What is Global 3D Printed Microfluidic Devices Market?

The Global 3D Printed Microfluidic Devices Market is a rapidly evolving sector that leverages advanced 3D printing technology to create intricate microfluidic devices. These devices are essential for manipulating small volumes of fluids, often at the microliter or nanoliter scale, and are used in various scientific and medical applications. The market is driven by the increasing demand for personalized medicine, advancements in biotechnology, and the need for cost-effective and efficient diagnostic tools. 3D printing allows for the rapid prototyping and production of complex microfluidic structures that would be challenging to manufacture using traditional methods. This technology enables the customization of devices to meet specific research or clinical needs, enhancing the precision and functionality of microfluidic systems. As a result, the Global 3D Printed Microfluidic Devices Market is poised for significant growth, offering innovative solutions for biochemical analysis, clinical diagnostics, and other applications.

SLA, DLP, FDM, DIW in the Global 3D Printed Microfluidic Devices Market:

Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), and Direct Ink Writing (DIW) are four prominent 3D printing technologies used in the Global 3D Printed Microfluidic Devices Market. SLA is a technique that uses a laser to cure liquid resin into solid plastic, layer by layer. This method is known for its high resolution and precision, making it ideal for creating detailed microfluidic channels and structures. DLP, similar to SLA, uses a digital light projector to cure resin, but it can do so more quickly by curing entire layers at once. This results in faster production times while maintaining high accuracy, which is crucial for developing functional microfluidic devices. FDM, on the other hand, involves the extrusion of thermoplastic filaments through a heated nozzle, building the object layer by layer. While FDM is generally less precise than SLA and DLP, it is more cost-effective and suitable for producing larger, less intricate microfluidic components. DIW is a versatile technique that extrudes a wide range of materials, including ceramics, metals, and biological substances, through a nozzle to create 3D structures. This method is particularly useful for fabricating microfluidic devices with complex geometries and multiple materials, allowing for the integration of various functionalities within a single device. Each of these 3D printing technologies offers unique advantages and can be selected based on the specific requirements of the microfluidic device being developed. The choice of technology depends on factors such as the desired resolution, material properties, production speed, and cost considerations. By leveraging these advanced 3D printing techniques, researchers and manufacturers can create highly customized and efficient microfluidic devices that meet the growing demands of the biomedical and scientific communities.

Biochemical Analysis, Clinical Diagnosis, Other in the Global 3D Printed Microfluidic Devices Market:

The usage of Global 3D Printed Microfluidic Devices Market spans several critical areas, including biochemical analysis, clinical diagnosis, and other specialized applications. In biochemical analysis, these devices are used to conduct experiments that require precise control of fluid flow and mixing. They enable researchers to study complex biochemical reactions, enzyme kinetics, and cellular behaviors in a controlled environment. The ability to rapidly prototype and customize microfluidic devices using 3D printing technology allows scientists to design experiments tailored to their specific research needs, leading to more accurate and reproducible results. In clinical diagnosis, 3D printed microfluidic devices are revolutionizing the way medical tests are conducted. These devices can be used to develop point-of-care diagnostic tools that provide quick and accurate results, reducing the need for centralized laboratory testing. For example, microfluidic devices can be used to detect biomarkers for diseases such as cancer, infectious diseases, and cardiovascular conditions. The integration of 3D printing technology allows for the creation of portable and user-friendly diagnostic devices that can be used in remote or resource-limited settings, improving access to healthcare. Beyond biochemical analysis and clinical diagnosis, 3D printed microfluidic devices find applications in various other fields. They are used in environmental monitoring to detect pollutants and contaminants in water and air samples. In the pharmaceutical industry, these devices are employed for drug development and testing, enabling high-throughput screening of potential drug candidates. Additionally, microfluidic devices are used in the food and beverage industry for quality control and safety testing. The versatility and customization capabilities of 3D printed microfluidic devices make them valuable tools across a wide range of applications, driving innovation and efficiency in multiple sectors.

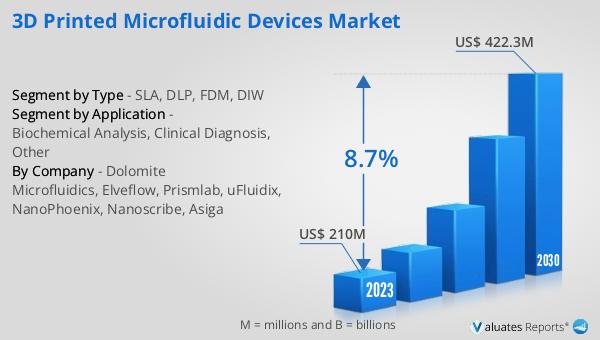

Global 3D Printed Microfluidic Devices Market Outlook:

The global market for 3D Printed Microfluidic Devices was valued at $210 million in 2023 and is projected to grow significantly, reaching $422.3 million by 2030. This growth represents a compound annual growth rate (CAGR) of 8.7% during the forecast period from 2024 to 2030. The increasing demand for advanced diagnostic tools, personalized medicine, and efficient research methodologies are key factors driving this market expansion. The ability of 3D printing technology to produce highly customized and intricate microfluidic devices quickly and cost-effectively is a major advantage, contributing to the market's growth. As more industries recognize the benefits of these devices, their adoption is expected to rise, further fueling market growth. The projected market value and growth rate highlight the significant potential and opportunities within the Global 3D Printed Microfluidic Devices Market, making it an attractive area for investment and innovation.

| Report Metric | Details |

| Report Name | 3D Printed Microfluidic Devices Market |

| Accounted market size in 2023 | US$ 210 million |

| Forecasted market size in 2030 | US$ 422.3 million |

| CAGR | 8.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dolomite Microfluidics, Elveflow, Prismlab, uFluidix, NanoPhoenix, Nanoscribe, Asiga |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |