What is Alloy Rupture Discs - Global Market?

Alloy rupture discs are critical safety devices used in various industries to protect equipment from overpressure conditions. These discs are designed to rupture at a predetermined pressure, allowing excess pressure to be safely vented away, thus preventing potential damage or catastrophic failure of equipment. The global market for alloy rupture discs is driven by the increasing demand for safety measures in industries such as oil and gas, chemical, aerospace, and pharmaceuticals. These discs are made from various alloys, each offering specific properties that make them suitable for different applications. The market is characterized by a diverse range of products tailored to meet the specific needs of different industries, with manufacturers focusing on innovation and technological advancements to enhance the performance and reliability of these safety devices. As industries continue to prioritize safety and regulatory compliance, the demand for alloy rupture discs is expected to grow, making it a vital component in the global safety equipment market. The market's growth is also supported by the increasing industrialization and stringent safety regulations across the globe, which necessitate the use of reliable pressure relief solutions like alloy rupture discs.

Alloy 200, Alloy 400, Alloy 600, Others in the Alloy Rupture Discs - Global Market:

Alloy rupture discs are manufactured using various alloys, each offering unique properties that cater to specific industrial needs. Alloy 200, for instance, is a commercially pure nickel alloy known for its excellent corrosion resistance and high thermal and electrical conductivity. This makes it ideal for applications in the chemical and food processing industries, where resistance to corrosive environments is crucial. Alloy 400, on the other hand, is a nickel-copper alloy that offers superior strength and resistance to acidic and alkaline environments. It is widely used in the marine and chemical processing industries due to its ability to withstand harsh conditions. Alloy 600 is a nickel-chromium-iron alloy known for its high-temperature strength and oxidation resistance. This makes it suitable for applications in the aerospace and heat-treating industries, where materials are exposed to extreme temperatures. Other alloys used in rupture discs include Alloy 625 and Alloy C-276, which offer exceptional resistance to a wide range of corrosive environments and are used in industries such as oil and gas, chemical processing, and pollution control. The choice of alloy depends on the specific requirements of the application, including the operating environment, temperature, and pressure conditions. Manufacturers continue to innovate and develop new alloys to meet the evolving needs of various industries, ensuring that alloy rupture discs remain a critical component in industrial safety systems. The global market for alloy rupture discs is characterized by a wide range of products, each designed to meet the specific needs of different industries. Manufacturers focus on developing high-performance discs that offer reliable pressure relief solutions, ensuring the safety and efficiency of industrial operations. As industries continue to evolve and face new challenges, the demand for advanced alloy rupture discs is expected to grow, driving innovation and technological advancements in the market.

Oil and Gas, Chemical, Aerospace, Pharmaceutical, Others in the Alloy Rupture Discs - Global Market:

Alloy rupture discs play a crucial role in ensuring safety and operational efficiency across various industries. In the oil and gas sector, these discs are used to protect equipment such as pipelines, storage tanks, and pressure vessels from overpressure conditions. The harsh environments and high-pressure conditions in this industry necessitate the use of robust and reliable pressure relief solutions, making alloy rupture discs an essential component in oil and gas operations. In the chemical industry, alloy rupture discs are used to safeguard equipment from overpressure caused by chemical reactions or process upsets. The corrosive nature of many chemicals requires the use of discs made from alloys that offer excellent corrosion resistance, ensuring the longevity and reliability of the pressure relief system. In the aerospace industry, alloy rupture discs are used in various applications, including fuel systems and hydraulic systems, to prevent overpressure and ensure the safety of aircraft operations. The high-temperature and high-pressure conditions in this industry require the use of discs made from alloys that offer superior strength and resistance to extreme conditions. In the pharmaceutical industry, alloy rupture discs are used to protect equipment such as reactors and storage tanks from overpressure, ensuring the safety and integrity of the manufacturing process. The stringent regulatory requirements in this industry necessitate the use of reliable and high-performance pressure relief solutions. Other industries that use alloy rupture discs include food and beverage, power generation, and water treatment, where they play a vital role in ensuring safety and operational efficiency. The versatility and reliability of alloy rupture discs make them an indispensable component in various industrial applications, driving their demand in the global market. As industries continue to prioritize safety and regulatory compliance, the use of alloy rupture discs is expected to grow, supporting the overall growth of the global market.

Alloy Rupture Discs - Global Market Outlook:

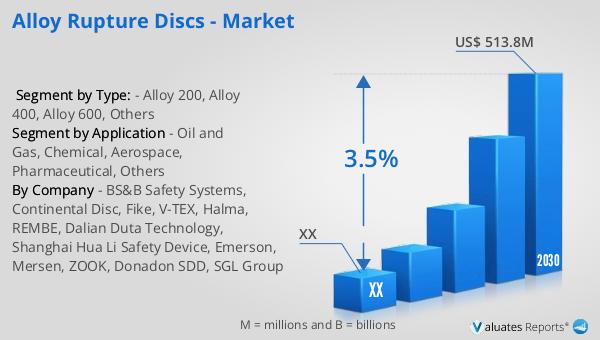

The global market for alloy rupture discs was valued at approximately $401 million in 2023, with projections indicating a growth to around $513.8 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.5% from 2024 to 2030. The North American market, a significant segment of the global market, was also valued at a substantial figure in 2023, with expectations of continued growth through 2030. The steady increase in market size reflects the growing demand for safety and pressure relief solutions across various industries. The market's expansion is driven by factors such as increasing industrialization, stringent safety regulations, and the need for reliable pressure relief systems in critical applications. As industries continue to evolve and face new challenges, the demand for advanced alloy rupture discs is expected to grow, driving innovation and technological advancements in the market. The focus on safety and regulatory compliance is a key driver of market growth, as industries seek to ensure the safety and efficiency of their operations. The global market for alloy rupture discs is poised for steady growth, supported by the increasing demand for reliable and high-performance pressure relief solutions across various industries.

| Report Metric | Details |

| Report Name | Alloy Rupture Discs - Market |

| Forecasted market size in 2030 | US$ 513.8 million |

| CAGR | 3.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BS&B Safety Systems, Continental Disc, Fike, V-TEX, Halma, REMBE, Dalian Duta Technology, Shanghai Hua Li Safety Device, Emerson, Mersen, ZOOK, Donadon SDD, SGL Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |