What is Industrial Temperature Sensor - Global Market?

Industrial temperature sensors are crucial components in various industries, providing accurate temperature measurements essential for maintaining optimal operational conditions. These sensors are designed to withstand harsh environments and deliver precise readings, ensuring the safety and efficiency of industrial processes. The global market for industrial temperature sensors is vast, driven by the increasing demand for automation and control systems across different sectors. These sensors are used in applications ranging from monitoring and controlling temperatures in manufacturing processes to ensuring the safety of equipment and personnel in hazardous environments. The market is characterized by a wide variety of sensor types, each tailored to specific industrial needs, including thermocouples, resistance temperature detectors (RTDs), thermistors, and infrared sensors. As industries continue to evolve and adopt more advanced technologies, the demand for reliable and accurate temperature sensors is expected to grow, further expanding the global market. The integration of temperature sensors with IoT and AI technologies is also opening new avenues for market growth, enabling real-time monitoring and predictive maintenance. This evolution is not only enhancing operational efficiency but also contributing to the sustainability efforts of industries worldwide.

Contact-Type Temperature Sensor, Noncontact-Type Temperature Sensor in the Industrial Temperature Sensor - Global Market:

Contact-type temperature sensors and noncontact-type temperature sensors are two primary categories within the industrial temperature sensor market, each serving distinct purposes and applications. Contact-type temperature sensors, such as thermocouples, RTDs, and thermistors, require direct contact with the object or medium whose temperature is being measured. Thermocouples are widely used due to their broad temperature range and durability, making them suitable for high-temperature applications in industries like metal processing and chemical manufacturing. They consist of two dissimilar metals joined at one end, creating a voltage that correlates with temperature changes. RTDs, on the other hand, offer high accuracy and stability, making them ideal for precision applications in industries such as pharmaceuticals and food processing. They operate on the principle that the resistance of a metal changes with temperature. Thermistors, known for their sensitivity, are often used in applications requiring rapid response times, such as HVAC systems and automotive temperature monitoring. Noncontact-type temperature sensors, such as infrared sensors and thermal imagers, measure temperature from a distance without direct contact. These sensors are particularly useful in situations where the object is moving, inaccessible, or too hot to touch. Infrared sensors detect the infrared radiation emitted by an object, converting it into a temperature reading. They are commonly used in applications like monitoring electrical equipment, detecting heat leaks in buildings, and ensuring the quality of products on production lines. Thermal imagers, a more advanced form of noncontact sensors, provide a visual representation of temperature distribution across a surface, enabling detailed analysis and troubleshooting. These are extensively used in predictive maintenance and quality control across various industries. Both contact and noncontact temperature sensors play vital roles in industrial settings, each offering unique advantages that cater to specific requirements. The choice between the two depends on factors such as the nature of the application, the required accuracy, and the environmental conditions. As technology advances, the capabilities of both sensor types continue to improve, offering enhanced performance and reliability. The integration of these sensors with digital systems and IoT platforms is further enhancing their functionality, providing industries with valuable insights into their processes and enabling more informed decision-making. This integration is driving the development of smart sensors that offer features like wireless connectivity, data logging, and remote monitoring, making them indispensable tools in modern industrial operations.

Oil & Gas, Food & Beverages, Healthcare, Automotive, Aerospace & Defense, Others in the Industrial Temperature Sensor - Global Market:

Industrial temperature sensors are employed across various sectors, each with unique requirements and challenges. In the oil and gas industry, these sensors are critical for monitoring and controlling temperatures in drilling operations, refineries, and pipelines. They ensure the safe and efficient operation of equipment, preventing overheating and potential hazards. Temperature sensors help maintain optimal conditions for chemical reactions and processes, contributing to the overall safety and productivity of the industry. In the food and beverages sector, temperature sensors are essential for ensuring product quality and safety. They are used in cooking, pasteurization, and refrigeration processes to maintain the required temperatures and prevent spoilage. Accurate temperature monitoring is crucial for compliance with food safety regulations and standards, ensuring that products are safe for consumption. In the healthcare industry, temperature sensors are vital for patient care and medical equipment. They are used in applications such as monitoring body temperature, controlling the temperature of incubators, and ensuring the proper storage of pharmaceuticals and vaccines. Accurate temperature measurements are essential for patient safety and the effectiveness of medical treatments. In the automotive industry, temperature sensors are used in engine management systems, climate control, and battery monitoring. They help optimize engine performance, improve fuel efficiency, and ensure passenger comfort. Temperature sensors also play a role in the development of electric vehicles, where they monitor battery temperatures to prevent overheating and extend battery life. In the aerospace and defense sector, temperature sensors are used in aircraft engines, environmental control systems, and missile guidance systems. They ensure the safe and efficient operation of equipment in extreme conditions, contributing to the reliability and performance of aerospace and defense systems. Other industries, such as manufacturing, energy, and telecommunications, also rely on temperature sensors for various applications, including process control, equipment monitoring, and environmental monitoring. The versatility and reliability of industrial temperature sensors make them indispensable tools in modern industrial operations, enabling industries to maintain optimal conditions, improve efficiency, and ensure safety. As industries continue to evolve and adopt more advanced technologies, the demand for reliable and accurate temperature sensors is expected to grow, further expanding the global market.

Industrial Temperature Sensor - Global Market Outlook:

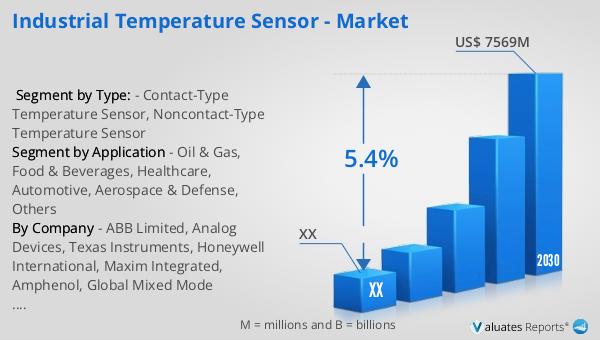

The global industrial temperature sensor market was valued at approximately $5,263 million in 2023, with projections indicating a growth to around $7,569 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. The North American segment of this market was also valued at a significant amount in 2023, with expectations of reaching a higher value by 2030, although specific figures for this region were not provided. The anticipated growth in the industrial temperature sensor market is driven by increasing demand across various industries, including oil and gas, food and beverages, healthcare, automotive, and aerospace and defense. These sectors require precise temperature monitoring to ensure safety, efficiency, and compliance with industry standards. The integration of temperature sensors with advanced technologies such as IoT and AI is further enhancing their capabilities, providing real-time data and predictive maintenance solutions. This technological advancement is expected to contribute significantly to market growth, as industries seek to improve operational efficiency and reduce downtime. The expanding applications of temperature sensors in emerging markets and the development of smart sensors with wireless connectivity and remote monitoring features are also expected to drive market growth. As industries continue to prioritize safety, efficiency, and sustainability, the demand for reliable and accurate temperature sensors is likely to increase, supporting the overall growth of the global industrial temperature sensor market.

| Report Metric | Details |

| Report Name | Industrial Temperature Sensor - Market |

| Forecasted market size in 2030 | US$ 7569 million |

| CAGR | 5.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ABB Limited, Analog Devices, Texas Instruments, Honeywell International, Maxim Integrated, Amphenol, Global Mixed Mode Technology, Integrated Device Technology, Kongsberg Gruppen, Microchip Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |