What is Abrasive Grade Boron Carbide - Global Market?

Abrasive grade boron carbide is a highly sought-after material in the global market due to its exceptional hardness and chemical stability. This compound, often referred to as a super abrasive, is primarily used in applications that require high durability and resistance to wear and tear. Boron carbide is one of the hardest materials available, ranking just below diamond and cubic boron nitride, which makes it ideal for abrasive applications. Its unique properties make it suitable for a variety of industrial uses, including grinding, polishing, and lapping. The global market for abrasive grade boron carbide is driven by its demand in industries such as aerospace, automotive, and electronics, where precision and durability are paramount. The market is characterized by a steady growth trajectory, fueled by technological advancements and the increasing need for high-performance materials in manufacturing processes. As industries continue to evolve and demand more efficient and durable materials, the role of abrasive grade boron carbide in the global market is expected to expand, offering new opportunities for innovation and application.

Powder, Paste, Grains in the Abrasive Grade Boron Carbide - Global Market:

Abrasive grade boron carbide is available in various forms, including powder, paste, and grains, each serving distinct purposes in the global market. The powder form of boron carbide is widely used in applications that require a fine abrasive material. It is often employed in the manufacturing of hard metals and ceramics, where it aids in the grinding and finishing processes. The fine particles of boron carbide powder provide a smooth finish and are ideal for precision applications. In the electronics industry, boron carbide powder is used for lapping and polishing semiconductor wafers, ensuring a high degree of flatness and surface quality. The paste form of boron carbide is typically used in applications that require a more controlled abrasive action. It is often used in the polishing of metals and ceramics, where it provides a consistent and uniform finish. The paste form is also used in the honing of engine components, where it helps achieve the desired surface texture and dimensional accuracy. Boron carbide paste is favored for its ease of application and ability to produce a high-quality finish. Grains of boron carbide are used in applications that require a more aggressive abrasive action. They are commonly used in sandblasting and water jet cutting, where they provide a powerful cutting force. The grains are also used in the production of abrasive wheels and belts, where they offer excellent wear resistance and durability. In the construction industry, boron carbide grains are used in the cutting and shaping of hard materials such as granite and marble. The versatility of boron carbide in its various forms makes it a valuable material in the global market, catering to a wide range of industrial applications. The demand for boron carbide in its different forms is driven by the need for high-performance materials that can withstand extreme conditions and deliver superior results. As industries continue to seek more efficient and durable materials, the role of boron carbide in the global market is expected to grow, offering new opportunities for innovation and application.

Grinding, Polishing, Others in the Abrasive Grade Boron Carbide - Global Market:

Abrasive grade boron carbide is extensively used in grinding, polishing, and other applications due to its exceptional hardness and durability. In grinding, boron carbide is used as an abrasive material to remove excess material from surfaces, achieving the desired shape and finish. Its hardness allows it to grind even the toughest materials, making it ideal for use in the manufacturing of hard metals and ceramics. Boron carbide grinding wheels and belts are commonly used in the aerospace and automotive industries, where precision and durability are critical. The ability of boron carbide to maintain its sharpness and resist wear makes it a preferred choice for grinding applications. In polishing, boron carbide is used to achieve a smooth and reflective surface finish. It is often used in the polishing of metals, ceramics, and glass, where it provides a high-quality finish. Boron carbide polishing compounds are used in the electronics industry for the finishing of semiconductor wafers, ensuring a high degree of flatness and surface quality. The consistent and uniform abrasive action of boron carbide makes it ideal for polishing applications that require a high level of precision. In addition to grinding and polishing, boron carbide is used in a variety of other applications. It is used in the production of armor and protective coatings, where its hardness and resistance to wear provide enhanced protection. Boron carbide is also used in the production of neutron absorbers for nuclear reactors, where its ability to absorb neutrons makes it an effective material for controlling nuclear reactions. The versatility of boron carbide in its various applications makes it a valuable material in the global market, catering to a wide range of industrial needs. The demand for boron carbide in its various applications is driven by the need for high-performance materials that can withstand extreme conditions and deliver superior results. As industries continue to seek more efficient and durable materials, the role of boron carbide in the global market is expected to grow, offering new opportunities for innovation and application.

Abrasive Grade Boron Carbide - Global Market Outlook:

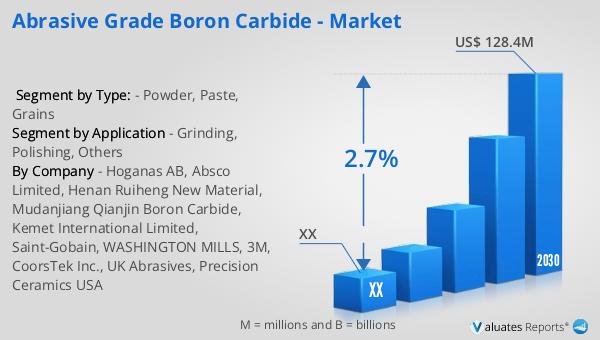

The global market for abrasive grade boron carbide was valued at approximately $106.8 million in 2023, with projections indicating a growth to around $128.4 million by 2030. This growth represents a compound annual growth rate (CAGR) of 2.7% over the forecast period from 2024 to 2030. The North American market for abrasive grade boron carbide also shows promising potential, although specific figures for 2023 and 2030 are not provided. The anticipated growth in this region is expected to align with the global trend, driven by increasing demand in various industrial sectors. The steady growth in the market is attributed to the rising need for high-performance materials in industries such as aerospace, automotive, and electronics. The unique properties of boron carbide, including its exceptional hardness and chemical stability, make it an ideal choice for applications that require durability and resistance to wear. As industries continue to evolve and demand more efficient and durable materials, the market for abrasive grade boron carbide is expected to expand, offering new opportunities for innovation and application. The forecasted growth in the market reflects the increasing recognition of boron carbide as a valuable material in the global market, catering to a wide range of industrial needs.

| Report Metric | Details |

| Report Name | Abrasive Grade Boron Carbide - Market |

| Forecasted market size in 2030 | US$ 128.4 million |

| CAGR | 2.7% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hoganas AB, Absco Limited, Henan Ruiheng New Material, Mudanjiang Qianjin Boron Carbide, Kemet International Limited, Saint-Gobain, WASHINGTON MILLS, 3M, CoorsTek Inc., UK Abrasives, Precision Ceramics USA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |