What is Global Commercial Ion Implantation Systems Market?

The Global Commercial Ion Implantation Systems Market is a specialized sector within the broader field of semiconductor manufacturing and materials engineering. Ion implantation is a critical process used to modify the properties of materials, particularly semiconductors, by embedding ions into a substrate. This technique is essential for creating integrated circuits and other semiconductor devices, as it allows for precise control over the electrical properties of the materials. The market for these systems is driven by the increasing demand for advanced electronic devices, such as smartphones, tablets, and other consumer electronics, which require sophisticated semiconductor components. Additionally, the rise of technologies like 5G, artificial intelligence, and the Internet of Things (IoT) further fuels the need for advanced ion implantation systems. These systems are also used in the photovoltaic industry to enhance the efficiency of solar cells. As industries continue to innovate and develop new applications for semiconductors, the demand for commercial ion implantation systems is expected to grow, making it a vital component of the global technology landscape.

Medium-Current Implanter, High-Current Implanter, High-Energy Implanter in the Global Commercial Ion Implantation Systems Market:

In the realm of Global Commercial Ion Implantation Systems, three primary types of implanters are pivotal: Medium-Current Implanter, High-Current Implanter, and High-Energy Implanter. Each of these plays a distinct role in the semiconductor manufacturing process, catering to different requirements based on the desired outcome of the implantation. Medium-Current Implanters are typically used for applications that require moderate ion doses and energies. They are versatile and can handle a wide range of implantation tasks, making them suitable for general-purpose semiconductor manufacturing. These implanters are often employed in the production of integrated circuits where precise control over doping levels is necessary to achieve the desired electrical characteristics. High-Current Implanters, on the other hand, are designed for applications that require high doses of ions. They are essential in processes where a large number of ions need to be implanted in a short period, such as in the production of power devices and certain types of memory chips. The ability to deliver high doses efficiently makes these implanters crucial for high-volume manufacturing environments where time and efficiency are of the essence. High-Energy Implanters are used when ions need to penetrate deeper into the substrate. This capability is vital for applications that require the modification of material properties at greater depths, such as in the creation of buried layers in semiconductor devices. High-energy implantation is also used in the development of advanced materials and devices that require specific structural modifications. Each type of implanter is equipped with sophisticated control systems to ensure precision and accuracy during the implantation process. The choice of implanter depends on various factors, including the type of semiconductor device being manufactured, the desired electrical properties, and the specific requirements of the production process. As the demand for more advanced and efficient semiconductor devices continues to grow, the role of these implanters becomes increasingly important. Manufacturers are continually innovating to improve the performance and capabilities of these systems, ensuring they can meet the evolving needs of the semiconductor industry. The integration of advanced technologies, such as machine learning and automation, into ion implantation systems is also enhancing their efficiency and precision, further driving their adoption in various industries.

Semiconductor Industry, Photovoltaic (PV) Industry in the Global Commercial Ion Implantation Systems Market:

The Global Commercial Ion Implantation Systems Market finds significant applications in both the Semiconductor Industry and the Photovoltaic (PV) Industry. In the Semiconductor Industry, ion implantation is a critical process used to modify the electrical properties of semiconductor materials. This process is essential for the production of integrated circuits, which are the building blocks of modern electronic devices. By precisely controlling the type and concentration of ions implanted into the semiconductor substrate, manufacturers can tailor the electrical characteristics of the material to meet specific requirements. This capability is crucial for the development of advanced semiconductor devices, such as microprocessors, memory chips, and sensors, which are used in a wide range of applications, from consumer electronics to automotive systems. In the Photovoltaic Industry, ion implantation is used to enhance the efficiency of solar cells. By modifying the properties of the materials used in solar cells, manufacturers can improve their ability to convert sunlight into electricity. This process is particularly important for the development of high-efficiency solar cells, which are essential for reducing the cost of solar energy and making it more competitive with traditional energy sources. Ion implantation allows for precise control over the doping levels in solar cell materials, enabling manufacturers to optimize their performance and efficiency. As the demand for renewable energy continues to grow, the role of ion implantation in the photovoltaic industry is becoming increasingly important. Both industries benefit from the precision and control offered by ion implantation systems, which allow for the development of advanced materials and devices with tailored properties. As technology continues to evolve, the applications of ion implantation are expected to expand, driving further growth in the Global Commercial Ion Implantation Systems Market.

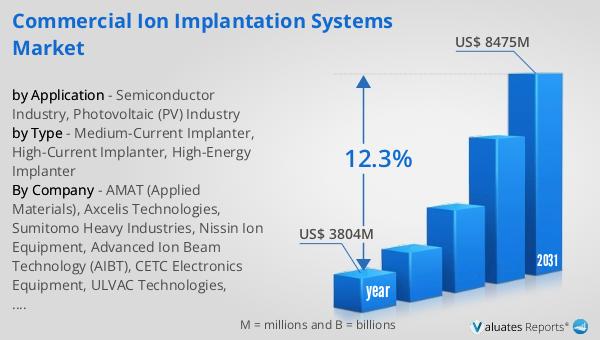

Global Commercial Ion Implantation Systems Market Outlook:

The global market for Commercial Ion Implantation Systems was valued at $3,804 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $8,475 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 12.3% during the forecast period. This impressive growth trajectory underscores the increasing demand for advanced ion implantation systems across various industries, driven by the rapid advancements in technology and the growing need for sophisticated semiconductor devices. The expansion of the market is also fueled by the rising adoption of technologies such as 5G, artificial intelligence, and the Internet of Things (IoT), which require advanced semiconductor components. Additionally, the push towards renewable energy sources, particularly solar energy, is contributing to the demand for ion implantation systems in the photovoltaic industry. As industries continue to innovate and develop new applications for semiconductors, the market for commercial ion implantation systems is expected to experience robust growth, making it a vital component of the global technology landscape. The projected growth of the market reflects the increasing importance of ion implantation systems in the development of advanced electronic devices and renewable energy solutions.

| Report Metric | Details |

| Report Name | Commercial Ion Implantation Systems Market |

| Accounted market size in year | US$ 3804 million |

| Forecasted market size in 2031 | US$ 8475 million |

| CAGR | 12.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AMAT (Applied Materials), Axcelis Technologies, Sumitomo Heavy Industries, Nissin Ion Equipment, Advanced Ion Beam Technology (AIBT), CETC Electronics Equipment, ULVAC Technologies, Kingstone Semiconductor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |