What is Global Nanopositioning Stages Market?

The Global Nanopositioning Stages Market is a specialized segment within the broader field of precision motion control technologies. These stages are designed to provide extremely precise positioning and movement control at the nanometer scale, which is crucial for applications requiring high accuracy and repeatability. The market encompasses a variety of products, including linear and rotary stages, which are used to manipulate objects with sub-micrometer precision. These devices are integral in fields such as semiconductor manufacturing, biotechnology, and materials science, where even the slightest positional error can lead to significant issues. The demand for nanopositioning stages is driven by the increasing need for miniaturization and precision in various high-tech industries. As technology continues to advance, the applications for nanopositioning stages are expanding, making this market a critical component of modern industrial and research activities. The market is characterized by rapid technological advancements and a high level of competition among key players, who are constantly innovating to improve the performance and capabilities of their products.

Capacitive Sensors, Strain Gauges Sensors (SGS), Linear Encoders in the Global Nanopositioning Stages Market:

Capacitive sensors, strain gauge sensors (SGS), and linear encoders are pivotal components in the Global Nanopositioning Stages Market, each offering unique advantages and applications. Capacitive sensors are renowned for their high resolution and accuracy, making them ideal for applications requiring precise position feedback. They operate by measuring changes in capacitance caused by the movement of a target object, providing real-time data that is crucial for maintaining the desired position. This type of sensor is particularly useful in environments where high precision is paramount, such as in semiconductor manufacturing and optical systems. Strain gauge sensors (SGS), on the other hand, are based on the principle of measuring the deformation or strain of an object. These sensors are typically used in applications where force, pressure, or weight measurements are required. SGS are known for their robustness and ability to operate in harsh environments, making them suitable for industrial applications where durability is a key concern. Linear encoders provide position feedback by converting the position of a scale into an electronic signal, which can then be interpreted by a control system. They are widely used in applications requiring high-speed and high-accuracy positioning, such as in CNC machines and robotics. The choice between these sensors often depends on the specific requirements of the application, including factors such as environmental conditions, required precision, and budget constraints. Each sensor type has its own set of advantages and limitations, and understanding these is crucial for selecting the right solution for a given application. In the context of the Global Nanopositioning Stages Market, capacitive sensors are the most widely used, accounting for a significant share of the market. This is largely due to their superior accuracy and resolution, which are critical for many high-tech applications. However, strain gauge sensors and linear encoders also play important roles, particularly in applications where their specific strengths can be leveraged. As the demand for precision and miniaturization continues to grow, the importance of these sensors in the nanopositioning stages market is expected to increase, driving further innovation and development in this field.

Industrial Use, Research Use in the Global Nanopositioning Stages Market:

The Global Nanopositioning Stages Market finds extensive usage in both industrial and research applications, each with its own set of requirements and challenges. In industrial settings, nanopositioning stages are crucial for processes that demand high precision and repeatability. Industries such as semiconductor manufacturing, aerospace, and automotive rely heavily on these stages to ensure the accuracy and quality of their products. For instance, in semiconductor manufacturing, nanopositioning stages are used in lithography and inspection processes, where even the slightest positional error can lead to defects in the final product. Similarly, in the aerospace industry, these stages are used in the assembly and testing of components, where precision is critical to ensure the safety and performance of the final product. In research applications, nanopositioning stages are used in a wide range of scientific experiments and studies. They are essential in fields such as materials science, biology, and physics, where precise control over the position of samples or instruments is required. For example, in materials science, nanopositioning stages are used to manipulate samples at the atomic level, allowing researchers to study their properties and behavior in detail. In biology, these stages are used in microscopy and imaging applications, where precise positioning is crucial for obtaining high-quality images. The versatility and precision of nanopositioning stages make them indispensable tools in both industrial and research settings. However, the specific requirements and challenges of each application can vary significantly, necessitating careful consideration when selecting the appropriate stage for a given task. Factors such as the required range of motion, load capacity, and environmental conditions must be taken into account to ensure optimal performance and reliability. As technology continues to advance, the applications for nanopositioning stages are expected to expand, driving further growth and innovation in this market.

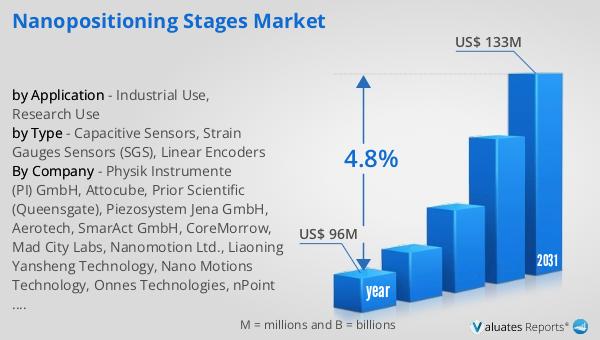

Global Nanopositioning Stages Market Outlook:

The global market for nanopositioning stages was valued at approximately $96 million in 2024 and is anticipated to grow to around $133 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.8% over the forecast period. The market is characterized by a high level of competition, with the top five players accounting for about 44% of the total market share. The Asia-Pacific region is the largest market for nanopositioning systems, holding approximately 42% of the global share, followed by North America and Europe, which account for about 26% and 22% of the market, respectively. In terms of product types, capacitive sensors represent the largest segment, making up about 55% of the market. This is largely due to their superior accuracy and resolution, which are critical for many high-tech applications. In terms of applications, industrial use is the largest field, accounting for approximately 60% of the market. This reflects the growing demand for precision and miniaturization in various industrial sectors, driving the need for advanced nanopositioning solutions. The market is expected to continue growing as technology advances and the demand for precision and miniaturization increases across various industries.

| Report Metric | Details |

| Report Name | Nanopositioning Stages Market |

| Accounted market size in year | US$ 96 million |

| Forecasted market size in 2031 | US$ 133 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Physik Instrumente (PI) GmbH, Attocube, Prior Scientific (Queensgate), Piezosystem Jena GmbH, Aerotech, SmarAct GmbH, CoreMorrow, Mad City Labs, Nanomotion Ltd., Liaoning Yansheng Technology, Nano Motions Technology, Onnes Technologies, nPoint (Motion Solutions), OME Technology, Dynamic Structures and Materials, Nanomagnetics Instruments, Montana Instruments, Anhui ZeYou Technology, LAB Motion Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |