What is Global Outer Rotor Winding Machine Market?

The Global Outer Rotor Winding Machine Market is a specialized segment within the broader machinery industry, focusing on the production of machines designed to wind coils for outer rotor motors. These machines are essential in manufacturing motors used in various applications, including automotive, industrial, and consumer electronics. Outer rotor winding machines are engineered to handle the specific requirements of outer rotor motors, which differ from inner rotor motors in terms of design and functionality. The market for these machines is driven by the increasing demand for efficient and compact motor solutions across different industries. As industries continue to innovate and seek more energy-efficient solutions, the demand for outer rotor winding machines is expected to grow. These machines are crucial for ensuring the precision and quality of the winding process, which directly impacts the performance and efficiency of the motors they produce. The market is characterized by technological advancements, with manufacturers focusing on developing machines that offer higher precision, speed, and automation capabilities. This market is also influenced by the global push towards sustainability, as more industries look to reduce energy consumption and improve the efficiency of their products.

Fully Automatic, Semi-automatic, Manual in the Global Outer Rotor Winding Machine Market:

In the Global Outer Rotor Winding Machine Market, machines are categorized based on their level of automation: fully automatic, semi-automatic, and manual. Fully automatic winding machines are at the forefront of technological advancement in this market. These machines are designed to operate with minimal human intervention, offering high precision and efficiency. They are equipped with advanced features such as programmable logic controllers (PLCs), touch screen interfaces, and automated loading and unloading systems. Fully automatic machines are ideal for large-scale production environments where consistency and speed are critical. They reduce the likelihood of human error and can operate continuously, making them a preferred choice for manufacturers looking to optimize production and reduce labor costs. On the other hand, semi-automatic winding machines offer a balance between automation and manual operation. These machines require some level of human intervention, typically for tasks such as loading and unloading materials or adjusting machine settings. Semi-automatic machines are suitable for medium-scale production environments where flexibility and adaptability are important. They offer a cost-effective solution for manufacturers who need a certain level of automation but do not require the full capabilities of a fully automatic machine. Manual winding machines, while less common in large-scale industrial settings, still hold relevance in the market. These machines rely heavily on human operation and are typically used in small-scale production or specialized applications where precision and customization are more important than speed. Manual machines offer the highest level of control over the winding process, allowing operators to make real-time adjustments and ensure the highest quality of the final product. They are often used in research and development settings or for producing prototypes and custom motor designs. Each type of machine has its own set of advantages and is chosen based on the specific needs of the manufacturer, the scale of production, and the level of precision required. As the market continues to evolve, manufacturers are increasingly looking for machines that offer a combination of speed, precision, and flexibility to meet the diverse needs of their customers.

Automotive, Electrical, Others in the Global Outer Rotor Winding Machine Market:

The Global Outer Rotor Winding Machine Market finds its applications across various industries, with significant usage in the automotive, electrical, and other sectors. In the automotive industry, outer rotor winding machines are crucial for producing motors used in electric vehicles (EVs) and hybrid vehicles. As the automotive industry shifts towards more sustainable and energy-efficient solutions, the demand for high-performance motors has increased. Outer rotor motors, known for their compact design and high torque output, are ideal for automotive applications. Winding machines ensure that these motors are produced with the precision and efficiency required to meet the stringent performance standards of the automotive industry. In the electrical sector, outer rotor winding machines are used to manufacture motors for a wide range of applications, including household appliances, industrial machinery, and power tools. The demand for energy-efficient and reliable motors in these applications drives the need for high-quality winding machines. These machines play a critical role in ensuring that the motors are wound with the precision necessary to achieve optimal performance and energy efficiency. The electrical industry is constantly evolving, with new technologies and applications emerging, further driving the demand for advanced winding machines. Beyond automotive and electrical applications, outer rotor winding machines are also used in other industries such as aerospace, healthcare, and consumer electronics. In the aerospace industry, these machines are used to produce motors for various applications, including aircraft systems and unmanned aerial vehicles (UAVs). The healthcare industry utilizes outer rotor motors in medical devices and equipment, where precision and reliability are paramount. In consumer electronics, outer rotor motors are used in products such as drones, cameras, and personal care devices. The versatility and adaptability of outer rotor winding machines make them an essential tool for manufacturers across these diverse industries. As technology continues to advance and industries seek more efficient and sustainable solutions, the demand for outer rotor winding machines is expected to grow, further solidifying their importance in the global market.

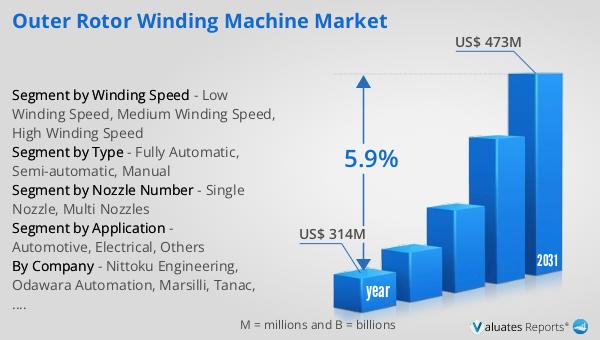

Global Outer Rotor Winding Machine Market Outlook:

The global market for Outer Rotor Winding Machines was valued at approximately $314 million in 2024. This market is anticipated to expand significantly, reaching an estimated value of $473 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.9% over the forecast period. This upward trend is indicative of the increasing demand for outer rotor winding machines across various industries, driven by the need for efficient and high-performance motor solutions. The market's expansion is fueled by technological advancements in winding machine design and functionality, as well as the growing emphasis on energy efficiency and sustainability. As industries continue to innovate and seek more efficient solutions, the demand for outer rotor winding machines is expected to rise. This growth is also supported by the increasing adoption of electric vehicles and the need for advanced motor technologies in the automotive sector. The market's positive outlook reflects the ongoing efforts of manufacturers to develop machines that offer higher precision, speed, and automation capabilities, meeting the diverse needs of their customers. As the market continues to evolve, it is poised to play a crucial role in the global machinery industry, providing essential solutions for a wide range of applications.

| Report Metric | Details |

| Report Name | Outer Rotor Winding Machine Market |

| Accounted market size in year | US$ 314 million |

| Forecasted market size in 2031 | US$ 473 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Winding Speed |

|

| Segment by Nozzle Number |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nittoku Engineering, Odawara Automation, Marsilli, Tanac, Bestec, Acme Mechatronics, Jinkang Precision Mechanism, Whitelegg Machines, Synthesis, DETZO, Broomfield, Winding Automatio, Meteor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |