What is Electrodeposited Copper Foils for Electronics - Global Market?

Electrodeposited copper foils are a crucial component in the electronics industry, serving as a fundamental material for various electronic applications. These foils are created through an electrochemical process where copper ions are deposited onto a rotating drum, forming a thin, uniform layer of copper. This method allows for precise control over the thickness and quality of the copper foil, making it ideal for use in high-performance electronic devices. The global market for electrodeposited copper foils is driven by the increasing demand for electronic devices, such as smartphones, tablets, and laptops, which require high-quality copper foils for their printed circuit boards (PCBs). Additionally, the rise of electric vehicles and renewable energy technologies has further fueled the demand for these foils, as they are essential for the production of batteries and other energy storage devices. The market is characterized by a diverse range of applications, including PCBs, electromagnetic interference (EMI) shielding, batteries, and switchgear, among others. As technology continues to advance, the demand for electrodeposited copper foils is expected to grow, driven by the need for more efficient and reliable electronic components.

Thickness: <20 μm, Thickness: 20-50 μm, Thickness: >50 μm in the Electrodeposited Copper Foils for Electronics - Global Market:

Electrodeposited copper foils are available in various thicknesses, each serving different applications and requirements in the electronics industry. Foils with a thickness of less than 20 μm are typically used in applications where lightweight and high flexibility are essential. These ultra-thin foils are ideal for flexible printed circuit boards (FPCBs) and other applications where space is limited, such as in smartphones and wearable devices. The thinness of these foils allows for the creation of compact and lightweight electronic devices without compromising on performance. On the other hand, foils with a thickness ranging from 20 to 50 μm are commonly used in standard PCBs, which are found in a wide range of electronic devices, from consumer electronics to industrial equipment. These foils provide a good balance between flexibility and durability, making them suitable for applications that require reliable electrical conductivity and mechanical strength. Finally, foils with a thickness greater than 50 μm are used in applications that demand high current carrying capacity and enhanced mechanical properties. These thicker foils are often used in power electronics, such as inverters and converters, where they provide the necessary strength and conductivity to handle high power levels. The choice of foil thickness depends on the specific requirements of the application, with each thickness offering unique advantages in terms of performance and functionality. As the demand for advanced electronic devices continues to grow, the market for electrodeposited copper foils of varying thicknesses is expected to expand, driven by the need for more efficient and reliable electronic components.

Printed Circuit Boards, EMI Shielding, Batteries, Switchgear, Others in the Electrodeposited Copper Foils for Electronics - Global Market:

Electrodeposited copper foils play a vital role in various electronic applications, each with its unique requirements and benefits. In printed circuit boards (PCBs), these foils serve as the conductive layer that connects different components, enabling the flow of electrical signals throughout the board. The high conductivity and reliability of electrodeposited copper foils make them ideal for use in PCBs, ensuring efficient performance and longevity of electronic devices. In electromagnetic interference (EMI) shielding, copper foils are used to protect sensitive electronic components from external electromagnetic fields, which can cause interference and degrade performance. The excellent shielding properties of copper make it an effective material for preventing EMI, ensuring the smooth operation of electronic devices. In batteries, electrodeposited copper foils are used as current collectors, providing a conductive pathway for the flow of electrons between the anode and cathode. The high conductivity and corrosion resistance of copper make it an ideal material for this application, ensuring efficient energy storage and delivery. In switchgear, copper foils are used to create conductive pathways for the flow of electrical current, ensuring reliable operation and safety of electrical systems. The durability and conductivity of copper make it a preferred choice for switchgear applications, where high performance and reliability are essential. Other applications of electrodeposited copper foils include flexible electronics, where their flexibility and conductivity are leveraged to create innovative and compact electronic devices. As technology continues to evolve, the demand for electrodeposited copper foils in these and other applications is expected to grow, driven by the need for more efficient and reliable electronic components.

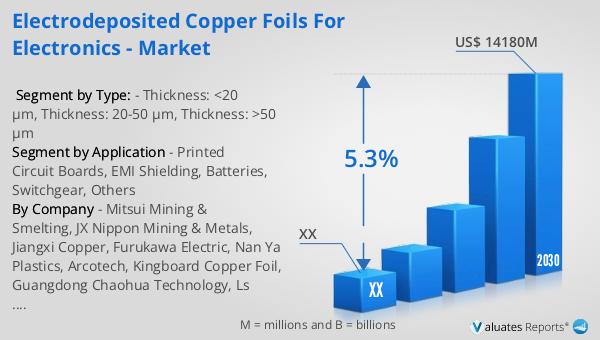

Electrodeposited Copper Foils for Electronics - Global Market Outlook:

The global market for electrodeposited copper foils for electronics was valued at approximately $9,807 million in 2023. It is projected to grow to a revised size of $14,180 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality copper foils in various electronic applications, including printed circuit boards, batteries, and EMI shielding. The North American market for electrodeposited copper foils was valued at $ million in 2023 and is expected to reach $ million by 2030, with a CAGR of % during the forecast period. This growth is attributed to the rising demand for advanced electronic devices and the increasing adoption of electric vehicles and renewable energy technologies in the region. The market is characterized by a diverse range of applications, each with its unique requirements and benefits, driving the demand for electrodeposited copper foils in various thicknesses and configurations. As technology continues to advance, the market for electrodeposited copper foils is expected to expand, driven by the need for more efficient and reliable electronic components.

| Report Metric | Details |

| Report Name | Electrodeposited Copper Foils for Electronics - Market |

| Forecasted market size in 2030 | US$ 14180 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mitsui Mining & Smelting, JX Nippon Mining & Metals, Jiangxi Copper, Furukawa Electric, Nan Ya Plastics, Arcotech, Kingboard Copper Foil, Guangdong Chaohua Technology, Ls Mtron, Chang Chun Petrochemical, Minerex, Circuit Foil Luxembourg, Suzhou Fukuda Metal, LingBao Wason Copper Foil, Targray Technology International, Shandong Jinbao Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |