What is Global Acoustic Fibre Panel Market?

The Global Acoustic Fibre Panel Market is a dynamic and evolving sector that focuses on the production and distribution of acoustic panels made from fibrous materials. These panels are designed to enhance sound quality by absorbing and reducing noise in various environments. Acoustic fibre panels are widely used in both residential and commercial settings, including offices, theaters, recording studios, and public spaces, to improve acoustics and create a more pleasant auditory experience. The market is driven by the increasing demand for soundproofing solutions in urban areas, where noise pollution is a growing concern. Additionally, the rise in construction activities and the need for better sound management in buildings contribute to the market's expansion. Technological advancements and innovations in materials have led to the development of more efficient and aesthetically pleasing acoustic panels, further boosting their adoption. As awareness of the benefits of acoustic panels grows, the market is expected to continue its upward trajectory, offering a range of products to meet diverse consumer needs.

Polyester Fiber Acoustic Panel, Wooden Acoustic Panel, Fabric Acoustic Panel, Other in the Global Acoustic Fibre Panel Market:

Polyester Fiber Acoustic Panels are among the most popular choices in the Global Acoustic Fibre Panel Market. These panels are crafted from 100% recycled polyester fiber, making them an eco-friendly option for sound absorption. They are lightweight, durable, and available in various colors and designs, allowing for customization to suit different aesthetic preferences. Polyester fiber panels are particularly effective in absorbing mid to high-frequency sounds, making them ideal for use in offices, schools, and public buildings where noise reduction is essential. Their ease of installation and maintenance further adds to their appeal, making them a preferred choice for many consumers. Wooden Acoustic Panels, on the other hand, offer a more traditional and natural look. Made from high-quality wood, these panels not only provide excellent sound absorption but also add a touch of elegance to any space. They are often used in concert halls, theaters, and high-end residential properties where both acoustics and aesthetics are important. Wooden panels are known for their ability to absorb low-frequency sounds, making them suitable for environments where bass control is crucial. Fabric Acoustic Panels are another popular option, known for their versatility and effectiveness in sound absorption. These panels are typically made from a combination of fabric and other sound-absorbing materials, offering a wide range of design possibilities. Fabric panels are commonly used in conference rooms, auditoriums, and home theaters, where they help to reduce echo and improve sound clarity. Their ability to blend seamlessly with existing decor makes them a favored choice for interior designers and architects. Other types of acoustic panels in the market include mineral wool panels, fiberglass panels, and foam panels, each offering unique benefits and applications. Mineral wool panels are known for their fire-resistant properties, making them suitable for use in industrial settings. Fiberglass panels are lightweight and offer excellent sound absorption, while foam panels are cost-effective and easy to install. The diversity of options available in the Global Acoustic Fibre Panel Market ensures that there is a solution for every acoustic challenge, catering to the needs of different industries and consumers.

Industrial, Commercial, Individual in the Global Acoustic Fibre Panel Market:

The usage of Global Acoustic Fibre Panel Market products spans across various sectors, including industrial, commercial, and individual applications. In industrial settings, acoustic panels are used to control noise levels in factories, manufacturing plants, and other facilities where machinery and equipment generate significant sound. By reducing noise pollution, these panels help to create a safer and more comfortable working environment for employees, improving productivity and reducing the risk of hearing damage. In commercial spaces, such as offices, retail stores, and restaurants, acoustic panels are used to enhance the acoustic quality of the environment. In offices, they help to reduce noise distractions, allowing employees to focus better and communicate more effectively. In retail stores and restaurants, acoustic panels contribute to a more pleasant shopping and dining experience by minimizing background noise and enhancing sound clarity. For individual consumers, acoustic panels are often used in home theaters, music studios, and personal workspaces to improve sound quality and create an optimal listening environment. Homeowners may also use acoustic panels in living rooms and bedrooms to reduce noise from outside sources, creating a more peaceful and relaxing atmosphere. The versatility and effectiveness of acoustic panels make them a valuable addition to any space where sound quality is a priority. As awareness of the benefits of acoustic panels continues to grow, their usage is expected to expand further, reaching new markets and applications.

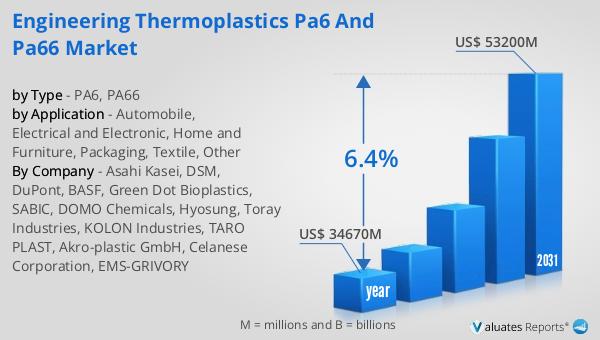

Global Acoustic Fibre Panel Market Outlook:

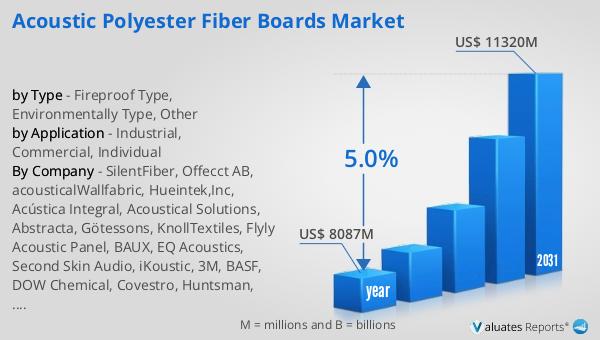

The global market for Acoustic Fibre Panels was valued at approximately $8,087 million in 2024 and is anticipated to grow to a revised size of around $11,320 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period. Among the various types of acoustic panels, Polyester Fiber Acoustic Panels stand out as the most common choice. These panels are crafted from 100% recycled polyester fiber, making them not only effective in sound absorption but also environmentally friendly. Their popularity is driven by their versatility, ease of installation, and the ability to customize them to fit different aesthetic preferences. As the demand for soundproofing solutions continues to rise, particularly in urban areas where noise pollution is a significant concern, the market for acoustic fibre panels is expected to expand. The growth is further supported by the increasing awareness of the benefits of acoustic panels in enhancing sound quality and creating more comfortable living and working environments. As technological advancements continue to improve the efficiency and design of these panels, the market is poised for sustained growth, offering a wide range of products to meet the diverse needs of consumers across various sectors.

| Report Metric | Details |

| Report Name | Acoustic Fibre Panel Market |

| Accounted market size in year | US$ 8087 million |

| Forecasted market size in 2031 | US$ 11320 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SilentFiber, Offecct AB, acousticalWallfabric, Hueintek,Inc, Acústica Integral, Acoustical Solutions, Abstracta, Götessons, KnollTextiles, Flyly Acoustic Panel, BAUX, EQ Acoustics, Second Skin Audio, iKoustic, 3M, BASF, DOW Chemical, Covestro, Huntsman, Henkel, Dupont, Toray Industries, Lyondellbasell, Sika |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |