What is Skidding Systems - Global Market?

Skidding systems are specialized equipment used to move heavy loads horizontally. These systems are crucial in industries where large and heavy machinery or structures need to be relocated without the use of cranes or other lifting devices. The global market for skidding systems is driven by the demand for efficient and safe methods to transport heavy loads in various sectors such as construction, oil and gas, and manufacturing. Skidding systems typically consist of a series of tracks or rails and a hydraulic or mechanical system that pushes or pulls the load along these tracks. They are designed to handle extreme weights and are often used in environments where traditional lifting methods are impractical or unsafe. The versatility and efficiency of skidding systems make them an essential tool in modern industrial operations, contributing to their growing market presence worldwide. As industries continue to expand and the need for heavy load transportation increases, the demand for advanced skidding systems is expected to rise, further driving market growth.

Lightweight systems, Standard systems in the Skidding Systems - Global Market:

Lightweight and standard skidding systems are two primary categories within the global skidding systems market, each serving distinct purposes based on the specific needs of various industries. Lightweight skidding systems are designed for applications where the loads are not excessively heavy, but precision and ease of movement are still required. These systems are often used in industries such as electronics, pharmaceuticals, and small-scale manufacturing, where the equipment or products being moved are relatively lighter. The advantage of lightweight skidding systems lies in their portability and ease of setup, making them ideal for environments where space is limited or where the skidding system needs to be frequently relocated. They are typically constructed from materials like aluminum or high-strength plastics, which provide the necessary durability without adding excessive weight. On the other hand, standard skidding systems are built to handle much heavier loads and are commonly used in industries such as construction, oil and gas, and heavy manufacturing. These systems are designed to withstand the rigors of moving large machinery, structural components, and other substantial items. Standard skidding systems are often made from steel or other heavy-duty materials to ensure they can support the significant weights involved. They are equipped with powerful hydraulic systems that provide the necessary force to move these heavy loads safely and efficiently. The choice between lightweight and standard skidding systems depends largely on the specific requirements of the task at hand. For instance, in a manufacturing plant where large machinery needs to be repositioned regularly, a standard skidding system would be more appropriate due to its ability to handle the weight and size of the equipment. Conversely, in a laboratory setting where delicate instruments need to be moved, a lightweight skidding system would be more suitable due to its precision and ease of use. Both types of skidding systems play a crucial role in enhancing operational efficiency and safety across various industries. By providing a reliable method for moving heavy or cumbersome loads, they help reduce the risk of injury to workers and damage to equipment. As industries continue to evolve and the demand for efficient load-moving solutions grows, the market for both lightweight and standard skidding systems is expected to expand. This growth is driven by technological advancements that improve the performance and versatility of these systems, making them even more indispensable in modern industrial operations.

Offshore energy & Global infrastructure, Residential, Food & beverages, Chemical industries, Others in the Skidding Systems - Global Market:

Skidding systems are utilized across a wide range of industries, each with its unique requirements and challenges. In the offshore energy sector, skidding systems are essential for the installation and maintenance of heavy equipment such as drilling rigs and subsea structures. The harsh and often unpredictable conditions of offshore environments make traditional lifting methods impractical, and skidding systems provide a safe and efficient alternative. These systems are designed to withstand the corrosive effects of saltwater and the extreme pressures found at sea, ensuring reliable performance even in the most demanding conditions. In the global infrastructure sector, skidding systems are used for the construction and maintenance of large-scale projects such as bridges, tunnels, and skyscrapers. The ability to move heavy structural components with precision is crucial in these projects, and skidding systems provide the necessary control and stability. In residential construction, skidding systems are used for tasks such as moving prefabricated modules or large building materials. Their ability to maneuver in tight spaces and on uneven terrain makes them invaluable in urban environments where space is at a premium. In the food and beverage industry, skidding systems are used to move large processing equipment and storage tanks. The need for hygiene and cleanliness in these environments means that skidding systems must be easy to clean and maintain, and many are constructed from stainless steel or other non-corrosive materials. In the chemical industry, skidding systems are used to transport large reactors, distillation columns, and other heavy equipment. The hazardous nature of many chemical processes means that skidding systems must be designed to operate safely in potentially explosive environments. This often involves the use of specialized materials and components that can withstand high temperatures and corrosive substances. Beyond these specific industries, skidding systems are also used in a variety of other applications, from moving large artworks in museums to relocating heavy machinery in manufacturing plants. Their versatility and reliability make them an essential tool in any situation where heavy loads need to be moved with precision and care. As industries continue to grow and evolve, the demand for skidding systems is expected to increase, driving further innovation and development in this field.

Skidding Systems - Global Market Outlook:

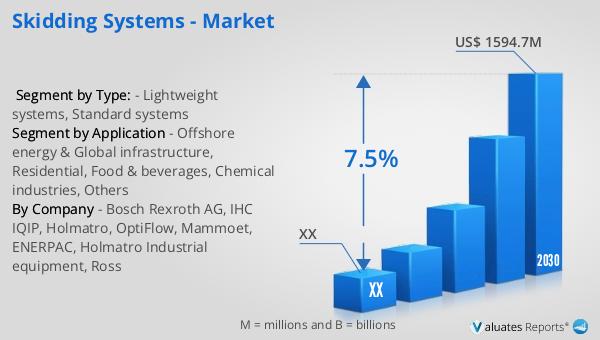

The global skidding systems market was valued at approximately $963 million in 2023 and is projected to grow significantly, reaching an estimated $1,594.7 million by 2030. This growth represents a compound annual growth rate (CAGR) of 7.5% during the forecast period from 2024 to 2030. This upward trend is indicative of the increasing demand for efficient and reliable methods of moving heavy loads across various industries. In North America, the skidding systems market is also expected to experience substantial growth, although specific figures for this region were not provided. The growth in this market can be attributed to the expanding industrial and construction sectors, which require advanced solutions for transporting heavy equipment and materials. The adoption of skidding systems in North America is driven by the need for improved safety and efficiency in load-moving operations, as well as the ongoing development of infrastructure projects. As industries continue to evolve and the demand for heavy load transportation solutions increases, the skidding systems market is poised for continued expansion. This growth is supported by technological advancements that enhance the performance and versatility of skidding systems, making them an indispensable tool in modern industrial operations.

| Report Metric | Details |

| Report Name | Skidding Systems - Market |

| Forecasted market size in 2030 | US$ 1594.7 million |

| CAGR | 7.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Bosch Rexroth AG, IHC IQIP, Holmatro, OptiFlow, Mammoet, ENERPAC, Holmatro Industrial equipment, Ross |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |