What is Global Aluminum Busbar for Electric Vehicle Market?

The Global Aluminum Busbar for Electric Vehicle Market refers to the industry focused on the production and distribution of aluminum busbars specifically designed for electric vehicles (EVs). Aluminum busbars are essential components in EVs, serving as conductors that efficiently transmit electrical power between the battery, motor, and other electrical systems. These busbars are preferred over traditional copper busbars due to their lightweight nature, cost-effectiveness, and excellent electrical conductivity. The increasing demand for electric vehicles, driven by the global push towards sustainable transportation and stringent emission regulations, has significantly boosted the market for aluminum busbars. As more automakers transition to electric vehicle production, the need for reliable and efficient electrical components like aluminum busbars continues to grow. This market encompasses various stakeholders, including raw material suppliers, manufacturers, and end-users, all working together to meet the evolving needs of the electric vehicle industry.

Nickel Plating, Silver Plating, Tin Plating in the Global Aluminum Busbar for Electric Vehicle Market:

Nickel plating, silver plating, and tin plating are three common surface treatments applied to aluminum busbars in the Global Aluminum Busbar for Electric Vehicle Market. Each of these plating methods offers unique benefits that enhance the performance and durability of aluminum busbars in electric vehicles. Nickel plating involves coating the aluminum busbar with a thin layer of nickel, which provides excellent corrosion resistance, increased hardness, and improved wear resistance. This makes nickel-plated busbars ideal for use in harsh environments where they are exposed to moisture, chemicals, and high temperatures. Silver plating, on the other hand, is known for its superior electrical conductivity and low contact resistance. By applying a layer of silver to the aluminum busbar, manufacturers can ensure efficient power transmission and minimal energy loss, which is crucial for the performance of electric vehicles. Silver-plated busbars are particularly beneficial in high-current applications where maintaining low resistance is essential. Tin plating is another popular surface treatment for aluminum busbars, offering good corrosion resistance and solderability. Tin-plated busbars are often used in applications where reliable electrical connections are required, as the tin coating facilitates easy soldering and ensures strong, durable joints. Additionally, tin plating provides a cost-effective solution for protecting aluminum busbars from oxidation and other environmental factors. In summary, nickel plating, silver plating, and tin plating each contribute to the overall performance and longevity of aluminum busbars in electric vehicles, addressing specific needs such as corrosion resistance, electrical conductivity, and solderability. By selecting the appropriate plating method, manufacturers can optimize the functionality and reliability of aluminum busbars, ultimately enhancing the efficiency and performance of electric vehicles.

BEV, PHEV in the Global Aluminum Busbar for Electric Vehicle Market:

The usage of Global Aluminum Busbar for Electric Vehicle Market in Battery Electric Vehicles (BEVs) and Plug-in Hybrid Electric Vehicles (PHEVs) is crucial for their efficient operation. In BEVs, aluminum busbars play a vital role in connecting the battery pack to the electric motor and other electrical components. The lightweight nature of aluminum helps reduce the overall weight of the vehicle, which is essential for maximizing the driving range and improving energy efficiency. Additionally, aluminum busbars offer excellent electrical conductivity, ensuring efficient power transmission from the battery to the motor, which is critical for the performance of BEVs. The use of aluminum busbars also contributes to the thermal management of the battery pack, as they can effectively dissipate heat generated during high-power operations, thereby enhancing the safety and longevity of the battery. In PHEVs, aluminum busbars are equally important, as they facilitate the seamless integration of the internal combustion engine and the electric motor. The busbars connect the battery to the electric motor, enabling the vehicle to switch between electric and hybrid modes efficiently. The lightweight and cost-effective nature of aluminum busbars make them an ideal choice for PHEVs, as they help reduce the overall vehicle weight and manufacturing costs. Furthermore, the excellent electrical conductivity of aluminum ensures efficient power transfer, which is essential for the optimal performance of both the electric and hybrid systems in PHEVs. The use of aluminum busbars in PHEVs also aids in thermal management, as they help dissipate heat generated during high-power operations, ensuring the safety and reliability of the vehicle's electrical system. Overall, the application of aluminum busbars in BEVs and PHEVs is critical for enhancing their performance, efficiency, and safety, making them an indispensable component in the electric vehicle industry.

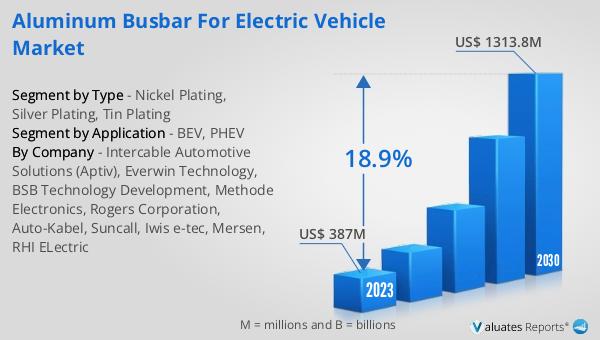

Global Aluminum Busbar for Electric Vehicle Market Outlook:

The global Aluminum Busbar for Electric Vehicle market was valued at US$ 387 million in 2023 and is anticipated to reach US$ 1313.8 million by 2030, witnessing a CAGR of 18.9% during the forecast period 2024-2030. This significant growth reflects the increasing demand for electric vehicles and the essential role that aluminum busbars play in their electrical systems. As the market continues to expand, manufacturers are focusing on developing advanced aluminum busbars that offer improved performance, durability, and cost-effectiveness. The rising adoption of electric vehicles, driven by environmental concerns and government regulations, is a key factor contributing to the market's growth. Additionally, advancements in battery technology and the increasing availability of charging infrastructure are further propelling the demand for aluminum busbars. The market's robust growth trajectory underscores the importance of aluminum busbars in the electric vehicle industry and highlights the ongoing efforts to enhance their efficiency and reliability.

| Report Metric | Details |

| Report Name | Aluminum Busbar for Electric Vehicle Market |

| Accounted market size in 2023 | US$ 387 million |

| Forecasted market size in 2030 | US$ 1313.8 million |

| CAGR | 18.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Intercable Automotive Solutions (Aptiv), Everwin Technology, BSB Technology Development, Methode Electronics, Rogers Corporation, Auto-Kabel, Suncall, Iwis e-tec, Mersen, RHI ELectric |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |