What is Global Electric Vehicle Solid Copper Busbar Market?

The Global Electric Vehicle Solid Copper Busbar Market refers to the industry focused on the production and distribution of solid copper busbars specifically designed for electric vehicles (EVs). These busbars are essential components in EVs, serving as conductors that efficiently transmit electrical power between the battery, motor, and other electrical systems within the vehicle. The market encompasses various types of copper busbars, including Electrolytic Tough Pitch (ETP) copper busbars, Oxygen-Free (OF) copper busbars, and others, each offering distinct advantages in terms of conductivity, durability, and resistance to oxidation. As the demand for electric vehicles continues to rise globally, driven by the need for sustainable and eco-friendly transportation solutions, the market for solid copper busbars is also experiencing significant growth. This growth is fueled by advancements in EV technology, increasing government regulations promoting electric mobility, and the ongoing efforts of manufacturers to enhance the efficiency and performance of electric vehicles.

ETP (Electrolytic Tough Pitch Copper Busbar), OF (Oxygen-free Copper Busbar), Others in the Global Electric Vehicle Solid Copper Busbar Market:

ETP (Electrolytic Tough Pitch) copper busbars are a popular choice in the Global Electric Vehicle Solid Copper Busbar Market due to their excellent electrical conductivity and cost-effectiveness. ETP copper is produced through an electrolytic refining process, which results in a high-purity copper with a minimum copper content of 99.9%. This high purity ensures that ETP copper busbars have low electrical resistance, making them highly efficient in conducting electricity. Additionally, ETP copper busbars are known for their good mechanical properties, including high tensile strength and ductility, which make them suitable for various applications in electric vehicles. However, one of the limitations of ETP copper is its susceptibility to oxidation, which can affect its long-term performance in certain environments. On the other hand, Oxygen-Free (OF) copper busbars are manufactured through a process that eliminates oxygen and other impurities, resulting in a copper with even higher purity levels than ETP copper. The absence of oxygen in OF copper busbars significantly enhances their electrical conductivity and resistance to oxidation, making them ideal for use in critical applications where reliability and performance are paramount. OF copper busbars are particularly favored in high-performance electric vehicles and applications that require superior thermal and electrical conductivity. Despite their higher cost compared to ETP copper busbars, the benefits of OF copper in terms of longevity and efficiency often justify the investment for many manufacturers. In addition to ETP and OF copper busbars, the Global Electric Vehicle Solid Copper Busbar Market also includes other types of copper busbars, such as high-conductivity copper alloys and custom-designed busbars tailored to specific requirements. These busbars are engineered to meet the unique demands of different electric vehicle models and applications, offering a balance between performance, cost, and durability. For instance, high-conductivity copper alloys may be used in applications where both electrical and mechanical properties need to be optimized, providing a versatile solution for various EV components. Custom-designed busbars, on the other hand, are developed in collaboration with EV manufacturers to address specific design challenges and enhance the overall efficiency and performance of the vehicle's electrical system. The choice of copper busbar type in the Global Electric Vehicle Solid Copper Busbar Market ultimately depends on factors such as the specific requirements of the electric vehicle, the desired balance between cost and performance, and the operating environment. As the market continues to evolve, ongoing research and development efforts are focused on improving the properties of copper busbars, exploring new materials and manufacturing techniques, and enhancing the overall efficiency and reliability of electric vehicles. These advancements are expected to drive further growth in the market, as manufacturers strive to meet the increasing demand for high-performance, sustainable, and cost-effective solutions in the electric vehicle industry.

BEV, PHEV in the Global Electric Vehicle Solid Copper Busbar Market:

The usage of Global Electric Vehicle Solid Copper Busbar Market in Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs) is crucial for the efficient operation of these vehicles. In BEVs, which rely solely on electric power for propulsion, solid copper busbars play a vital role in connecting the battery pack to the electric motor and other electrical components. The high conductivity of copper ensures minimal energy loss during power transmission, which is essential for maximizing the range and performance of BEVs. Additionally, the durability and reliability of copper busbars contribute to the overall longevity and safety of the vehicle's electrical system. As BEVs continue to gain popularity due to their zero-emission nature and lower operating costs, the demand for high-quality copper busbars is expected to rise, driving further advancements in the market. In PHEVs, which combine an internal combustion engine with an electric motor and battery, solid copper busbars are equally important. These vehicles can operate in both electric-only mode and hybrid mode, depending on the driving conditions and battery charge level. The copper busbars facilitate the seamless transfer of electrical power between the battery, electric motor, and other components, ensuring optimal performance and efficiency in both modes. The ability of copper busbars to handle high current loads and resist thermal stress is particularly beneficial in PHEVs, where the electrical system must accommodate the varying power demands of both the electric motor and the internal combustion engine. This versatility makes copper busbars an indispensable component in the design and operation of PHEVs. Moreover, the use of solid copper busbars in BEVs and PHEVs extends beyond the primary powertrain components. These busbars are also employed in various auxiliary systems, such as charging infrastructure, power distribution units, and thermal management systems. In charging infrastructure, copper busbars are used to connect the vehicle's battery to the charging station, ensuring efficient and safe power transfer during the charging process. In power distribution units, copper busbars help manage the distribution of electrical power to different subsystems within the vehicle, such as lighting, infotainment, and climate control. In thermal management systems, copper busbars assist in maintaining optimal operating temperatures for the battery and other critical components, enhancing the overall efficiency and reliability of the vehicle. The growing adoption of BEVs and PHEVs is driving the demand for advanced copper busbar solutions that can meet the evolving needs of the electric vehicle industry. Manufacturers are continuously exploring new materials, designs, and manufacturing techniques to enhance the performance, efficiency, and cost-effectiveness of copper busbars. For instance, innovations in busbar design, such as laminated busbars and flexible busbars, are being developed to improve electrical performance, reduce weight, and simplify installation. Additionally, advancements in copper alloy formulations are being pursued to enhance the mechanical and thermal properties of busbars, making them more suitable for the demanding conditions of electric vehicle applications. In conclusion, the usage of Global Electric Vehicle Solid Copper Busbar Market in BEVs and PHEVs is integral to the efficient and reliable operation of these vehicles. The high conductivity, durability, and versatility of copper busbars make them an essential component in the powertrain and auxiliary systems of electric vehicles. As the market for BEVs and PHEVs continues to expand, driven by the increasing demand for sustainable and eco-friendly transportation solutions, the need for high-quality copper busbars is expected to grow, fostering further innovation and development in the market.

Global Electric Vehicle Solid Copper Busbar Market Outlook:

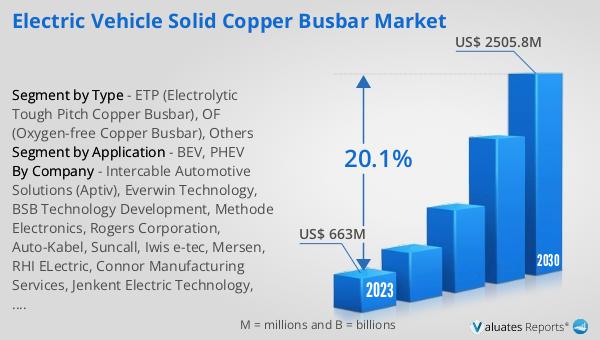

The global Electric Vehicle Solid Copper Busbar market was valued at US$ 663 million in 2023 and is anticipated to reach US$ 2505.8 million by 2030, witnessing a CAGR of 20.1% during the forecast period 2024-2030. This significant growth reflects the increasing demand for electric vehicles and the essential role that solid copper busbars play in their efficient operation. As electric vehicles become more prevalent, the need for reliable and high-performance electrical components, such as copper busbars, is becoming increasingly critical. The projected growth in the market underscores the importance of continuous innovation and development in copper busbar technology to meet the evolving needs of the electric vehicle industry.

| Report Metric | Details |

| Report Name | Electric Vehicle Solid Copper Busbar Market |

| Accounted market size in 2023 | US$ 663 million |

| Forecasted market size in 2030 | US$ 2505.8 million |

| CAGR | 20.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Intercable Automotive Solutions (Aptiv), Everwin Technology, BSB Technology Development, Methode Electronics, Rogers Corporation, Auto-Kabel, Suncall, Iwis e-tec, Mersen, RHI ELectric, Connor Manufacturing Services, Jenkent Electric Technology, Interplex, Crefact |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |