What is Abrasion-resistive Coatings - Global Market?

Abrasion-resistive coatings are specialized protective layers applied to surfaces to enhance their durability and resistance to wear and tear. These coatings are crucial in industries where equipment and surfaces are subjected to harsh conditions, such as heavy machinery, automotive, aerospace, and construction. The global market for abrasion-resistive coatings is driven by the increasing demand for durable and long-lasting materials that can withstand extreme conditions. These coatings are designed to protect surfaces from mechanical damage, corrosion, and chemical exposure, thereby extending the lifespan of the equipment and reducing maintenance costs. The market is characterized by a wide range of products, including epoxy-based coatings, polyurethane coatings, and ceramic coatings, each offering unique properties and benefits. As industries continue to seek ways to improve efficiency and reduce operational costs, the demand for abrasion-resistive coatings is expected to grow, driven by advancements in coating technologies and the development of new materials that offer enhanced performance and sustainability.

Epoxy-based Coatings, Epoxy- and additive-based Coatings, Epoxy-based fast-curing Coatings, UV-curable hard Coatings in the Abrasion-resistive Coatings - Global Market:

Epoxy-based coatings are a popular choice in the abrasion-resistive coatings market due to their excellent adhesion, chemical resistance, and durability. These coatings are widely used in industrial applications where surfaces are exposed to harsh chemicals and mechanical stress. Epoxy-based coatings provide a tough, protective layer that can withstand heavy wear and tear, making them ideal for use in factories, warehouses, and other industrial settings. Epoxy- and additive-based coatings take the performance of traditional epoxy coatings to the next level by incorporating various additives that enhance their properties. These additives can improve the coating's flexibility, UV resistance, and impact resistance, making them suitable for a broader range of applications. Epoxy-based fast-curing coatings are designed for situations where quick turnaround times are essential. These coatings cure rapidly, allowing for faster application and reduced downtime, which is particularly beneficial in industries where time is of the essence. UV-curable hard coatings are another innovative solution in the abrasion-resistive coatings market. These coatings cure instantly when exposed to UV light, providing a hard, durable finish that is resistant to scratches and abrasion. UV-curable coatings are commonly used in the electronics and automotive industries, where precision and durability are critical. The global market for these coatings is expanding as industries continue to seek advanced solutions that offer superior protection and performance. The development of new formulations and technologies is driving innovation in the market, with manufacturers focusing on creating coatings that are not only effective but also environmentally friendly. As sustainability becomes a key consideration for businesses worldwide, the demand for eco-friendly coatings is expected to rise, further fueling the growth of the abrasion-resistive coatings market.

Surface Wearing/Abrasion, Extreme Corrosion/Erosion, Coarse Particle Abrasion, Fine Particle Abrasion, Other in the Abrasion-resistive Coatings - Global Market:

Abrasion-resistive coatings play a vital role in protecting surfaces from various forms of wear and tear, ensuring their longevity and performance. In the context of surface wearing or abrasion, these coatings provide a robust barrier that prevents the degradation of surfaces subjected to constant friction and mechanical stress. This is particularly important in industries such as mining, construction, and manufacturing, where equipment and surfaces are regularly exposed to abrasive materials. In extreme corrosion or erosion scenarios, abrasion-resistive coatings offer a protective layer that shields surfaces from chemical attacks and environmental factors that can lead to corrosion. These coatings are essential in industries like oil and gas, marine, and chemical processing, where equipment is exposed to harsh environments. Coarse particle abrasion involves the impact of large, abrasive particles on surfaces, which can cause significant damage over time. Abrasion-resistive coatings provide a tough, resilient surface that can withstand the impact of these particles, reducing wear and extending the lifespan of the equipment. Fine particle abrasion, on the other hand, involves the wear caused by smaller particles, which can penetrate and damage surfaces over time. These coatings offer a smooth, protective layer that prevents the ingress of fine particles, maintaining the integrity of the surface. In addition to these specific applications, abrasion-resistive coatings are also used in various other industries and applications where surface protection is critical. The versatility and effectiveness of these coatings make them an essential component in the maintenance and protection of industrial equipment and surfaces worldwide.

Abrasion-resistive Coatings - Global Market Outlook:

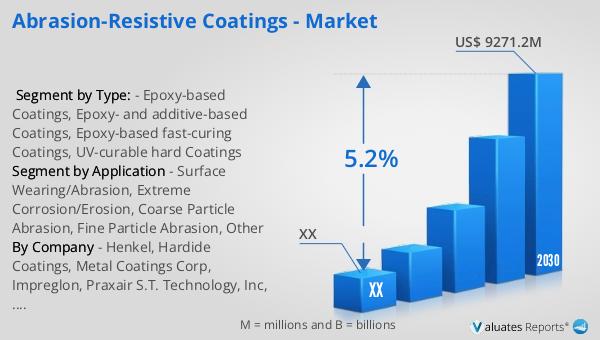

The global market for abrasion-resistive coatings was valued at approximately $6,523 million in 2023, with projections indicating a growth to around $9,271.2 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. The North American market, a significant segment of the global market, also shows promising growth potential. Although specific figures for the North American market in 2023 and 2030 are not provided, it is anticipated to follow a similar growth trajectory during the forecast period. The increasing demand for durable and long-lasting coatings across various industries is a key driver of this market growth. As industries continue to prioritize efficiency and cost-effectiveness, the adoption of abrasion-resistive coatings is expected to rise, contributing to the overall expansion of the market. The development of new technologies and materials that offer enhanced performance and sustainability is also expected to play a crucial role in shaping the future of the abrasion-resistive coatings market.

| Report Metric | Details |

| Report Name | Abrasion-resistive Coatings - Market |

| Forecasted market size in 2030 | US$ 9271.2 million |

| CAGR | 5.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, Hardide Coatings, Metal Coatings Corp, Impreglon, Praxair S.T. Technology, Inc, Jotun AS, Sika AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |