What is Global Vacuum Dry Box Market?

The Global Vacuum Dry Box Market refers to the industry focused on the production, distribution, and utilization of vacuum dry boxes. These specialized containers are designed to maintain a controlled environment by removing air and moisture, which is crucial for storing sensitive materials. Vacuum dry boxes are widely used in various sectors, including medical, laboratory, and electronics, to protect items from contamination, oxidation, and other environmental factors that could compromise their integrity. The market encompasses a range of products, from small benchtop units to large industrial systems, catering to different needs and applications. The demand for vacuum dry boxes is driven by the increasing need for high-quality storage solutions in industries that handle delicate and valuable materials. As technology advances and industries become more specialized, the importance of maintaining controlled environments continues to grow, making vacuum dry boxes an essential tool in many fields. The market is characterized by continuous innovation, with manufacturers striving to improve the efficiency, reliability, and user-friendliness of their products.

Automatic, Manual in the Global Vacuum Dry Box Market:

In the Global Vacuum Dry Box Market, products can be broadly categorized into automatic and manual types. Automatic vacuum dry boxes are equipped with advanced features that allow for precise control of the internal environment with minimal human intervention. These systems often include programmable settings, digital displays, and automated vacuum pumps that maintain the desired conditions consistently. They are ideal for applications that require stringent environmental control, such as in the semiconductor and pharmaceutical industries. The automation ensures that the internal conditions remain stable, reducing the risk of human error and enhancing the reliability of the storage process. On the other hand, manual vacuum dry boxes require more hands-on operation. Users must manually adjust the settings and monitor the conditions inside the box. While they may lack the sophisticated features of their automatic counterparts, manual vacuum dry boxes are often more affordable and can be sufficient for less demanding applications. They are commonly used in smaller laboratories or for personal use where the precision of an automatic system is not necessary. Both types of vacuum dry boxes play a crucial role in protecting sensitive materials from environmental factors. The choice between automatic and manual systems depends on the specific needs of the user, including the level of control required, budget constraints, and the nature of the materials being stored. As industries continue to evolve, the demand for both types of vacuum dry boxes is expected to grow, driven by the need for reliable and efficient storage solutions.

Medical, Laboratory, Electronic Product, Others in the Global Vacuum Dry Box Market:

The Global Vacuum Dry Box Market finds extensive usage across various sectors, including medical, laboratory, electronic products, and others. In the medical field, vacuum dry boxes are essential for storing pharmaceuticals, biological samples, and medical devices. These items are highly sensitive to moisture and contaminants, and maintaining a controlled environment is crucial to preserving their efficacy and safety. For instance, certain medications and vaccines require specific storage conditions to remain effective, and vacuum dry boxes provide the necessary protection. In laboratories, vacuum dry boxes are used to store chemicals, reagents, and samples that are sensitive to air and moisture. Researchers rely on these boxes to ensure the integrity of their experiments and prevent contamination. The ability to control the internal environment of the box allows for precise storage conditions, which is vital for reproducibility and accuracy in scientific research. In the electronics industry, vacuum dry boxes are used to store components such as semiconductors, circuit boards, and other electronic parts that are prone to oxidation and moisture damage. The controlled environment helps in extending the shelf life of these components and ensures their reliability when used in manufacturing processes. Other sectors that benefit from vacuum dry boxes include aerospace, automotive, and food industries. In aerospace and automotive, vacuum dry boxes are used to store sensitive parts and materials that require protection from environmental factors. In the food industry, they are used to store perishable items and ingredients that need to be kept dry and free from contaminants. Overall, the versatility and effectiveness of vacuum dry boxes make them indispensable in various fields, ensuring the safety, quality, and longevity of sensitive materials.

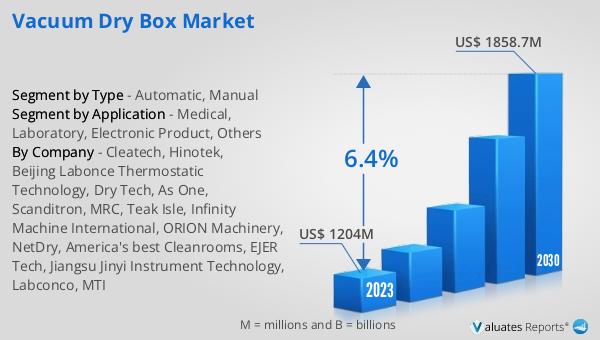

Global Vacuum Dry Box Market Outlook:

The global Vacuum Dry Box market was valued at US$ 1204 million in 2023 and is anticipated to reach US$ 1858.7 million by 2030, witnessing a CAGR of 6.4% during the forecast period 2024-2030. This significant growth reflects the increasing demand for reliable and efficient storage solutions across various industries. As the need for controlled environments becomes more critical, the market for vacuum dry boxes is expected to expand, driven by advancements in technology and the growing awareness of the importance of protecting sensitive materials. The market's robust growth trajectory underscores the essential role that vacuum dry boxes play in maintaining the integrity and quality of products in sectors such as medical, laboratory, and electronics. With continuous innovation and the development of more sophisticated and user-friendly products, the vacuum dry box market is poised to meet the evolving needs of its diverse customer base. The projected growth also highlights the market's potential for new entrants and existing players to capitalize on the increasing demand and expand their offerings to cater to a broader range of applications.

| Report Metric | Details |

| Report Name | Vacuum Dry Box Market |

| Accounted market size in 2023 | US$ 1204 million |

| Forecasted market size in 2030 | US$ 1858.7 million |

| CAGR | 6.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cleatech, Hinotek, Beijing Labonce Thermostatic Technology, Dry Tech, As One, Scanditron, MRC, Teak Isle, Infinity Machine International, ORION Machinery, NetDry, America's best Cleanrooms, EJER Tech, Jiangsu Jinyi Instrument Technology, Labconco, MTI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |