What is Catalyst for Polypropylene - Global Market?

Catalysts for polypropylene are crucial components in the production of polypropylene, a versatile plastic used in various industries. These catalysts facilitate the polymerization process, transforming propylene monomers into polypropylene polymers. The global market for these catalysts is driven by the increasing demand for polypropylene due to its wide range of applications, including packaging, automotive parts, textiles, and consumer goods. Polypropylene is favored for its lightweight, durable, and chemical-resistant properties, making it an essential material in manufacturing. The market is characterized by continuous advancements in catalyst technology, aiming to improve the efficiency and environmental sustainability of polypropylene production. Innovations in catalyst formulations are focused on enhancing polymer properties, reducing production costs, and minimizing environmental impact. The market is also influenced by regional production capacities, regulatory frameworks, and the availability of raw materials. As industries seek more sustainable and efficient production methods, the demand for advanced catalysts is expected to grow, driving further research and development in this field. The global market for polypropylene catalysts is competitive, with key players investing in technological advancements and strategic partnerships to maintain their market position.

Ziegler-Natta Catalyst, Metallocene Catalyst, Others in the Catalyst for Polypropylene - Global Market:

Ziegler-Natta catalysts are among the most widely used catalysts in the production of polypropylene. Developed in the 1950s, these catalysts revolutionized the polymer industry by enabling the production of stereoregular polymers, which have a uniform arrangement of molecular chains. This uniformity is crucial for achieving desirable mechanical properties in polypropylene, such as strength and flexibility. Ziegler-Natta catalysts are typically composed of transition metals like titanium, combined with organoaluminum compounds. They are highly effective in producing isotactic polypropylene, which is the most common form of polypropylene used in various applications. The efficiency of Ziegler-Natta catalysts has made them a staple in the industry, although they are gradually being supplemented by newer catalyst technologies. Metallocene catalysts represent a more recent advancement in polypropylene production. These catalysts consist of a metal center sandwiched between two cyclopentadienyl ligands, offering precise control over the polymerization process. This precision allows for the production of polypropylene with tailored properties, such as enhanced clarity, impact resistance, and elasticity. Metallocene catalysts are particularly valued for their ability to produce polymers with narrow molecular weight distributions, which can improve the performance of polypropylene in specific applications. Despite their higher cost compared to traditional Ziegler-Natta catalysts, metallocene catalysts are gaining popularity due to their superior performance characteristics. Other catalysts used in polypropylene production include post-metallocene catalysts and hybrid systems. Post-metallocene catalysts are designed to offer the benefits of metallocene catalysts while addressing some of their limitations, such as cost and processability. These catalysts often incorporate elements from both Ziegler-Natta and metallocene technologies, providing a balance between performance and cost-effectiveness. Hybrid catalyst systems combine different types of catalysts to optimize the polymerization process, allowing manufacturers to fine-tune the properties of polypropylene for specific applications. The choice of catalyst in polypropylene production depends on various factors, including the desired properties of the final product, production costs, and environmental considerations. As the demand for high-performance and sustainable polypropylene continues to grow, the development and adoption of advanced catalyst technologies are expected to play a crucial role in shaping the future of the global polypropylene market.

Films, Fibers, Tubes, Injection-molded Products, Others in the Catalyst for Polypropylene - Global Market:

Catalysts for polypropylene play a significant role in the production of various polypropylene-based products, including films, fibers, tubes, and injection-molded products. In the film industry, polypropylene is used to produce packaging films, agricultural films, and labeling films, among others. The use of catalysts in this sector is crucial for achieving the desired film properties, such as clarity, strength, and barrier performance. Advanced catalysts enable the production of films with enhanced mechanical and optical properties, making them suitable for demanding applications. In the fiber industry, polypropylene is used to produce nonwoven fabrics, carpets, and textiles. Catalysts are essential in this sector for controlling the molecular weight and distribution of polypropylene, which directly affects the strength, softness, and durability of the fibers. The development of catalysts that allow for the production of fine denier fibers has expanded the use of polypropylene in high-performance textile applications. In the production of tubes, polypropylene is valued for its chemical resistance and durability. Catalysts play a crucial role in ensuring the uniformity and consistency of the polymer, which is essential for producing high-quality tubes used in plumbing, irrigation, and industrial applications. The ability to produce polypropylene with specific properties, such as flexibility and impact resistance, is critical for meeting the diverse requirements of the tube industry. Injection-molded products represent another significant application area for polypropylene. This process involves injecting molten polypropylene into a mold to produce complex shapes and designs. Catalysts are vital in this process for controlling the flow properties and crystallinity of the polymer, which affects the final product's strength, appearance, and performance. The use of advanced catalysts allows manufacturers to produce injection-molded products with enhanced dimensional stability and surface finish, making them suitable for automotive, consumer goods, and electronics applications. Other applications of polypropylene catalysts include the production of foams, coatings, and adhesives. In these areas, catalysts are used to tailor the properties of polypropylene to meet specific performance requirements, such as thermal insulation, adhesion, and flexibility. The versatility of polypropylene, combined with the advancements in catalyst technology, continues to drive its use in a wide range of industries, making it a vital material in modern manufacturing.

Catalyst for Polypropylene - Global Market Outlook:

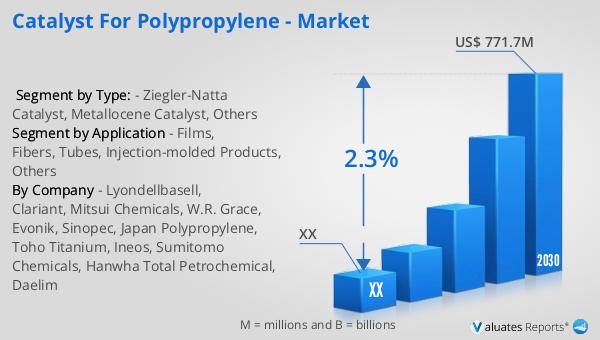

In 2023, the global market for catalysts used in polypropylene production was valued at approximately $655.9 million. This market is projected to grow, reaching an estimated size of $771.7 million by 2030, with a compound annual growth rate (CAGR) of 2.3% during the forecast period from 2024 to 2030. The market is dominated by major players such as LyondellBasell, W. R. Grace, Ineos, and Toho Titanium, with the top three companies collectively holding over 60% of the market share. Europe stands as the largest regional market, accounting for about 32% of the global market share, followed by North America, which holds approximately 27%. This growth is driven by the increasing demand for polypropylene in various applications, including packaging, automotive, and consumer goods. The market is characterized by continuous advancements in catalyst technology, aiming to improve the efficiency and environmental sustainability of polypropylene production. As industries seek more sustainable and efficient production methods, the demand for advanced catalysts is expected to grow, driving further research and development in this field. The global market for polypropylene catalysts is competitive, with key players investing in technological advancements and strategic partnerships to maintain their market position.

| Report Metric | Details |

| Report Name | Catalyst for Polypropylene - Market |

| Forecasted market size in 2030 | US$ 771.7 million |

| CAGR | 2.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Lyondellbasell, Clariant, Mitsui Chemicals, W.R. Grace, Evonik, Sinopec, Japan Polypropylene, Toho Titanium, Ineos, Sumitomo Chemicals, Hanwha Total Petrochemical, Daelim |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |