What is Sustained Release Film Coating - Global Market?

Sustained release film coating is a specialized technique used in the pharmaceutical industry to control the release rate of active ingredients in medications. This method involves applying a thin, uniform layer of polymer-based film onto the surface of tablets, capsules, or other dosage forms. The primary goal is to ensure that the drug is released at a predetermined rate, extending its therapeutic effect over a longer period. This not only improves patient compliance by reducing the frequency of dosing but also enhances the drug's efficacy and safety profile. The global market for sustained release film coatings is driven by the increasing demand for advanced drug delivery systems that offer better control over drug release and absorption. As pharmaceutical companies strive to develop more effective and patient-friendly medications, the adoption of sustained release technologies continues to grow. This market is characterized by ongoing research and development efforts aimed at improving the performance and versatility of film coating materials, as well as expanding their application across various therapeutic areas. The sustained release film coating market is poised for significant growth as it addresses the evolving needs of the pharmaceutical industry and contributes to the development of innovative drug delivery solutions.

Ethyl & methyl Cellulose, Polyvinyl & Cellulose acetate, Methacrylic Acid, PEG, Others in the Sustained Release Film Coating - Global Market:

Ethyl and methyl cellulose are two of the most commonly used polymers in the sustained release film coating market. These cellulose derivatives are favored for their excellent film-forming properties, which allow for the creation of a consistent and durable coating on pharmaceutical dosage forms. Ethyl cellulose, in particular, is known for its ability to form a water-insoluble barrier, making it ideal for controlling the release of water-soluble drugs. Methyl cellulose, on the other hand, is often used in combination with other polymers to achieve the desired release profile. Polyvinyl acetate is another important polymer in this market, valued for its flexibility and compatibility with a wide range of active pharmaceutical ingredients (APIs). It is often used in combination with other polymers to enhance the mechanical properties of the film coating and improve its adhesion to the substrate. Cellulose acetate is another cellulose derivative that is widely used in sustained release film coatings. It is known for its excellent film-forming properties and ability to create a semi-permeable barrier that controls the release of the drug. Methacrylic acid copolymers are also commonly used in sustained release film coatings. These polymers are known for their versatility and ability to form films with varying degrees of permeability, depending on the specific formulation. This allows for precise control over the release rate of the drug, making them ideal for use in a wide range of pharmaceutical applications. Polyethylene glycol (PEG) is often used as a plasticizer in sustained release film coatings. It helps to improve the flexibility and mechanical properties of the film, making it more resistant to cracking and peeling. PEG is also known for its ability to enhance the solubility of poorly water-soluble drugs, making it a valuable addition to many film coating formulations. Other materials used in sustained release film coatings include various types of waxes, fatty acids, and surfactants. These materials are often used to modify the release profile of the drug or to improve the overall performance of the film coating. The choice of materials used in a sustained release film coating formulation depends on a variety of factors, including the properties of the drug, the desired release profile, and the specific requirements of the dosage form. The sustained release film coating market is characterized by ongoing research and development efforts aimed at improving the performance and versatility of these materials. As pharmaceutical companies continue to seek out new and innovative ways to deliver drugs more effectively, the demand for advanced film coating technologies is expected to grow. This market is poised for significant growth as it addresses the evolving needs of the pharmaceutical industry and contributes to the development of innovative drug delivery solutions.

Tablets, Capsules, Pills in the Sustained Release Film Coating - Global Market:

Sustained release film coatings are widely used in the pharmaceutical industry to enhance the performance and efficacy of various dosage forms, including tablets, capsules, and pills. In the case of tablets, sustained release film coatings are applied to control the release rate of the active ingredient, ensuring that it is delivered at a consistent and predictable rate over an extended period. This not only improves patient compliance by reducing the frequency of dosing but also enhances the drug's therapeutic effect by maintaining a steady concentration of the active ingredient in the bloodstream. The use of sustained release film coatings in tablets is particularly beneficial for drugs with a narrow therapeutic window, as it helps to minimize fluctuations in drug levels and reduce the risk of side effects. Capsules are another common dosage form that benefits from sustained release film coatings. By applying a film coating to the surface of the capsule, pharmaceutical manufacturers can control the release rate of the active ingredient, ensuring that it is delivered at the desired rate and location within the gastrointestinal tract. This is particularly important for drugs that are sensitive to the acidic environment of the stomach or that require targeted delivery to specific regions of the intestine. Sustained release film coatings can also help to improve the stability and shelf life of capsules by providing a protective barrier against moisture and other environmental factors. Pills, like tablets and capsules, can also benefit from the application of sustained release film coatings. By controlling the release rate of the active ingredient, pharmaceutical manufacturers can ensure that the drug is delivered at a consistent and predictable rate, improving patient compliance and enhancing the drug's therapeutic effect. Sustained release film coatings can also help to mask the taste of bitter or unpleasant-tasting drugs, making them more palatable for patients. In addition to improving the performance and efficacy of these dosage forms, sustained release film coatings also offer several other benefits. They can help to reduce the risk of dose dumping, a phenomenon that occurs when a large amount of the active ingredient is released at once, leading to potentially dangerous spikes in drug levels. By controlling the release rate of the drug, sustained release film coatings can help to minimize the risk of dose dumping and improve the overall safety profile of the medication. Furthermore, sustained release film coatings can also help to improve the bioavailability of poorly water-soluble drugs by enhancing their solubility and dissolution rate. This can lead to improved absorption and therapeutic effect, making sustained release film coatings a valuable tool in the development of new and innovative drug delivery systems.

Sustained Release Film Coating - Global Market Outlook:

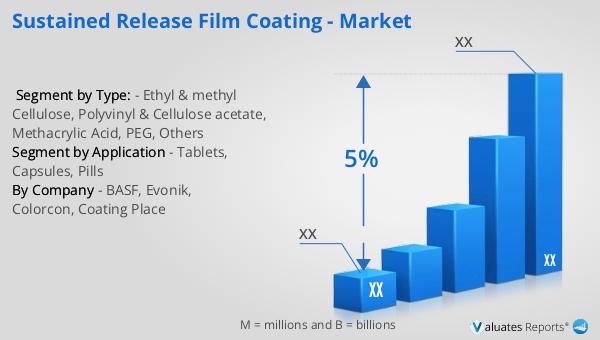

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, showcasing a steady growth trajectory with a compound annual growth rate (CAGR) of 5% projected over the next six years. This growth is indicative of the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, rising prevalence of chronic diseases, and advancements in drug development technologies. In comparison, the chemical drug market has also experienced growth, albeit at a slightly slower pace. It was estimated to have increased from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth reflects the ongoing demand for chemical-based medications, which continue to play a crucial role in the treatment of various medical conditions. The sustained release film coating market is an integral part of this broader pharmaceutical landscape, as it provides innovative solutions for drug delivery that enhance the efficacy and safety of medications. By enabling controlled release of active ingredients, sustained release film coatings contribute to improved patient compliance and therapeutic outcomes. As the pharmaceutical industry continues to evolve, the sustained release film coating market is expected to play a significant role in shaping the future of drug delivery systems.

| Report Metric | Details |

| Report Name | Sustained Release Film Coating - Market |

| CAGR | 5% |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | BASF, Evonik, Colorcon, Coating Place |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |