What is Global Primary Gas Insulated Switchgear Market?

The Global Primary Gas Insulated Switchgear Market refers to the worldwide industry focused on the production and distribution of gas-insulated switchgear (GIS) systems. These systems are essential components in electrical power distribution networks, providing a compact and efficient solution for controlling and protecting electrical circuits. Unlike traditional air-insulated switchgear, GIS uses sulfur hexafluoride (SF6) gas to insulate the electrical components, allowing for a more compact design. This makes GIS particularly valuable in urban areas where space is limited. The market encompasses a wide range of applications, including power generation, transmission, and distribution, as well as industrial and commercial sectors. As the demand for reliable and efficient power supply grows, the Global Primary Gas Insulated Switchgear Market is expected to expand, driven by technological advancements and the increasing need for sustainable energy solutions. The market is characterized by a diverse range of manufacturers and suppliers, each offering various types of GIS systems tailored to specific applications and customer requirements.

Normal Type, Compact in the Global Primary Gas Insulated Switchgear Market:

In the Global Primary Gas Insulated Switchgear Market, two main types of switchgear are prevalent: Normal Type and Compact Type. The Normal Type gas-insulated switchgear is typically used in applications where space constraints are not a primary concern. These systems are designed to handle high voltage levels and are often employed in large-scale power distribution networks. They offer robust performance and reliability, making them suitable for critical infrastructure projects. The Normal Type switchgear is characterized by its larger size and higher capacity, which allows it to manage substantial electrical loads efficiently. On the other hand, the Compact Type gas-insulated switchgear is specifically designed for environments where space is at a premium. These systems are engineered to provide the same level of performance as their larger counterparts but in a much smaller footprint. The Compact Type is ideal for urban settings, industrial plants, and other locations where minimizing space usage is crucial. Despite their smaller size, these systems maintain high levels of safety and efficiency, thanks to advanced engineering and the use of SF6 gas for insulation. Both types of switchgear play a vital role in modern power distribution networks, ensuring the safe and reliable delivery of electricity to end-users. The choice between Normal and Compact Type switchgear depends on various factors, including the specific requirements of the installation site, the available space, and the desired level of performance. As the demand for electricity continues to rise globally, the need for efficient and reliable switchgear solutions will remain a key driver of the market. Manufacturers are continually innovating to improve the performance and efficiency of both Normal and Compact Type gas-insulated switchgear, ensuring they meet the evolving needs of the power industry.

Primary Substations, Steelwork Plants, Refinery Plants, Others in the Global Primary Gas Insulated Switchgear Market:

The Global Primary Gas Insulated Switchgear Market finds extensive usage across various sectors, including primary substations, steelwork plants, refinery plants, and other industrial applications. In primary substations, gas-insulated switchgear is crucial for managing the flow of electricity from power generation facilities to distribution networks. These substations serve as critical nodes in the electrical grid, ensuring the efficient and reliable transmission of power. The compact design of gas-insulated switchgear makes it ideal for use in substations located in urban areas, where space is limited. In steelwork plants, gas-insulated switchgear is used to manage the high electrical loads required for steel production processes. These plants demand robust and reliable power distribution systems to ensure continuous operation and minimize downtime. The use of gas-insulated switchgear in steelwork plants helps to enhance operational efficiency and safety, reducing the risk of electrical faults and equipment failures. Similarly, in refinery plants, gas-insulated switchgear plays a vital role in managing the complex electrical systems required for refining processes. These plants require highly reliable power distribution systems to maintain continuous operation and ensure the safety of personnel and equipment. The use of gas-insulated switchgear in refinery plants helps to minimize the risk of electrical failures and improve overall operational efficiency. Beyond these specific applications, gas-insulated switchgear is also used in a wide range of other industrial and commercial settings, including data centers, airports, and manufacturing facilities. The versatility and reliability of gas-insulated switchgear make it an essential component of modern power distribution networks, ensuring the safe and efficient delivery of electricity to end-users across various sectors.

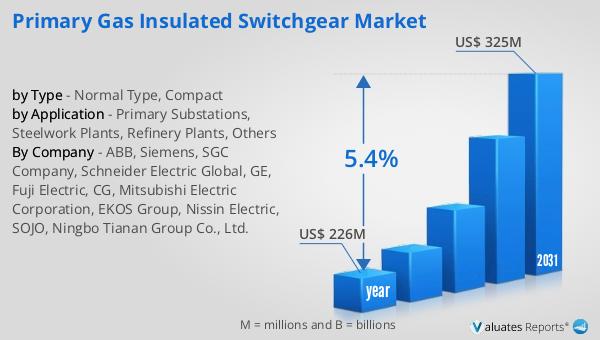

Global Primary Gas Insulated Switchgear Market Outlook:

The global market for Primary Gas Insulated Switchgear was valued at $226 million in 2024, with projections indicating a growth to $325 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.4% over the forecast period. This upward trend is driven by several factors, including the increasing demand for reliable and efficient power distribution systems, particularly in urban areas where space is limited. The compact design of gas-insulated switchgear makes it an attractive solution for these environments, offering high performance and reliability in a smaller footprint. Additionally, the growing focus on sustainable energy solutions and the need to modernize aging power infrastructure are contributing to the market's expansion. As countries around the world invest in upgrading their electrical grids, the demand for advanced switchgear solutions is expected to rise. The market is characterized by a diverse range of manufacturers and suppliers, each offering various types of gas-insulated switchgear systems tailored to specific applications and customer requirements. As the market continues to grow, manufacturers are likely to focus on innovation and technological advancements to meet the evolving needs of the power industry. This includes the development of more efficient and environmentally friendly switchgear solutions that can help reduce the environmental impact of power distribution systems. Overall, the Global Primary Gas Insulated Switchgear Market is poised for significant growth in the coming years, driven by the increasing demand for reliable and efficient power distribution solutions.

| Report Metric | Details |

| Report Name | Primary Gas Insulated Switchgear Market |

| Accounted market size in year | US$ 226 million |

| Forecasted market size in 2031 | US$ 325 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, Siemens, SGC Company, Schneider Electric Global, GE, Fuji Electric, CG, Mitsubishi Electric Corporation, EKOS Group, Nissin Electric, SOJO, Ningbo Tianan Group Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |