What is Global Automotive Aluminum Alloy Die Casting Market?

The Global Automotive Aluminum Alloy Die Casting Market refers to the industry focused on producing automotive components using aluminum alloys through the die casting process. Die casting is a manufacturing technique where molten metal is injected into a mold cavity under high pressure. This method is highly efficient for mass production, offering excellent dimensional accuracy and smooth surface finishes. Aluminum alloys are favored in the automotive industry due to their lightweight nature, which contributes to improved fuel efficiency and reduced emissions. The market encompasses a wide range of applications, including engine components, chassis, suspension systems, transmission parts, and more. As the automotive industry continues to prioritize fuel efficiency and environmental sustainability, the demand for aluminum alloy die castings is expected to grow. This market is driven by advancements in die casting technology, increasing automotive production, and stringent emission regulations worldwide.

Engine Die Castings, Chassis and Suspension System Die Castings, Transmission and Driveline Die Castings, Cooling System Die Castings, External Structural Die Castings, Others in the Global Automotive Aluminum Alloy Die Casting Market:

Engine Die Castings are crucial components in the Global Automotive Aluminum Alloy Die Casting Market. These castings are used to manufacture engine blocks, cylinder heads, and other engine parts. Aluminum's lightweight properties help reduce the overall weight of the engine, leading to better fuel efficiency and performance. Chassis and Suspension System Die Castings involve the production of parts like control arms, subframes, and suspension links. These components are essential for the vehicle's structural integrity and handling performance. The use of aluminum alloys in these parts helps in weight reduction, which is critical for improving fuel economy and reducing emissions. Transmission and Driveline Die Castings include the production of transmission cases, housings, and other driveline components. Aluminum's high strength-to-weight ratio makes it an ideal material for these parts, ensuring durability and efficiency. Cooling System Die Castings involve the production of components like radiator tanks, water pump housings, and thermostat housings. Aluminum's excellent thermal conductivity makes it suitable for cooling system parts, ensuring efficient heat dissipation. External Structural Die Castings include parts like door frames, roof rails, and cross members. These components contribute to the vehicle's overall structural strength and rigidity. The use of aluminum alloys in these parts helps in weight reduction without compromising on strength. Other die castings in the automotive industry include various brackets, mounts, and housings used in different systems of the vehicle. The versatility of aluminum alloys and the efficiency of the die casting process make it possible to produce a wide range of components with high precision and consistency. The Global Automotive Aluminum Alloy Die Casting Market is driven by the increasing demand for lightweight and fuel-efficient vehicles, advancements in die casting technology, and stringent emission regulations. As the automotive industry continues to evolve, the role of aluminum alloy die castings in enhancing vehicle performance and sustainability will become even more significant.

Commercial Vehicle, Passenger Vehicle in the Global Automotive Aluminum Alloy Die Casting Market:

The usage of Global Automotive Aluminum Alloy Die Casting Market in Commercial Vehicles and Passenger Vehicles is extensive and varied. In commercial vehicles, aluminum alloy die castings are used in engine components, chassis, suspension systems, transmission parts, and more. The lightweight nature of aluminum helps in reducing the overall weight of commercial vehicles, leading to better fuel efficiency and lower operating costs. This is particularly important for commercial vehicles, which often cover long distances and have higher fuel consumption. The use of aluminum alloy die castings in engine components like cylinder heads and engine blocks helps in improving the performance and efficiency of commercial vehicle engines. In chassis and suspension systems, aluminum die castings are used to produce parts like control arms, subframes, and suspension links, which are essential for the vehicle's structural integrity and handling performance. The use of aluminum in these parts helps in weight reduction, which is critical for improving fuel economy and reducing emissions. In passenger vehicles, aluminum alloy die castings are used in a wide range of applications, including engine components, chassis, suspension systems, transmission parts, cooling systems, and external structural parts. The use of aluminum in engine components helps in reducing the overall weight of the engine, leading to better fuel efficiency and performance. In chassis and suspension systems, aluminum die castings are used to produce parts like control arms, subframes, and suspension links, which are essential for the vehicle's structural integrity and handling performance. The use of aluminum in these parts helps in weight reduction, which is critical for improving fuel economy and reducing emissions. In transmission systems, aluminum die castings are used to produce transmission cases, housings, and other driveline components. The high strength-to-weight ratio of aluminum makes it an ideal material for these parts, ensuring durability and efficiency. In cooling systems, aluminum die castings are used to produce components like radiator tanks, water pump housings, and thermostat housings. The excellent thermal conductivity of aluminum makes it suitable for cooling system parts, ensuring efficient heat dissipation. In external structural parts, aluminum die castings are used to produce components like door frames, roof rails, and cross members, which contribute to the vehicle's overall structural strength and rigidity. The use of aluminum in these parts helps in weight reduction without compromising on strength. The versatility of aluminum alloys and the efficiency of the die casting process make it possible to produce a wide range of components with high precision and consistency. The increasing demand for lightweight and fuel-efficient vehicles, advancements in die casting technology, and stringent emission regulations are driving the growth of the Global Automotive Aluminum Alloy Die Casting Market in both commercial and passenger vehicles.

Global Automotive Aluminum Alloy Die Casting Market Outlook:

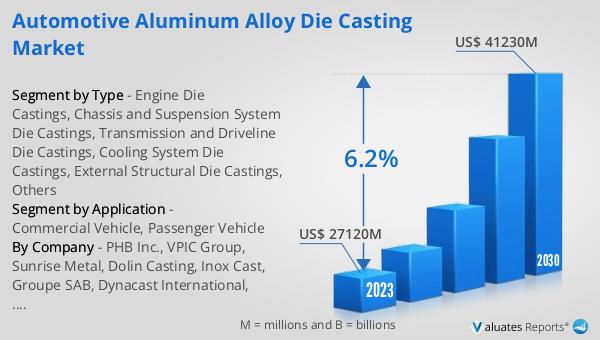

The global Automotive Aluminum Alloy Die Casting market was valued at US$ 27,120 million in 2023 and is projected to reach US$ 41,230 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.2% during the forecast period from 2024 to 2030. Among the key players in this market, China stands out as the world's largest automobile producer, accounting for approximately 32% of global production. This significant share underscores China's pivotal role in the automotive industry and its substantial influence on the aluminum alloy die casting market. The growth in this market is driven by the increasing demand for lightweight and fuel-efficient vehicles, advancements in die casting technology, and stringent emission regulations. As the automotive industry continues to evolve, the role of aluminum alloy die castings in enhancing vehicle performance and sustainability will become even more significant. The market's expansion is also supported by the growing adoption of electric vehicles, which require lightweight materials to maximize battery efficiency and range. The use of aluminum alloys in die casting provides a viable solution to meet these requirements, further driving the market's growth.

| Report Metric | Details |

| Report Name | Automotive Aluminum Alloy Die Casting Market |

| Accounted market size in 2023 | US$ 27120 million |

| Forecasted market size in 2030 | US$ 41230 million |

| CAGR | 6.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PHB Inc., VPIC Group, Sunrise Metal, Dolin Casting, Inox Cast, Groupe SAB, Dynacast International, Ryobi, Rockman Industries, Endurance, Redstone Manufacturing, Kinetic Die Casting, Inc, Acme Casting Co., Ltd., Sieg-Huao |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |