What is Global Vertical SiC Epitaxial Equipment Market?

The Global Vertical SiC Epitaxial Equipment Market is a specialized segment within the semiconductor industry that focuses on the production and development of silicon carbide (SiC) epitaxial wafers. These wafers are crucial for manufacturing high-performance electronic devices, particularly in applications requiring high efficiency, thermal stability, and power density. SiC epitaxial equipment is used to deposit a thin layer of silicon carbide onto a substrate, creating a high-quality wafer that can be used in various electronic components. This market is driven by the increasing demand for energy-efficient devices and the growing adoption of SiC technology in power electronics, electric vehicles, and renewable energy systems. The equipment used in this market is highly specialized and requires advanced technology to ensure precision and quality in the epitaxial process. As industries continue to seek ways to improve energy efficiency and performance, the demand for SiC epitaxial equipment is expected to grow, making it a critical area of focus for manufacturers and researchers alike. The market's growth is also supported by ongoing advancements in SiC technology, which continue to expand its applications and benefits across different sectors.

4 Inch, 6 Inch, 8 Inch, Others in the Global Vertical SiC Epitaxial Equipment Market:

In the Global Vertical SiC Epitaxial Equipment Market, the size of the wafers plays a significant role in determining the equipment's application and efficiency. The market is segmented based on wafer sizes, including 4-inch, 6-inch, 8-inch, and others, each serving different needs and applications. The 4-inch wafers are among the earliest sizes used in SiC epitaxial processes. They are typically employed in research and development settings and for small-scale production. These wafers are ideal for testing new technologies and processes due to their manageable size and cost-effectiveness. However, as the demand for SiC-based devices grows, the industry is gradually shifting towards larger wafer sizes to enhance production efficiency and reduce costs. The 6-inch wafers represent a significant step forward in the SiC epitaxial equipment market. They offer a larger surface area, which allows for the production of more devices per wafer, thereby improving manufacturing efficiency and reducing the overall cost per device. This size is becoming increasingly popular in commercial production settings, particularly in industries such as automotive and renewable energy, where high-volume production is essential. The transition to 6-inch wafers is driven by the need for higher throughput and the ability to meet the growing demand for SiC-based components. The 8-inch wafers are the latest advancement in the SiC epitaxial equipment market. They provide even greater efficiency and cost benefits due to their larger size, which allows for the production of a higher number of devices per wafer. The adoption of 8-inch wafers is still in its early stages, but it is expected to gain traction as manufacturers seek to further optimize their production processes and reduce costs. The shift towards larger wafer sizes is a key trend in the market, as it enables manufacturers to scale up production and meet the increasing demand for SiC-based devices. In addition to the standard wafer sizes, the market also includes other sizes that cater to specific applications and requirements. These may include custom sizes for specialized applications or emerging technologies that require unique wafer dimensions. The diversity in wafer sizes reflects the versatility of SiC epitaxial equipment and its ability to adapt to the evolving needs of the semiconductor industry. As the market continues to grow, the demand for larger and more efficient wafer sizes is expected to increase, driving further innovation and development in SiC epitaxial equipment.

Power Equipment, Electronics and Optoelectronics, Wireless Infrastructure, Others in the Global Vertical SiC Epitaxial Equipment Market:

The Global Vertical SiC Epitaxial Equipment Market finds its application across various sectors, each benefiting from the unique properties of silicon carbide. In the realm of power equipment, SiC epitaxial wafers are crucial for developing devices that can handle high voltages and temperatures. This makes them ideal for use in power converters, inverters, and other components that require efficient energy management. The ability of SiC to operate at higher temperatures and voltages than traditional silicon makes it a preferred choice for power equipment manufacturers looking to enhance performance and reliability. In the electronics and optoelectronics sector, SiC epitaxial equipment is used to produce components that require high thermal conductivity and low power loss. This includes devices such as LEDs, laser diodes, and high-frequency transistors. The superior thermal and electrical properties of SiC make it an excellent material for these applications, where efficiency and performance are critical. The use of SiC in optoelectronics is particularly significant, as it enables the development of devices with higher brightness and longer lifespans. Wireless infrastructure is another area where the Global Vertical SiC Epitaxial Equipment Market plays a vital role. SiC-based components are used in the development of high-frequency and high-power devices, which are essential for modern wireless communication systems. The ability of SiC to operate at higher frequencies and power levels than traditional materials makes it an ideal choice for components such as RF amplifiers and switches. This is particularly important as the demand for faster and more reliable wireless communication continues to grow. Beyond these specific areas, SiC epitaxial equipment is also used in a variety of other applications, including aerospace, defense, and industrial systems. In aerospace and defense, the ability of SiC to withstand extreme conditions makes it a valuable material for developing components that require high reliability and performance. In industrial systems, SiC-based devices are used in applications such as motor drives and power supplies, where efficiency and durability are essential. The versatility of SiC epitaxial equipment and its ability to enhance performance across a wide range of applications make it a critical component of the modern semiconductor industry. As the demand for high-performance and energy-efficient devices continues to grow, the Global Vertical SiC Epitaxial Equipment Market is expected to play an increasingly important role in meeting these needs.

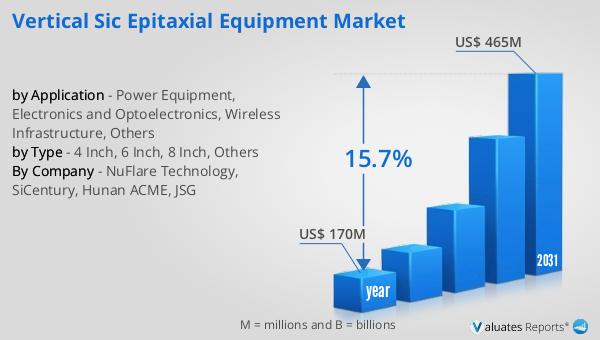

Global Vertical SiC Epitaxial Equipment Market Outlook:

The global market for Vertical SiC Epitaxial Equipment was valued at $170 million in 2024, and it is anticipated to expand significantly, reaching an estimated size of $465 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 15.7% over the forecast period. This impressive growth rate underscores the increasing demand for SiC epitaxial equipment, driven by the rising adoption of SiC technology across various industries. The market's expansion is fueled by the need for more efficient and reliable electronic devices, particularly in sectors such as automotive, renewable energy, and telecommunications. As industries continue to seek ways to improve energy efficiency and performance, the demand for SiC epitaxial equipment is expected to grow, making it a critical area of focus for manufacturers and researchers alike. The market's growth is also supported by ongoing advancements in SiC technology, which continue to expand its applications and benefits across different sectors. The increasing demand for energy-efficient devices and the growing adoption of SiC technology in power electronics, electric vehicles, and renewable energy systems are key drivers of this market's growth. As the market continues to evolve, manufacturers and researchers are expected to focus on developing more advanced and efficient SiC epitaxial equipment to meet the growing demand for high-performance electronic devices.

| Report Metric | Details |

| Report Name | Vertical SiC Epitaxial Equipment Market |

| Accounted market size in year | US$ 170 million |

| Forecasted market size in 2031 | US$ 465 million |

| CAGR | 15.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | NuFlare Technology, SiCentury, Hunan ACME, JSG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |