What is Highly Dispersible Silica - Global Market?

Highly dispersible silica (HDS) is a specialized form of silica that has gained significant attention in the global market due to its unique properties and wide range of applications. This type of silica is characterized by its ability to disperse uniformly in various matrices, which enhances the performance of the end products. HDS is primarily used in the rubber industry, particularly in the production of tires, where it improves fuel efficiency and reduces rolling resistance. The global market for highly dispersible silica is driven by the increasing demand for energy-efficient and environmentally friendly products. As industries strive to meet stringent environmental regulations and consumer demands for sustainable solutions, the adoption of HDS is expected to rise. The market is also influenced by advancements in technology and the development of new applications for HDS in various sectors. With its ability to enhance product performance and contribute to sustainability, highly dispersible silica is poised to play a crucial role in the future of several industries. The market dynamics are shaped by factors such as raw material availability, production costs, and the competitive landscape, which includes key players investing in research and development to innovate and expand their product offerings.

Form: Granular, Micropearl in the Highly Dispersible Silica - Global Market:

Highly dispersible silica is available in various forms, including granular and micropearl, each offering distinct advantages and applications in the global market. Granular HDS is typically used in applications where ease of handling and uniform distribution are critical. Its larger particle size compared to micropearl form allows for better flowability and mixing, making it suitable for bulk processing and large-scale industrial applications. Granular HDS is often preferred in the tire industry, where it is used to enhance the performance of rubber compounds by improving their mechanical properties and reducing rolling resistance. This form of silica is also used in the production of industrial rubber products, where its dispersibility and reinforcing capabilities contribute to the durability and longevity of the end products. On the other hand, micropearl HDS is characterized by its smaller particle size and higher surface area, which allows for more efficient interaction with other materials. This form is particularly advantageous in applications requiring high levels of dispersion and uniformity, such as in the production of high-performance rubber compounds and specialty coatings. Micropearl HDS is also used in the footwear industry, where it enhances the flexibility and comfort of shoe soles while maintaining their strength and durability. The choice between granular and micropearl forms of HDS depends on the specific requirements of the application, including factors such as processing conditions, desired product properties, and cost considerations. Manufacturers often tailor their HDS formulations to meet the unique needs of their customers, offering customized solutions that optimize performance and efficiency. The global market for highly dispersible silica is characterized by a diverse range of applications and a growing demand for innovative solutions that address the evolving needs of various industries. As the market continues to expand, the development of new forms and formulations of HDS is expected to drive further growth and open up new opportunities for manufacturers and end-users alike. The competitive landscape is marked by ongoing research and development efforts aimed at improving the properties and performance of HDS, as well as strategic partnerships and collaborations that foster innovation and drive market expansion. With its versatility and ability to enhance product performance, highly dispersible silica is set to remain a key component in the development of advanced materials and sustainable solutions across a wide range of industries.

Tires, Industrial Rubber Products, Footwear in the Highly Dispersible Silica - Global Market:

Highly dispersible silica plays a crucial role in several key industries, including tires, industrial rubber products, and footwear, due to its unique properties and ability to enhance product performance. In the tire industry, HDS is used to improve the rolling resistance and fuel efficiency of tires, which are critical factors in reducing energy consumption and emissions. By incorporating HDS into tire formulations, manufacturers can produce tires that offer better grip, longer tread life, and improved safety, all while meeting stringent environmental regulations. The use of HDS in tires also contributes to the development of low-resistance tires, which are increasingly in demand as consumers and industries seek more sustainable transportation solutions. In the realm of industrial rubber products, highly dispersible silica is valued for its reinforcing capabilities, which enhance the mechanical properties and durability of rubber compounds. This makes it an ideal choice for applications such as conveyor belts, hoses, and seals, where strength and longevity are paramount. The ability of HDS to disperse uniformly within rubber matrices ensures consistent performance and reliability, even under demanding conditions. In the footwear industry, HDS is used to improve the flexibility, comfort, and durability of shoe soles. By enhancing the dispersion of silica within the rubber compounds used in footwear, manufacturers can produce shoes that offer superior cushioning and support, while maintaining their structural integrity over time. This is particularly important in athletic and outdoor footwear, where performance and comfort are key selling points. The versatility of highly dispersible silica allows it to be tailored to meet the specific needs of each industry, providing customized solutions that optimize performance and efficiency. As the demand for high-performance and sustainable products continues to grow, the use of HDS in these industries is expected to increase, driving further innovation and development in the global market.

Highly Dispersible Silica - Global Market Outlook:

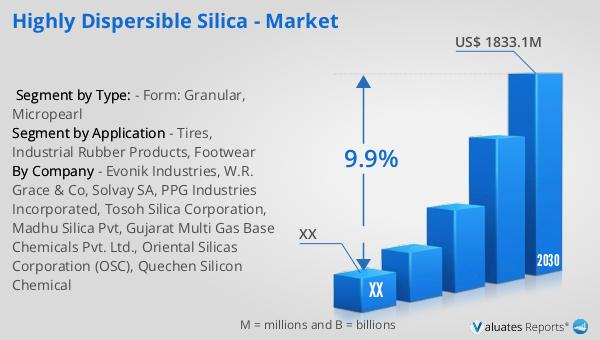

The global market for highly dispersible silica was valued at approximately $956 million in 2023 and is projected to reach an adjusted size of $1,833.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 9.9% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for HDS as a vital industrial raw material, influenced by various factors such as technological advancements, environmental regulations, and evolving consumer preferences. The market dynamics are shaped by the need for energy-efficient and sustainable solutions across multiple industries, including automotive, construction, and consumer goods. As industries strive to reduce their carbon footprint and enhance product performance, the adoption of highly dispersible silica is expected to rise. The competitive landscape is characterized by key players investing in research and development to innovate and expand their product offerings, as well as strategic partnerships and collaborations that foster market expansion. The future of the highly dispersible silica market is poised for significant growth, driven by its versatility and ability to enhance product performance across a wide range of applications. As the market continues to evolve, manufacturers and end-users alike are expected to benefit from the development of new forms and formulations of HDS, opening up new opportunities for innovation and growth.

| Report Metric | Details |

| Report Name | Highly Dispersible Silica - Market |

| Forecasted market size in 2030 | US$ 1833.1 million |

| CAGR | 9.9% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Evonik Industries, W.R. Grace & Co, Solvay SA, PPG Industries Incorporated, Tosoh Silica Corporation, Madhu Silica Pvt, Gujarat Multi Gas Base Chemicals Pvt. Ltd., Oriental Silicas Corporation (OSC), Quechen Silicon Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |