates are ideal for printing on items like labels, flexible packaging, and thin plastic containers. The dry offset printing process ensures that even with such thin materials, the print quality remains high, with sharp images and vibrant colors. On the other hand, substrates with a thickness ranging from 0.5 mm to 1 mm are commonly used for more rigid packaging solutions. This thickness range is suitable for products like beverage cans, food containers, and cosmetic packaging. The dry offset printing technique allows for precise and consistent printing on these slightly thicker materials, ensuring that the packaging is both attractive and durable. For substrates with a thickness above 1 mm, the applications are typically more specialized. These thicker materials are often used for industrial packaging, promotional items, and other products that require a sturdy and robust packaging solution. The dry offset printing process is well-suited for these applications as it can handle the increased thickness without compromising on print quality. The ability to print on a wide range of substrate thicknesses makes dry offset printing a versatile and valuable technique in the packaging industry. It allows manufacturers to choose the appropriate material thickness based on the specific requirements of their products, ensuring that the packaging not only looks good but also provides the necessary protection and durability.

Beverage, Food, Daily Necessity, Cosmetics, Pharmaceutical, Others in the Global Dry Offset Printing Market:

The Global Dry Offset Printing Market finds extensive usage across various sectors, including beverages, food, daily necessities, cosmetics, pharmaceuticals, and others. In the beverage industry, dry offset printing is commonly used for printing on cans and bottles. The technique ensures that the labels are vibrant, durable, and resistant to moisture, making it ideal for products that are often stored in cool and damp environments. In the food industry, dry offset printing is used for packaging materials such as plastic containers, lids, and flexible packaging. The high-quality print ensures that the packaging is visually appealing and can withstand the rigors of transportation and storage. For daily necessities, dry offset printing is used for a wide range of products, including household cleaning products, personal care items, and other everyday goods. The technique allows for high-quality printing on various materials, ensuring that the packaging is both attractive and functional. In the cosmetics industry, dry offset printing is used for packaging products such as tubes, jars, and bottles. The technique ensures that the packaging is visually appealing and can withstand exposure to various environmental factors, such as moisture and temperature changes. In the pharmaceutical industry, dry offset printing is used for packaging materials such as blister packs, bottles, and tubes. The technique ensures that the packaging is durable and can protect the contents from contamination and damage. Other industries that use dry offset printing include automotive, electronics, and promotional products. The versatility and efficiency of dry offset printing make it a valuable tool for businesses across various sectors, allowing them to produce high-quality packaging that enhances their product presentation and brand image.

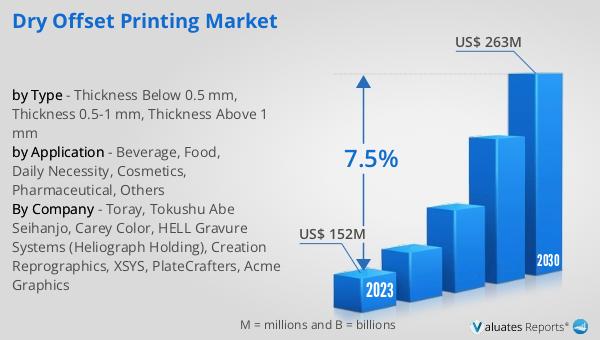

Global Dry Offset Printing Market Outlook:

The global Dry Offset Printing market was valued at US$ 152 million in 2023 and is anticipated to reach US$ 263 million by 2030, witnessing a CAGR of 7.5% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for high-quality, durable, and visually appealing packaging solutions across various industries. The dry offset printing technique, known for its efficiency and ability to produce sharp images and vibrant colors, is becoming increasingly popular among manufacturers. The market's expansion is driven by the need for cost-effective and efficient printing solutions that can handle a wide range of substrates and thicknesses. As businesses continue to seek ways to enhance their product presentation and brand image, the demand for dry offset printing is expected to grow. The versatility of this printing technique makes it suitable for a wide range of applications, from beverage cans and food containers to cosmetic packaging and pharmaceutical products. The projected growth of the global Dry Offset Printing market underscores the importance of this technique in the modern packaging industry, highlighting its role in meeting the evolving needs of manufacturers and consumers alike.

| Report Metric | Details |

| Report Name | Dry Offset Printing Market |

| Accounted market size in 2023 | US$ 152 million |

| Forecasted market size in 2030 | US$ 263 million |

| CAGR | 7.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray, Tokushu Abe Seihanjo, Carey Color, HELL Gravure Systems (Heliograph Holding), Creation Reprographics, XSYS, PlateCrafters, Acme Graphics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |