What is Stainless Steel Rupture Discs - Global Market?

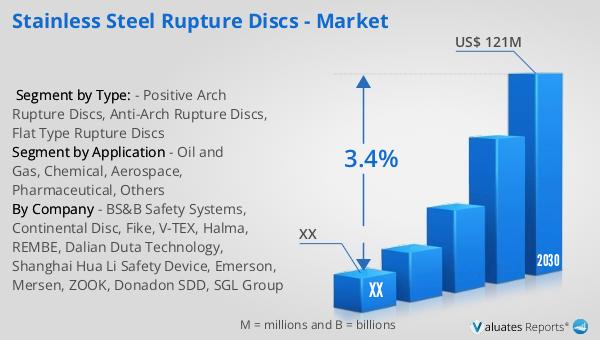

Stainless steel rupture discs are critical safety devices used in various industries to prevent overpressure situations that could lead to equipment failure or catastrophic events. These discs are designed to burst at a predetermined pressure, thereby relieving excess pressure and protecting equipment and personnel. The global market for stainless steel rupture discs is driven by the increasing demand for safety measures in industries such as oil and gas, chemical, pharmaceutical, and aerospace. These discs are favored for their durability, corrosion resistance, and ability to withstand extreme temperatures, making them suitable for harsh environments. The market is characterized by technological advancements aimed at improving the performance and reliability of rupture discs. Manufacturers are focusing on developing discs with precise burst pressures and enhanced longevity to meet the stringent safety standards of various industries. The global market for stainless steel rupture discs was valued at approximately US$ 95 million in 2023 and is projected to grow to US$ 121 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This growth is indicative of the increasing emphasis on safety and regulatory compliance across industries worldwide.

Positive Arch Rupture Discs, Anti-Arch Rupture Discs, Flat Type Rupture Discs in the Stainless Steel Rupture Discs - Global Market:

Positive arch rupture discs, anti-arch rupture discs, and flat type rupture discs are specific types of stainless steel rupture discs, each designed to cater to different operational requirements and pressure conditions. Positive arch rupture discs are characterized by their convex shape, which allows them to handle higher pressures and provide a quick response to overpressure situations. These discs are typically used in applications where rapid pressure relief is crucial, such as in the oil and gas industry. The convex design ensures that the disc bursts outward, minimizing the risk of damage to surrounding equipment. Anti-arch rupture discs, on the other hand, feature a concave design that allows them to withstand vacuum conditions and back pressure. This makes them suitable for applications in the chemical and pharmaceutical industries, where processes may involve fluctuating pressures and the need for vacuum resistance. The concave shape ensures that the disc bursts inward, providing reliable pressure relief without compromising the integrity of the system. Flat type rupture discs are designed with a flat surface, offering a cost-effective solution for applications with moderate pressure requirements. These discs are commonly used in industries where cost considerations are paramount, and the pressure conditions are relatively stable. The flat design provides a straightforward and reliable means of pressure relief, making them a popular choice for general industrial applications. Each type of rupture disc is engineered to meet specific safety and operational needs, ensuring that industries can select the most appropriate solution for their unique pressure management challenges. The global market for these rupture discs is driven by the diverse needs of industries seeking reliable and efficient pressure relief solutions. As industries continue to prioritize safety and regulatory compliance, the demand for specialized rupture discs is expected to grow, further fueling innovation and development in this sector.

Oil and Gas, Chemical, Aerospace, Pharmaceutical, Others in the Stainless Steel Rupture Discs - Global Market:

Stainless steel rupture discs are widely used across various industries due to their reliability and effectiveness in preventing overpressure incidents. In the oil and gas industry, these discs play a crucial role in ensuring the safety of drilling operations, pipelines, and storage facilities. The harsh conditions and high-pressure environments typical of this industry necessitate the use of robust and durable rupture discs that can withstand extreme temperatures and corrosive substances. In the chemical industry, stainless steel rupture discs are essential for maintaining the integrity of reactors, storage tanks, and piping systems. The ability to handle a wide range of chemicals and withstand corrosive environments makes these discs a preferred choice for chemical manufacturers. In the aerospace industry, rupture discs are used in various applications, including fuel systems and hydraulic systems, where precise pressure management is critical to ensure the safety and performance of aircraft. The lightweight and high-strength properties of stainless steel make these discs ideal for aerospace applications. In the pharmaceutical industry, rupture discs are used to protect sensitive equipment and processes from overpressure, ensuring the safety and quality of pharmaceutical products. The need for sterile and contamination-free environments in pharmaceutical manufacturing further underscores the importance of reliable rupture discs. Additionally, stainless steel rupture discs find applications in other industries such as food and beverage, power generation, and water treatment, where they provide essential pressure relief solutions. The versatility and adaptability of stainless steel rupture discs make them an indispensable component in a wide range of industrial applications, contributing to the overall safety and efficiency of operations.

Stainless Steel Rupture Discs - Global Market Outlook:

The global market outlook for stainless steel rupture discs indicates a promising growth trajectory. In 2023, the market was valued at approximately US$ 95 million, and it is anticipated to expand to US$ 121 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for safety and regulatory compliance across various industries, including oil and gas, chemical, pharmaceutical, and aerospace. The North American market for stainless steel rupture discs is also expected to experience significant growth during this period, although specific figures for this region were not provided. The market expansion is attributed to the rising awareness of the importance of overpressure protection and the adoption of advanced rupture disc technologies. Manufacturers are focusing on developing innovative solutions that offer enhanced performance, reliability, and cost-effectiveness to meet the evolving needs of industries. As industries continue to prioritize safety and operational efficiency, the demand for stainless steel rupture discs is expected to rise, further driving market growth and development.

| Report Metric | Details |

| Report Name | Stainless Steel Rupture Discs - Market |

| Forecasted market size in 2030 | US$ 121 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BS&B Safety Systems, Continental Disc, Fike, V-TEX, Halma, REMBE, Dalian Duta Technology, Shanghai Hua Li Safety Device, Emerson, Mersen, ZOOK, Donadon SDD, SGL Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |