What is Global Bended Copper Busbar for Electric Vehicle Market?

The Global Bended Copper Busbar for Electric Vehicle Market refers to the specialized market segment that focuses on the production and distribution of bended copper busbars specifically designed for electric vehicles (EVs). Copper busbars are critical components in EVs as they facilitate the efficient transmission of electrical power within the vehicle's electrical system. These busbars are made from high-conductivity copper, which ensures minimal energy loss and optimal performance. The "bended" aspect refers to the custom shapes and configurations that these busbars can be manufactured into, allowing them to fit seamlessly into the compact and complex layouts of modern electric vehicles. This market is driven by the increasing adoption of electric vehicles globally, as well as advancements in EV technology that demand more efficient and reliable electrical components. The growth of this market is also supported by the rising awareness of environmental issues and the push for cleaner, more sustainable transportation solutions. As a result, manufacturers are investing in research and development to produce high-quality bended copper busbars that meet the stringent requirements of the EV industry.

ETP (Electrolytic Tough Pitch Copper Busbar), OF (Oxygen-free Copper Busbar), Others in the Global Bended Copper Busbar for Electric Vehicle Market:

ETP (Electrolytic Tough Pitch) Copper Busbar, OF (Oxygen-Free) Copper Busbar, and other types of copper busbars play significant roles in the Global Bended Copper Busbar for Electric Vehicle Market. ETP copper busbars are made from high-purity copper and are known for their excellent electrical conductivity and thermal performance. They are produced through an electrolytic refining process that ensures a high level of purity, typically around 99.9% copper content. This makes them ideal for use in electric vehicles, where efficient power transmission is crucial. ETP copper busbars are also relatively cost-effective, making them a popular choice among manufacturers. On the other hand, OF copper busbars are produced in an oxygen-free environment, which results in even higher purity levels, often exceeding 99.99% copper content. The absence of oxygen in the production process eliminates the risk of oxidation, which can degrade the performance of the busbars over time. This makes OF copper busbars highly reliable and durable, suitable for high-performance and high-reliability applications in electric vehicles. Other types of copper busbars used in the EV market include high-conductivity copper alloys and custom-engineered busbars designed to meet specific performance requirements. These busbars may incorporate additional elements such as silver or tin to enhance their properties, such as corrosion resistance or mechanical strength. The choice of busbar type depends on various factors, including the specific requirements of the EV's electrical system, cost considerations, and the desired balance between performance and durability. Overall, the diversity of copper busbar types available in the market allows manufacturers to select the most appropriate solution for their specific needs, ensuring optimal performance and reliability of their electric vehicles.

BEV, PHEV in the Global Bended Copper Busbar for Electric Vehicle Market:

The usage of Global Bended Copper Busbar for Electric Vehicle Market in Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs) is crucial for the efficient operation of these vehicles. In BEVs, which rely entirely on electric power, bended copper busbars are used to connect various electrical components, including the battery pack, power inverter, and electric motor. These busbars ensure that electrical power is transmitted efficiently with minimal energy loss, which is essential for maximizing the vehicle's range and performance. The custom shapes and configurations of bended copper busbars allow them to fit seamlessly into the compact and complex layouts of BEVs, ensuring optimal space utilization and ease of assembly. In PHEVs, which combine an internal combustion engine with an electric powertrain, bended copper busbars play a similar role in connecting the electrical components of the vehicle. However, the presence of both an electric motor and an internal combustion engine in PHEVs adds complexity to the electrical system, making the use of high-quality, reliable busbars even more critical. Bended copper busbars in PHEVs help to ensure efficient power transmission between the battery pack, electric motor, and other electrical components, enabling smooth and seamless operation of the vehicle in both electric and hybrid modes. Additionally, the use of bended copper busbars in both BEVs and PHEVs contributes to the overall safety and reliability of the vehicles. Copper's excellent electrical conductivity and thermal performance help to minimize the risk of overheating and electrical faults, which can be critical in high-power applications such as electric vehicles. Furthermore, the durability and corrosion resistance of copper busbars ensure long-term reliability and performance, reducing the need for frequent maintenance and replacement. Overall, the use of Global Bended Copper Busbar for Electric Vehicle Market in BEVs and PHEVs is essential for ensuring efficient, reliable, and safe operation of these vehicles, supporting the continued growth and adoption of electric mobility solutions.

Global Bended Copper Busbar for Electric Vehicle Market Outlook:

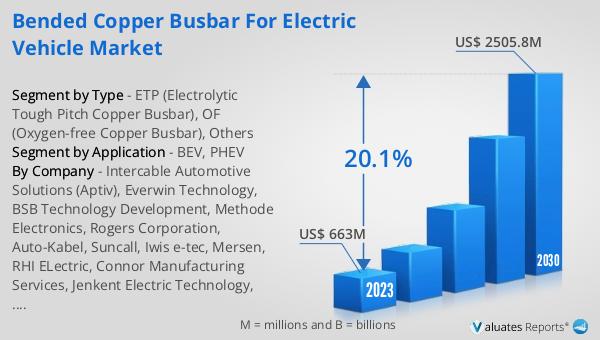

The global Bended Copper Busbar for Electric Vehicle market was valued at US$ 663 million in 2023 and is anticipated to reach US$ 2505.8 million by 2030, witnessing a CAGR of 20.1% during the forecast period 2024-2030. This significant growth reflects the increasing demand for electric vehicles and the critical role that bended copper busbars play in their electrical systems. As electric vehicles become more prevalent, the need for efficient and reliable electrical components, such as bended copper busbars, continues to rise. These busbars are essential for ensuring optimal power transmission within the vehicle, contributing to improved performance, range, and overall reliability. The projected growth of the market also highlights the ongoing advancements in EV technology and the continuous efforts of manufacturers to develop high-quality, innovative solutions that meet the evolving needs of the industry. With the global push towards cleaner and more sustainable transportation options, the demand for bended copper busbars is expected to remain strong, driving further growth and development in this market segment.

| Report Metric | Details |

| Report Name | Bended Copper Busbar for Electric Vehicle Market |

| Accounted market size in 2023 | US$ 663 million |

| Forecasted market size in 2030 | US$ 2505.8 million |

| CAGR | 20.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Intercable Automotive Solutions (Aptiv), Everwin Technology, BSB Technology Development, Methode Electronics, Rogers Corporation, Auto-Kabel, Suncall, Iwis e-tec, Mersen, RHI ELectric, Connor Manufacturing Services, Jenkent Electric Technology, Interplex, Crefact |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |