What is Hand Push Thermoplastic Road Marking Machine - Global Market?

The Hand Push Thermoplastic Road Marking Machine is a specialized piece of equipment used globally for applying thermoplastic markings on roads. These machines are designed to be manually operated, making them ideal for smaller projects or areas where larger, vehicle-mounted machines cannot access. The thermoplastic material used in these machines is a type of plastic that becomes pliable when heated and hardens upon cooling, creating durable and highly visible road markings. This technology is widely used for marking lanes, pedestrian crossings, and other road symbols, providing essential guidance and safety information to drivers and pedestrians. The global market for these machines is driven by the increasing need for road safety and infrastructure development. As urbanization and vehicle numbers grow, so does the demand for clear and effective road markings. The market is characterized by a variety of machine capacities and features, catering to different project sizes and requirements. Manufacturers are continually innovating to improve the efficiency, ease of use, and environmental impact of these machines, ensuring they meet the evolving needs of road maintenance and construction sectors worldwide.

Capacity: Less than 80KG, Capacity: 80 to 120KG, Capacity: ,More than 120KG in the Hand Push Thermoplastic Road Marking Machine - Global Market:

The Hand Push Thermoplastic Road Marking Machines are categorized based on their capacity, which determines the amount of thermoplastic material they can hold and apply before needing a refill. Machines with a capacity of less than 80KG are typically used for smaller projects or areas with limited access. These machines are lightweight and easy to maneuver, making them ideal for marking small roads, parking lots, or community areas. They are designed for quick setup and operation, allowing for efficient marking without the need for extensive training or experience. The compact size of these machines also makes them suitable for projects where space is limited or where larger machines cannot be used. Machines with a capacity of 80 to 120KG are more versatile and can handle medium-sized projects. They offer a balance between capacity and maneuverability, making them suitable for a wide range of applications. These machines are often used for marking urban roads, highways, and other areas where a moderate amount of marking is required. They are designed to be durable and reliable, with features that enhance their performance and ease of use. Machines with a capacity of more than 120KG are designed for large-scale projects and are capable of applying a significant amount of thermoplastic material before needing a refill. These machines are typically used for marking highways, airports, and other large areas where extensive marking is required. They are built to withstand heavy use and are equipped with advanced features that improve their efficiency and accuracy. Despite their larger size, these machines are designed to be easy to operate, with controls that allow for precise application of markings. The global market for these machines is driven by the increasing demand for road safety and infrastructure development, with manufacturers continually innovating to improve the performance and capabilities of their machines.

Highway, Community, Airport, Others in the Hand Push Thermoplastic Road Marking Machine - Global Market:

The Hand Push Thermoplastic Road Marking Machine is widely used in various areas, including highways, communities, airports, and other locations. On highways, these machines are essential for applying lane markings, edge lines, and other symbols that guide drivers and enhance road safety. The durability and visibility of thermoplastic markings make them ideal for high-traffic areas, where markings need to withstand heavy use and harsh weather conditions. In community areas, these machines are used to mark pedestrian crossings, parking spaces, and other areas where clear and visible markings are essential for safety and organization. The compact size and maneuverability of hand push machines make them ideal for use in residential areas, where space may be limited and access restricted. At airports, these machines are used to mark runways, taxiways, and other areas where precise and durable markings are critical for safety and efficiency. The ability to apply thermoplastic markings quickly and accurately makes these machines an essential tool for airport maintenance and operations. In other areas, such as industrial sites, sports facilities, and school grounds, these machines are used to apply a variety of markings, from safety lines to sports field boundaries. The versatility and ease of use of hand push thermoplastic road marking machines make them a valuable tool for a wide range of applications, ensuring that markings are applied quickly, accurately, and efficiently.

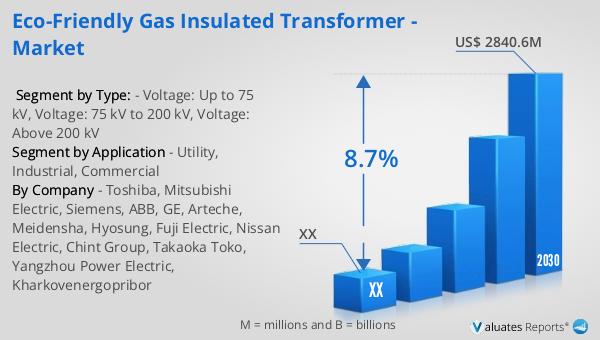

Hand Push Thermoplastic Road Marking Machine - Global Market Outlook:

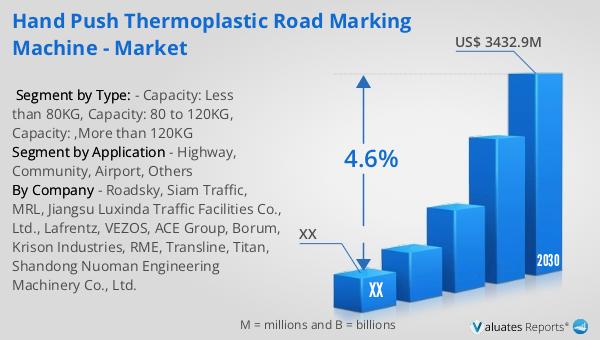

In 2023, the global market for Hand Push Thermoplastic Road Marking Machines was valued at approximately US$ 2360 million. This market is projected to grow, reaching an estimated size of US$ 3432.9 million by 2030, with a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for road safety and infrastructure development worldwide. The North American market for these machines was also valued in 2023, with expectations of growth by 2030. However, specific figures for the North American market's value and growth rate during the forecast period are not provided. The overall market outlook indicates a positive trend, driven by the need for effective road marking solutions in various regions. As urbanization and vehicle numbers continue to rise, the demand for clear and durable road markings is expected to increase, supporting the growth of the Hand Push Thermoplastic Road Marking Machine market globally. Manufacturers are likely to focus on innovation and efficiency to meet the evolving needs of the market, ensuring that these machines remain a vital tool for road maintenance and construction projects worldwide.

| Report Metric | Details |

| Report Name | Hand Push Thermoplastic Road Marking Machine - Market |

| Forecasted market size in 2030 | US$ 3432.9 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Roadsky, Siam Traffic, MRL, Jiangsu Luxinda Traffic Facilities Co., Ltd., Lafrentz, VEZOS, ACE Group, Borum, Krison Industries, RME, Transline, Titan, Shandong Nuoman Engineering Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |