What is Global Ceramic Heat Sink Substrate Market?

The Global Ceramic Heat Sink Substrate Market refers to the worldwide industry focused on the production and distribution of ceramic substrates used in heat sinks. These substrates are essential components in various electronic devices, helping to dissipate heat and maintain optimal operating temperatures. Ceramic materials are chosen for their excellent thermal conductivity, electrical insulation properties, and durability. The market encompasses a range of ceramic materials, including alumina, silicon nitride, silicon carbide, and zirconia, each offering unique benefits for specific applications. The demand for ceramic heat sink substrates is driven by the increasing need for efficient thermal management solutions in high-performance electronics, automotive systems, industrial machinery, and other sectors. As technology advances and electronic devices become more powerful, the importance of effective heat dissipation continues to grow, making the Global Ceramic Heat Sink Substrate Market a critical component of the broader electronics and materials industries.

Alumina, Silicon Nitride, Silicon Carbide, Zirconia, Others in the Global Ceramic Heat Sink Substrate Market:

Alumina, silicon nitride, silicon carbide, zirconia, and other materials play pivotal roles in the Global Ceramic Heat Sink Substrate Market, each offering distinct advantages for various applications. Alumina, or aluminum oxide, is one of the most commonly used ceramic materials due to its excellent thermal conductivity, electrical insulation, and cost-effectiveness. It is widely used in electronic packaging and heat sinks for consumer electronics, automotive electronics, and industrial applications. Silicon nitride, known for its high thermal conductivity and mechanical strength, is often used in high-performance applications where durability and reliability are critical, such as in aerospace and advanced automotive systems. Silicon carbide, with its exceptional thermal conductivity and ability to withstand high temperatures, is ideal for power electronics and high-frequency applications. It is also used in harsh environments where other materials might fail. Zirconia, or zirconium dioxide, is valued for its high fracture toughness and thermal stability, making it suitable for applications requiring robust mechanical properties and resistance to thermal shock. Other ceramic materials, such as beryllium oxide and aluminum nitride, also find niche applications in the market, offering unique combinations of thermal and electrical properties. The choice of material depends on the specific requirements of the application, including thermal management needs, mechanical strength, electrical insulation, and cost considerations. As the demand for more efficient and reliable electronic devices continues to grow, the development and optimization of ceramic heat sink substrates remain a key focus for manufacturers and researchers in the field.

Automobile, Industrial, Energy and Electricity, Electronic Manufacturing, Aerospace, Others in the Global Ceramic Heat Sink Substrate Market:

The Global Ceramic Heat Sink Substrate Market finds extensive usage across various industries, including automobile, industrial, energy and electricity, electronic manufacturing, aerospace, and others. In the automobile industry, ceramic heat sink substrates are used in electronic control units, power modules, and LED lighting systems to manage heat and ensure reliable performance. The increasing integration of electronic components in modern vehicles, such as electric and hybrid cars, further drives the demand for efficient thermal management solutions. In industrial applications, ceramic heat sink substrates are employed in machinery and equipment that require robust thermal management to maintain operational efficiency and prevent overheating. This includes applications in automation, robotics, and heavy machinery. The energy and electricity sector also benefits from ceramic heat sink substrates, particularly in power electronics and renewable energy systems. These substrates help manage the heat generated by power converters, inverters, and other high-power devices, ensuring stable and efficient operation. In electronic manufacturing, ceramic heat sink substrates are crucial for the production of high-performance electronic devices, including semiconductors, integrated circuits, and LED displays. Their excellent thermal and electrical properties make them ideal for managing heat in densely packed electronic assemblies. The aerospace industry relies on ceramic heat sink substrates for critical applications in avionics, satellite systems, and defense electronics, where reliability and performance are paramount. Other sectors, such as telecommunications, medical devices, and consumer electronics, also utilize ceramic heat sink substrates to enhance the performance and longevity of their products. The versatility and effectiveness of ceramic heat sink substrates make them indispensable in a wide range of applications, driving their demand across multiple industries.

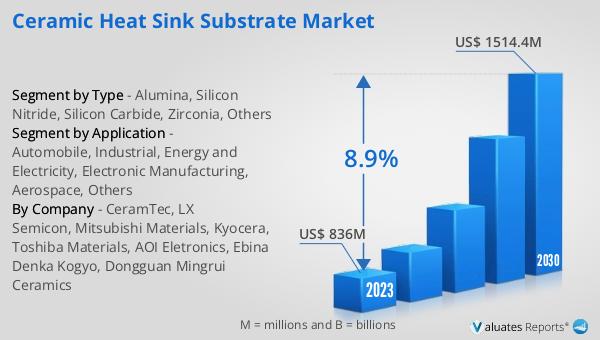

Global Ceramic Heat Sink Substrate Market Outlook:

The global Ceramic Heat Sink Substrate market was valued at US$ 836 million in 2023 and is anticipated to reach US$ 1514.4 million by 2030, witnessing a CAGR of 8.9% during the forecast period 2024-2030. This significant growth reflects the increasing demand for efficient thermal management solutions across various industries. As electronic devices become more powerful and compact, the need for effective heat dissipation becomes critical to ensure optimal performance and longevity. Ceramic heat sink substrates, with their superior thermal conductivity and electrical insulation properties, are well-suited to meet these demands. The market's expansion is driven by advancements in technology, the growing adoption of electric and hybrid vehicles, and the rising demand for high-performance electronic devices. Additionally, the increasing focus on renewable energy and the development of advanced industrial machinery further contribute to the market's growth. As a result, manufacturers and researchers are continuously working on improving the properties and performance of ceramic heat sink substrates to cater to the evolving needs of various applications. The robust growth of the Global Ceramic Heat Sink Substrate Market underscores its importance in the broader electronics and materials industries, highlighting the critical role of efficient thermal management in modern technology.

| Report Metric | Details |

| Report Name | Ceramic Heat Sink Substrate Market |

| Accounted market size in 2023 | US$ 836 million |

| Forecasted market size in 2030 | US$ 1514.4 million |

| CAGR | 8.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CeramTec, LX Semicon, Mitsubishi Materials, Kyocera, Toshiba Materials, AOI Eletronics, Ebina Denka Kogyo, Dongguan Mingrui Ceramics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |