What is Global Flatbed Cutter Market?

The Global Flatbed Cutter Market refers to the industry focused on the production and sales of flatbed cutters, which are versatile cutting machines used to cut various materials such as paper, cardboard, textiles, and plastics. These machines are essential in industries like packaging, printing, and textiles, where precision cutting is crucial. Flatbed cutters come in different sizes and configurations, catering to both small-scale operations and large industrial applications. They are known for their accuracy, efficiency, and ability to handle complex cutting tasks, making them indispensable in modern manufacturing processes. The market for flatbed cutters is driven by the increasing demand for customized packaging, the growth of the e-commerce sector, and advancements in cutting technology. As businesses seek to improve their production capabilities and reduce waste, the adoption of flatbed cutters is expected to rise, contributing to the market's growth.

Display Cutter, Non-display Cutter in the Global Flatbed Cutter Market:

Flatbed cutters can be broadly categorized into display cutters and non-display cutters based on their features and applications. Display cutters are equipped with advanced display screens that provide real-time feedback and control over the cutting process. These screens allow operators to monitor and adjust settings with ease, ensuring precision and efficiency. Display cutters are often used in high-end applications where accuracy and customization are paramount, such as in the production of intricate packaging designs, signage, and promotional materials. The display interface enhances user experience by providing intuitive controls and visual guidance, reducing the likelihood of errors and improving overall productivity. On the other hand, non-display cutters lack these advanced display features but are still highly effective in performing cutting tasks. They are typically more affordable and are used in applications where the cutting requirements are straightforward and do not necessitate real-time monitoring. Non-display cutters are commonly found in small to medium-sized businesses that require reliable cutting solutions without the added cost of advanced features. Both types of cutters play a crucial role in the global flatbed cutter market, catering to different segments based on their specific needs and budget constraints. The choice between display and non-display cutters depends on factors such as the complexity of the cutting tasks, the level of precision required, and the available budget. As technology continues to evolve, the distinction between display and non-display cutters may blur, with more affordable options incorporating basic display features to enhance functionality. However, the core difference will remain in the level of control and customization offered by the display interface. In summary, display cutters provide advanced control and precision for complex tasks, making them suitable for high-end applications, while non-display cutters offer reliable performance for more straightforward cutting needs at a lower cost. Both types are essential in meeting the diverse demands of the global flatbed cutter market.

Residential, Commercial, Industrial in the Global Flatbed Cutter Market:

The usage of flatbed cutters spans across residential, commercial, and industrial sectors, each with its unique requirements and applications. In residential settings, flatbed cutters are often used by hobbyists and small business owners for crafting, scrapbooking, and DIY projects. These machines enable users to create intricate designs and cut various materials with precision, enhancing the quality and creativity of their projects. The affordability and ease of use of residential flatbed cutters make them accessible to a wide range of users, from amateur crafters to professional artists. In commercial settings, flatbed cutters are indispensable tools in industries such as printing, packaging, and advertising. Businesses use these machines to produce high-quality packaging materials, promotional items, and signage. The ability to cut complex shapes and designs with accuracy ensures that the final products meet the desired standards and appeal to customers. Commercial flatbed cutters are designed to handle higher volumes of work and offer features such as automated feeding and cutting, which streamline the production process and reduce labor costs. In industrial settings, flatbed cutters are used in large-scale manufacturing processes where precision and efficiency are critical. Industries such as automotive, aerospace, and textiles rely on these machines to cut materials like leather, fabric, and composites with high accuracy. Industrial flatbed cutters are built to withstand heavy usage and are equipped with advanced features such as laser cutting, automated material handling, and real-time monitoring. These capabilities enable manufacturers to produce high-quality components and products while minimizing waste and optimizing production efficiency. The versatility of flatbed cutters makes them valuable assets in various sectors, allowing businesses to meet their specific cutting needs and improve their overall productivity.

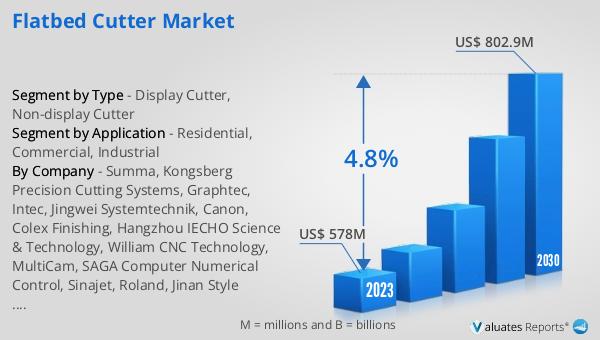

Global Flatbed Cutter Market Outlook:

The global flatbed cutter market was valued at $578 million in 2023 and is projected to reach $802.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. This growth is driven by several factors, including the increasing demand for customized packaging solutions, the expansion of the e-commerce sector, and technological advancements in cutting machinery. As businesses continue to seek ways to enhance their production capabilities and reduce operational costs, the adoption of flatbed cutters is expected to rise. These machines offer precision, efficiency, and versatility, making them essential tools in various industries such as printing, packaging, textiles, and manufacturing. The market's growth is also supported by the rising trend of automation in manufacturing processes, which flatbed cutters can facilitate through features like automated feeding and cutting. Additionally, the growing awareness of sustainable practices and the need to minimize material waste are encouraging businesses to invest in advanced cutting technologies that optimize resource usage. As a result, the global flatbed cutter market is poised for steady growth, driven by the continuous demand for high-quality, customized cutting solutions across different sectors.

| Report Metric | Details |

| Report Name | Flatbed Cutter Market |

| Accounted market size in 2023 | US$ 578 million |

| Forecasted market size in 2030 | US$ 802.9 million |

| CAGR | 4.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Summa, Kongsberg Precision Cutting Systems, Graphtec, Intec, Jingwei Systemtechnik, Canon, Colex Finishing, Hangzhou IECHO Science & Technology, William CNC Technology, MultiCam, SAGA Computer Numerical Control, Sinajet, Roland, Jinan Style Machinery, Advanced Plotting Devices |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |