What is Automobile Low-Frequency Sound-Absorbing Insulation - Global Market?

Automobile low-frequency sound-absorbing insulation is a specialized component in the automotive industry designed to reduce unwanted noise within vehicles. This type of insulation focuses on mitigating low-frequency sounds, which are often more challenging to control due to their longer wavelengths. These sounds can originate from various sources, such as the engine, road vibrations, and aerodynamic noise. By incorporating sound-absorbing materials, manufacturers aim to enhance the overall driving experience by providing a quieter cabin environment. The global market for this insulation is driven by the increasing demand for comfort and luxury in vehicles, as well as stringent regulations regarding noise pollution. As consumers become more discerning, the need for effective sound insulation solutions continues to grow. This market encompasses a range of materials and technologies, each offering unique benefits in terms of sound absorption, weight, and cost. Manufacturers are continually innovating to develop more efficient and sustainable solutions, catering to the diverse needs of the automotive industry. The market's growth is also influenced by the rising production of electric vehicles, which require specialized insulation to address the unique noise characteristics of electric drivetrains. Overall, the automobile low-frequency sound-absorbing insulation market plays a crucial role in enhancing vehicle comfort and meeting regulatory requirements.

Closed-cell Foams, Open-cell Foams in the Automobile Low-Frequency Sound-Absorbing Insulation - Global Market:

Closed-cell foams and open-cell foams are two primary types of materials used in automobile low-frequency sound-absorbing insulation. Closed-cell foams are characterized by their compact structure, where the cells are completely enclosed and not interconnected. This structure makes them highly effective at blocking sound transmission and providing thermal insulation. In the context of automobiles, closed-cell foams are often used in areas where moisture resistance and durability are critical, such as under the bonnet or in wheel wells. Their dense nature allows them to effectively dampen vibrations and reduce noise from the engine and road. Additionally, closed-cell foams are lightweight, which is a significant advantage in automotive applications where weight reduction is a priority for improving fuel efficiency. On the other hand, open-cell foams have a porous structure with interconnected cells, allowing air and sound waves to pass through. This makes them excellent at absorbing sound, particularly low-frequency noises. In vehicles, open-cell foams are commonly used in the interior, such as in door panels, headliners, and seats, to enhance acoustic comfort. Their ability to absorb sound rather than block it makes them ideal for reducing echoes and reverberations within the cabin. Open-cell foams are also more flexible and compressible, allowing them to conform to irregular shapes and surfaces, which is beneficial in automotive design. However, they are less effective at providing thermal insulation and are more susceptible to moisture absorption compared to closed-cell foams. The choice between closed-cell and open-cell foams in automobile sound-absorbing insulation depends on the specific requirements of the application. Manufacturers must consider factors such as the source and frequency of the noise, the desired level of sound reduction, and the environmental conditions the material will be exposed to. In some cases, a combination of both types of foams may be used to achieve optimal results. For instance, closed-cell foams might be used in areas prone to moisture exposure, while open-cell foams could be employed in the cabin to enhance acoustic comfort. The development of advanced foam materials continues to be a focus in the industry, with innovations aimed at improving performance, sustainability, and cost-effectiveness. As the demand for quieter and more comfortable vehicles grows, the role of closed-cell and open-cell foams in automobile low-frequency sound-absorbing insulation is expected to become increasingly important. Manufacturers are exploring new formulations and production techniques to enhance the sound-absorbing properties of these materials while minimizing their environmental impact. This includes the use of recycled materials and the development of foams with improved biodegradability. The global market for automobile low-frequency sound-absorbing insulation is poised for growth, driven by the increasing emphasis on vehicle comfort and the need to comply with noise regulations. As automotive technology continues to evolve, the demand for innovative sound-absorbing solutions will likely remain strong, with closed-cell and open-cell foams playing a pivotal role in meeting these challenges.

Under the Bonnet, Interior in the Automobile Low-Frequency Sound-Absorbing Insulation - Global Market:

The usage of automobile low-frequency sound-absorbing insulation is particularly significant in two key areas: under the bonnet and the vehicle interior. Under the bonnet, the primary source of noise is the engine, which generates a range of frequencies, including low-frequency sounds that can penetrate the cabin. To address this, manufacturers use sound-absorbing insulation materials that can withstand high temperatures and resist oil and other automotive fluids. Closed-cell foams are often preferred in this area due to their durability and moisture resistance. These materials help to dampen engine vibrations and reduce the transmission of noise into the cabin, contributing to a quieter driving experience. Additionally, sound-absorbing insulation under the bonnet can improve thermal management by reducing heat transfer from the engine to other parts of the vehicle. This dual functionality makes it an essential component in modern automotive design. In the vehicle interior, the focus is on creating a comfortable and quiet environment for passengers. Open-cell foams are commonly used in this context due to their excellent sound absorption properties. These materials are strategically placed in areas such as door panels, headliners, and seats to minimize noise from external sources and reduce echoes within the cabin. By absorbing sound waves, open-cell foams help to create a more pleasant acoustic environment, enhancing the overall driving experience. The use of sound-absorbing insulation in the interior is particularly important in electric vehicles, where the absence of engine noise can make other sounds, such as road and wind noise, more noticeable. By effectively managing these sounds, manufacturers can ensure that electric vehicles offer the same level of acoustic comfort as traditional vehicles. The integration of sound-absorbing insulation in both under the bonnet and interior areas is crucial for meeting consumer expectations and regulatory requirements. As vehicles become more sophisticated, with advanced infotainment systems and connectivity features, the need for effective sound management becomes even more critical. Manufacturers must balance the desire for a quiet cabin with other design considerations, such as weight reduction and cost efficiency. The development of innovative materials and technologies continues to drive advancements in this field, with a focus on improving performance and sustainability. As the global market for automobile low-frequency sound-absorbing insulation grows, the importance of these materials in enhancing vehicle comfort and meeting regulatory standards is expected to increase.

Automobile Low-Frequency Sound-Absorbing Insulation - Global Market Outlook:

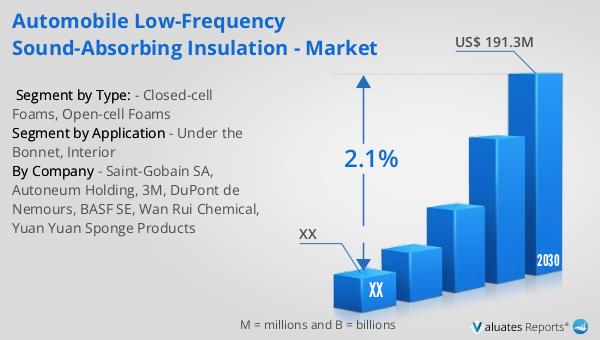

The global market for automobile low-frequency sound-absorbing insulation was valued at approximately $165 million in 2023. It is projected to expand to a revised size of $191.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.1% during the forecast period from 2024 to 2030. Currently, over 90% of the world's automobiles are concentrated in three major regions: Asia, Europe, and North America. Among these, Asia leads in automobile production, accounting for 56% of the global output. Europe follows with a 20% share, while North America contributes 16%. This distribution highlights the significant role these regions play in the automotive industry and, consequently, in the demand for sound-absorbing insulation. The growth of this market is driven by the increasing emphasis on vehicle comfort and the need to comply with noise regulations. As consumers continue to prioritize a quieter driving experience, the demand for effective sound insulation solutions is expected to rise. Manufacturers are focusing on developing innovative materials and technologies to meet these demands while also addressing environmental concerns. The market's expansion is further supported by the rising production of electric vehicles, which require specialized insulation to manage unique noise characteristics. Overall, the global market for automobile low-frequency sound-absorbing insulation is poised for steady growth, driven by the evolving needs of the automotive industry and the increasing importance of acoustic comfort.

| Report Metric | Details |

| Report Name | Automobile Low-Frequency Sound-Absorbing Insulation - Market |

| Forecasted market size in 2030 | US$ 191.3 million |

| CAGR | 2.1% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Saint-Gobain SA, Autoneum Holding, 3M, DuPont de Nemours, BASF SE, Wan Rui Chemical, Yuan Yuan Sponge Products |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |