What is Global Mold Temperature Sensor Market?

The Global Mold Temperature Sensor Market is a specialized segment within the broader temperature sensor industry, focusing on devices used to monitor and control the temperature of molds in various manufacturing processes. These sensors are crucial in ensuring the quality and efficiency of production in industries such as plastics, automotive, and electronics. By providing accurate temperature readings, mold temperature sensors help maintain optimal conditions for molding processes, preventing defects and improving the overall quality of the final product. The market for these sensors is driven by the increasing demand for high-quality, precision-engineered products, as well as the growing adoption of automation and advanced manufacturing technologies. As industries continue to seek ways to enhance productivity and reduce waste, the role of mold temperature sensors becomes increasingly important. These sensors are available in various types, including thermocouples, resistance temperature detectors (RTDs), and other advanced technologies, each offering unique benefits and applications. The global market for mold temperature sensors is characterized by a diverse range of products and solutions, catering to the specific needs of different industries and applications. As a result, the market is expected to experience steady growth in the coming years, driven by technological advancements and the increasing emphasis on quality and efficiency in manufacturing processes.

Thermocouple, RTDs, Other in the Global Mold Temperature Sensor Market:

Thermocouples, RTDs, and other types of temperature sensors play a crucial role in the Global Mold Temperature Sensor Market, each offering distinct advantages and applications. Thermocouples are among the most commonly used temperature sensors in the industry due to their wide temperature range, durability, and cost-effectiveness. They consist of two different metals joined at one end, creating a junction that produces a voltage proportional to the temperature difference between the junction and the other ends of the metals. This voltage is then measured and converted into a temperature reading. Thermocouples are highly versatile and can be used in a variety of environments, making them ideal for applications where rapid temperature changes occur, such as in injection molding and die casting processes. Their ability to withstand high temperatures and harsh conditions makes them a popular choice in industrial settings. Resistance Temperature Detectors (RTDs), on the other hand, offer high accuracy and stability, making them suitable for applications where precise temperature measurements are critical. RTDs work on the principle that the resistance of a metal changes with temperature. They are typically made of pure platinum, which provides excellent linearity and repeatability over a wide temperature range. RTDs are often used in applications where long-term stability and accuracy are essential, such as in the production of high-precision components. While they are generally more expensive than thermocouples, their reliability and precision make them a preferred choice in many industries. In addition to thermocouples and RTDs, the Global Mold Temperature Sensor Market also includes other advanced technologies, such as infrared sensors and fiber optic sensors. Infrared sensors measure temperature by detecting the infrared radiation emitted by an object, allowing for non-contact temperature measurement. This makes them ideal for applications where direct contact with the mold is not possible or desirable. Fiber optic sensors, on the other hand, use light to measure temperature and are known for their immunity to electromagnetic interference, making them suitable for use in environments with high levels of electrical noise. These advanced sensors offer unique benefits and are often used in specialized applications where traditional sensors may not be suitable. The choice of sensor type depends on various factors, including the specific requirements of the application, the operating environment, and the desired level of accuracy and reliability. As the Global Mold Temperature Sensor Market continues to evolve, manufacturers are investing in research and development to create innovative solutions that meet the changing needs of the industry. This includes the development of sensors with enhanced performance characteristics, such as faster response times, higher accuracy, and improved durability. Additionally, the integration of smart technologies and IoT capabilities into temperature sensors is becoming increasingly common, allowing for real-time monitoring and data analysis. This enables manufacturers to optimize their processes, reduce downtime, and improve overall efficiency. As a result, the Global Mold Temperature Sensor Market is expected to continue growing, driven by the increasing demand for high-quality, precision-engineered products and the ongoing advancements in sensor technology.

Injection Molding, Die Casting, Other in the Global Mold Temperature Sensor Market:

The Global Mold Temperature Sensor Market finds extensive usage in various areas, including injection molding, die casting, and other manufacturing processes. In injection molding, mold temperature sensors play a critical role in ensuring the quality and consistency of the final product. Injection molding involves injecting molten material, typically plastic, into a mold cavity, where it cools and solidifies into the desired shape. Maintaining the correct mold temperature is essential to prevent defects such as warping, sink marks, and incomplete filling. Mold temperature sensors provide real-time temperature data, allowing operators to adjust the process parameters as needed to achieve optimal results. By ensuring uniform temperature distribution across the mold, these sensors help improve the quality of the molded parts and reduce the likelihood of defects. In die casting, mold temperature sensors are equally important in maintaining the quality and efficiency of the process. Die casting involves forcing molten metal into a mold cavity under high pressure, where it cools and solidifies. The temperature of the mold plays a crucial role in determining the quality of the cast parts, as it affects the cooling rate and solidification process. Mold temperature sensors provide accurate temperature readings, enabling operators to control the cooling process and ensure consistent quality. By maintaining the optimal mold temperature, these sensors help prevent defects such as porosity, shrinkage, and surface imperfections, resulting in high-quality cast parts. In addition to injection molding and die casting, mold temperature sensors are used in various other manufacturing processes where temperature control is critical. This includes processes such as blow molding, compression molding, and extrusion, where maintaining the correct mold temperature is essential for achieving the desired product quality and performance. In blow molding, for example, mold temperature sensors help ensure uniform wall thickness and prevent defects such as uneven cooling and warping. In compression molding, these sensors provide precise temperature control, allowing for the production of high-quality composite parts with consistent properties. The use of mold temperature sensors in these processes helps manufacturers achieve higher efficiency, reduce waste, and improve the overall quality of their products. As industries continue to seek ways to enhance productivity and reduce costs, the demand for mold temperature sensors is expected to grow, driven by the increasing emphasis on quality and efficiency in manufacturing processes.

Global Mold Temperature Sensor Market Outlook:

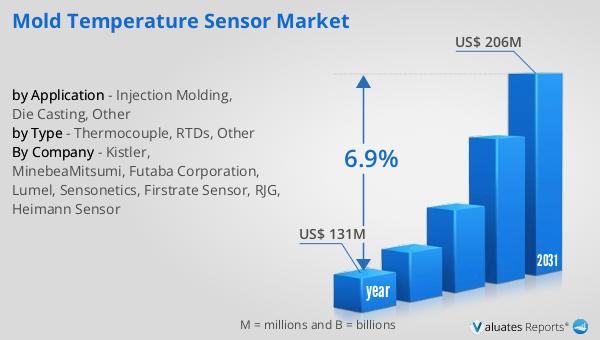

The outlook for the Global Mold Temperature Sensor Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 131 million, reflecting the significant demand for these sensors across various industries. As manufacturers continue to prioritize quality and efficiency in their production processes, the need for accurate and reliable temperature monitoring solutions is expected to increase. By 2031, the market is projected to reach a revised size of US$ 206 million, representing a compound annual growth rate (CAGR) of 6.9% during the forecast period. This growth can be attributed to several factors, including the increasing adoption of automation and advanced manufacturing technologies, as well as the rising demand for high-quality, precision-engineered products. As industries continue to evolve and embrace new technologies, the role of mold temperature sensors becomes increasingly important in ensuring the quality and efficiency of production processes. The market is characterized by a diverse range of products and solutions, catering to the specific needs of different industries and applications. As a result, manufacturers are investing in research and development to create innovative solutions that meet the changing needs of the industry. This includes the development of sensors with enhanced performance characteristics, such as faster response times, higher accuracy, and improved durability. Additionally, the integration of smart technologies and IoT capabilities into temperature sensors is becoming increasingly common, allowing for real-time monitoring and data analysis. This enables manufacturers to optimize their processes, reduce downtime, and improve overall efficiency. As the Global Mold Temperature Sensor Market continues to grow, it presents significant opportunities for manufacturers and suppliers to expand their product offerings and capture a larger share of the market. With the increasing emphasis on quality and efficiency in manufacturing processes, the demand for mold temperature sensors is expected to remain strong, driving further growth and innovation in the industry.

| Report Metric | Details |

| Report Name | Mold Temperature Sensor Market |

| Accounted market size in year | US$ 131 million |

| Forecasted market size in 2031 | US$ 206 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kistler, MinebeaMitsumi, Futaba Corporation, Lumel, Sensonetics, Firstrate Sensor, RJG, Heimann Sensor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |