What is Global Copper Braided Busbar Market?

The Global Copper Braided Busbar Market refers to the worldwide industry focused on the production, distribution, and utilization of copper braided busbars. These busbars are essential components in electrical systems, providing a flexible and efficient means of conducting electricity. Made from high-quality copper strands woven together, they offer superior conductivity and durability compared to traditional solid busbars. The market encompasses various applications, including power distribution, grounding, and bonding in industries such as power generation, automotive, aerospace, and telecommunications. The demand for copper braided busbars is driven by their ability to handle high current loads, resist corrosion, and provide reliable electrical connections in both static and dynamic environments. As industries continue to modernize and seek more efficient electrical solutions, the global copper braided busbar market is expected to grow, driven by advancements in technology and increasing demand for energy-efficient systems.

Electrolytic Tin Plating, Electrolytic Silver Plating, Others in the Global Copper Braided Busbar Market:

Electrolytic tin plating, electrolytic silver plating, and other types of plating are crucial processes in the global copper braided busbar market. Electrolytic tin plating involves coating the copper busbars with a thin layer of tin through an electrochemical process. This tin layer enhances the busbar's resistance to corrosion and oxidation, ensuring long-term reliability and performance. Tin-plated copper busbars are widely used in environments where exposure to moisture and chemicals is a concern, such as in marine and industrial applications. On the other hand, electrolytic silver plating involves depositing a layer of silver onto the copper busbars. Silver is known for its excellent electrical conductivity and thermal properties, making silver-plated busbars ideal for high-frequency and high-temperature applications. These busbars are commonly used in aerospace, military, and high-performance electronic systems where superior conductivity and thermal management are critical. Other types of plating, such as nickel or gold, may also be used depending on the specific requirements of the application. Nickel plating provides additional corrosion resistance and hardness, making it suitable for harsh environments. Gold plating, although more expensive, offers exceptional conductivity and resistance to tarnish, making it ideal for precision electronic components. The choice of plating material depends on factors such as the operating environment, electrical and thermal requirements, and cost considerations. Each type of plating offers unique benefits, and the selection process involves balancing performance, durability, and cost to meet the specific needs of the application. As the global copper braided busbar market continues to evolve, advancements in plating technologies and materials are expected to further enhance the performance and reliability of these critical electrical components.

Power, Military, Aerospace and Aviation, Others in the Global Copper Braided Busbar Market:

The global copper braided busbar market finds extensive usage across various sectors, including power, military, aerospace and aviation, and others. In the power sector, copper braided busbars are essential for efficient power distribution and grounding. They are used in substations, switchgear, transformers, and other electrical equipment to ensure reliable and efficient power transmission. The flexibility of braided busbars allows for easy installation and maintenance, making them a preferred choice in power generation and distribution systems. In the military sector, copper braided busbars are used in various applications, including communication systems, radar equipment, and weapon systems. Their ability to handle high current loads and resist harsh environmental conditions makes them ideal for military applications where reliability and performance are critical. In the aerospace and aviation industry, copper braided busbars are used in aircraft electrical systems, including power distribution, grounding, and bonding. They provide reliable electrical connections in the dynamic and high-vibration environment of aircraft, ensuring the safety and efficiency of the electrical systems. Other sectors, such as automotive, telecommunications, and industrial machinery, also utilize copper braided busbars for their superior conductivity, flexibility, and durability. In the automotive industry, they are used in electric vehicles and hybrid vehicles for efficient power distribution and grounding. In telecommunications, they are used in base stations, data centers, and other communication infrastructure to ensure reliable and efficient electrical connections. In industrial machinery, copper braided busbars are used in various equipment and machinery to provide reliable power distribution and grounding. The versatility and performance of copper braided busbars make them a critical component in a wide range of applications, driving their demand across various industries.

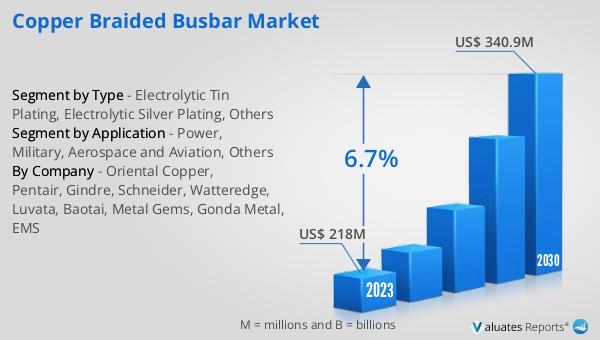

Global Copper Braided Busbar Market Outlook:

The global copper braided busbar market was valued at $218 million in 2023 and is projected to reach $340.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.7% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for efficient and reliable electrical systems across various industries. The superior conductivity, flexibility, and durability of copper braided busbars make them a preferred choice for power distribution, grounding, and bonding applications. As industries continue to modernize and seek more energy-efficient solutions, the demand for copper braided busbars is expected to rise. Advancements in technology and materials are also contributing to the growth of the market, enhancing the performance and reliability of these critical electrical components. The market outlook indicates a positive trend, with significant growth opportunities in various sectors, including power, military, aerospace, automotive, telecommunications, and industrial machinery. The increasing adoption of electric vehicles, renewable energy systems, and advanced communication infrastructure is expected to further drive the demand for copper braided busbars. As the market continues to evolve, manufacturers are focusing on developing innovative products and solutions to meet the specific needs of different applications, ensuring the continued growth and success of the global copper braided busbar market.

| Report Metric | Details |

| Report Name | Copper Braided Busbar Market |

| Accounted market size in 2023 | US$ 218 million |

| Forecasted market size in 2030 | US$ 340.9 million |

| CAGR | 6.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Oriental Copper, Pentair, Gindre, Schneider, Watteredge, Luvata, Baotai, Metal Gems, Gonda Metal, EMS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |