What is Industrial Force Sensor - Global Market?

Industrial force sensors are crucial components in various industries, designed to measure forces such as tension, compression, and shear. These sensors are integral to ensuring precision and efficiency in industrial processes. The global market for industrial force sensors is expanding due to the increasing demand for automation and advanced manufacturing technologies. These sensors are used in applications ranging from robotics to automotive manufacturing, where precise force measurement is critical. The market is characterized by a diverse range of products, including load cells, strain gauges, and torque sensors, each tailored to specific applications. As industries continue to adopt smart manufacturing practices, the integration of force sensors into IoT systems is becoming more prevalent, enabling real-time data collection and analysis. This trend is driving innovation and growth in the market, as companies seek to enhance productivity and reduce operational costs. The global market for industrial force sensors is poised for significant growth, driven by technological advancements and the increasing need for precise force measurement in various industrial applications.

Analog, Digital in the Industrial Force Sensor - Global Market:

In the realm of industrial force sensors, the distinction between analog and digital technologies is pivotal. Analog force sensors operate by converting physical force into an electrical signal, which is then interpreted by the system. These sensors are known for their simplicity and reliability, often favored in applications where continuous monitoring is essential. Analog sensors provide a continuous output signal, which can be advantageous in applications requiring real-time feedback. However, they may be susceptible to signal degradation over long distances, which can affect accuracy. On the other hand, digital force sensors convert the physical force into a digital signal, offering several advantages over their analog counterparts. Digital sensors provide higher accuracy and are less prone to signal interference, making them ideal for applications requiring precise measurements. They also offer the benefit of easy integration with digital systems, facilitating data analysis and processing. The choice between analog and digital force sensors often depends on the specific requirements of the application, including factors such as accuracy, signal integrity, and integration capabilities. In the global market, there is a growing trend towards digital force sensors, driven by the increasing adoption of smart manufacturing technologies and the need for precise data collection and analysis. As industries continue to evolve, the demand for digital force sensors is expected to rise, as they offer enhanced performance and reliability in a wide range of applications. The global market for industrial force sensors is characterized by a diverse range of products, each tailored to specific applications and requirements. Load cells, for example, are commonly used in weighing applications, where precise force measurement is critical. Strain gauges, on the other hand, are often used in structural testing and monitoring, where they provide valuable data on stress and strain. Torque sensors are used in applications where rotational force needs to be measured, such as in automotive and aerospace industries. Each type of sensor offers unique advantages and is suited to specific applications, making the choice of sensor an important consideration in the design and implementation of industrial systems. As the global market for industrial force sensors continues to grow, companies are investing in research and development to create innovative products that meet the evolving needs of their customers. This includes the development of sensors with enhanced accuracy, reliability, and integration capabilities, as well as the incorporation of advanced technologies such as IoT and AI. These advancements are driving the growth of the market, as companies seek to enhance productivity and reduce operational costs through the use of advanced force measurement technologies. The global market for industrial force sensors is poised for significant growth, driven by technological advancements and the increasing need for precise force measurement in various industrial applications.

Manufacturing, Energy & Power, Pharmaceuticals, Chemicals, Oil & Gas, Mining, Others in the Industrial Force Sensor - Global Market:

Industrial force sensors play a crucial role in various sectors, including manufacturing, energy and power, pharmaceuticals, chemicals, oil and gas, and mining. In manufacturing, these sensors are used to ensure precision and quality control in production processes. They help in monitoring and controlling forces applied during assembly, welding, and machining operations, ensuring that products meet stringent quality standards. In the energy and power sector, force sensors are used in monitoring and controlling the forces in turbines, generators, and other equipment, ensuring efficient and safe operation. In the pharmaceutical industry, force sensors are used in tablet compression machines to ensure that tablets are produced with the correct hardness and weight. This is crucial for maintaining the efficacy and safety of pharmaceutical products. In the chemical industry, force sensors are used in various processes, including mixing, blending, and packaging, to ensure that products are produced with the correct specifications. In the oil and gas industry, force sensors are used in drilling and extraction operations to monitor and control the forces applied to equipment, ensuring safe and efficient operation. In the mining industry, force sensors are used in equipment such as crushers and conveyors to monitor and control the forces applied during material handling and processing. This helps in optimizing the efficiency and safety of mining operations. In addition to these industries, force sensors are also used in other sectors, including aerospace, automotive, and construction, where precise force measurement is critical for ensuring the safety and reliability of products and systems. The global market for industrial force sensors is driven by the increasing demand for precision and efficiency in various industries, as well as the growing adoption of smart manufacturing technologies. As industries continue to evolve, the demand for advanced force measurement solutions is expected to rise, driving the growth of the market.

Industrial Force Sensor - Global Market Outlook:

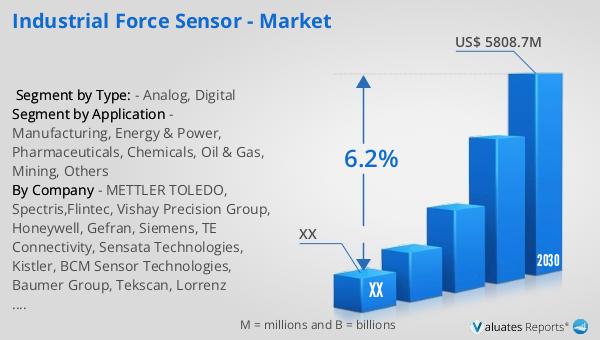

Industrial force sensors are highly suitable for measuring both dynamic and quasistatic forces, making them versatile tools in various applications. In 2023, the global market for industrial force sensors was valued at approximately $3,821 million. This market is projected to grow significantly, reaching an estimated size of $5,808.7 million by 2030, with a compound annual growth rate (CAGR) of 6.2% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for precise force measurement solutions across different industries. In North America, the market for industrial force sensors was valued at a substantial amount in 2023, and it is expected to continue its upward trajectory through 2030. The region's market growth is driven by the adoption of advanced manufacturing technologies and the need for precise force measurement in various applications. The CAGR for the North American market during the forecast period reflects the region's commitment to innovation and technological advancement. As industries continue to evolve and embrace smart manufacturing practices, the demand for industrial force sensors is expected to rise, contributing to the overall growth of the global market.

| Report Metric | Details |

| Report Name | Industrial Force Sensor - Market |

| Forecasted market size in 2030 | US$ 5808.7 million |

| CAGR | 6.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | METTLER TOLEDO, Spectris,Flintec, Vishay Precision Group, Honeywell, Gefran, Siemens, TE Connectivity, Sensata Technologies, Kistler, BCM Sensor Technologies, Baumer Group, Tekscan, Lorrenz Messtechnik gmbh, Futek Advanced Sensor Technology, Taiwan Alpha Electronic, Texas Instruments, ABB, Uneo, Priamus System Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |