What is New Superalloy - Global Market?

New superalloys are advanced materials engineered to withstand extreme conditions, such as high temperatures and corrosive environments, making them indispensable in various high-performance applications. These alloys are primarily composed of nickel, cobalt, or iron, and are enhanced with additional elements like chromium, molybdenum, and titanium to improve their strength and durability. The global market for new superalloys is driven by the increasing demand from industries such as aerospace, power generation, and automotive, where components are subjected to intense heat and stress. As technology advances, the need for materials that can perform reliably under such conditions grows, propelling the development and adoption of these superalloys. The market is characterized by continuous innovation, with researchers and manufacturers striving to create alloys with superior properties to meet the evolving needs of various sectors. This dynamic landscape offers significant opportunities for growth, as industries seek to enhance the efficiency and longevity of their products through the use of these high-performance materials. The global market for new superalloys is poised for expansion, driven by technological advancements and the increasing demand for materials that can withstand the rigors of modern industrial applications.

Powder Superalloy, Intermetallic Compound, ODS alloy, High Temperature Metal Self - Moistening Materials, Other in the New Superalloy - Global Market:

Powder superalloys are a critical component of the new superalloy market, offering unique advantages in terms of manufacturing and performance. These alloys are produced using powder metallurgy, a process that allows for precise control over the composition and microstructure of the material. This method results in superalloys with enhanced mechanical properties, such as improved strength and resistance to thermal fatigue. Powder superalloys are particularly valuable in applications where complex shapes and fine details are required, as the powder metallurgy process allows for the creation of intricate components with minimal waste. Intermetallic compounds, another key segment of the new superalloy market, are materials composed of two or more metallic elements that form a distinct crystal structure. These compounds exhibit exceptional high-temperature strength and oxidation resistance, making them ideal for use in environments where conventional alloys would fail. Intermetallic compounds are often used in aerospace and power generation applications, where their ability to maintain structural integrity at elevated temperatures is crucial. ODS (oxide dispersion strengthened) alloys are a specialized type of superalloy that incorporates fine, stable oxide particles into the metal matrix. This dispersion of oxides enhances the alloy's high-temperature strength and creep resistance, making ODS alloys suitable for use in extreme environments such as gas turbines and nuclear reactors. The development of ODS alloys has been driven by the need for materials that can withstand prolonged exposure to high temperatures without losing their mechanical properties. High-temperature metal self-moistening materials represent an innovative approach to superalloy design, incorporating elements that promote the formation of a protective oxide layer on the surface of the material. This self-moistening capability enhances the alloy's resistance to oxidation and corrosion, extending its lifespan in harsh environments. These materials are particularly useful in applications where components are exposed to aggressive chemical environments, such as in chemical processing plants and marine applications. The new superalloy market also includes other advanced materials that offer unique properties and benefits. These materials are continually being developed and refined to meet the specific needs of various industries, ensuring that the market remains dynamic and responsive to technological advancements. As the demand for high-performance materials continues to grow, the new superalloy market is expected to expand, driven by the ongoing development of innovative materials and manufacturing processes.

Aero-Engine, Gas Turbine, Automobile, Industrial, Other in the New Superalloy - Global Market:

The usage of new superalloys in various sectors highlights their versatility and importance in modern industrial applications. In the aerospace industry, superalloys are essential for the production of aero-engine components, where they are used to manufacture turbine blades, discs, and other critical parts. These components must withstand extreme temperatures and pressures, making the high-temperature strength and oxidation resistance of superalloys invaluable. The use of superalloys in aero-engines enhances fuel efficiency and reduces emissions, contributing to the development of more sustainable aviation technologies. In the power generation sector, superalloys are used in gas turbines, where they play a crucial role in improving the efficiency and reliability of electricity production. The ability of superalloys to maintain their mechanical properties at high temperatures allows gas turbines to operate at higher temperatures, increasing their efficiency and reducing fuel consumption. This makes superalloys an essential component in the transition to cleaner and more efficient energy sources. In the automotive industry, superalloys are used in the production of turbochargers and exhaust systems, where their high-temperature strength and corrosion resistance are critical. The use of superalloys in these components helps improve engine performance and reduce emissions, supporting the development of more environmentally friendly vehicles. In industrial applications, superalloys are used in a wide range of equipment and machinery, where their durability and resistance to wear and corrosion are essential. These materials are used in the production of components for chemical processing, oil and gas exploration, and other demanding environments, where their ability to withstand harsh conditions ensures the reliability and longevity of industrial equipment. The versatility of superalloys also extends to other applications, such as medical devices and electronics, where their unique properties are leveraged to enhance performance and reliability. As industries continue to seek materials that can meet the demands of modern technology, the use of new superalloys is expected to grow, driven by their ability to deliver superior performance in challenging environments.

New Superalloy - Global Market Outlook:

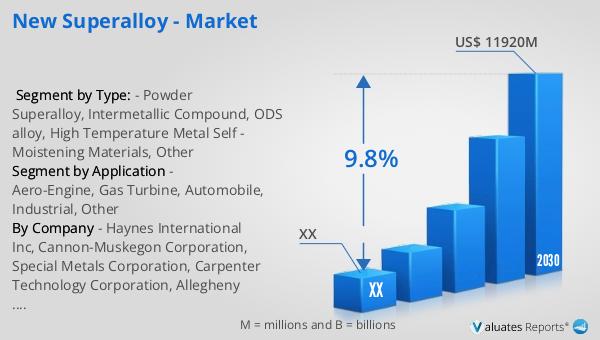

The market outlook for new superalloys indicates a promising future, driven by the diverse applications and technological advancements in this field. The analysis of this market primarily focuses on various types of superalloys, including powder superalloys, intermetallic compounds, ODS alloys, and high-temperature metal self-moistening materials. In 2023, the global market for new superalloys was valued at approximately US$ 6,231 million. This market is projected to grow significantly, reaching an estimated size of US$ 11,920 million by 2030. This growth represents a compound annual growth rate (CAGR) of 9.8% during the forecast period from 2024 to 2030. The increasing demand for high-performance materials in industries such as aerospace, power generation, and automotive is a key driver of this growth. As these industries continue to evolve and seek materials that can withstand extreme conditions, the demand for new superalloys is expected to rise. The market is also influenced by ongoing research and development efforts aimed at creating superalloys with enhanced properties and performance. This dynamic landscape offers significant opportunities for manufacturers and researchers to innovate and meet the evolving needs of various sectors. The future of the new superalloy market looks bright, with continued growth and development anticipated in the coming years.

| Report Metric | Details |

| Report Name | New Superalloy - Market |

| Forecasted market size in 2030 | US$ 11920 million |

| CAGR | 9.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Haynes International Inc, Cannon-Muskegon Corporation, Special Metals Corporation, Carpenter Technology Corporation, Allegheny Technologies Incorporated, General Electric, Pratt & Whitney, Rolls-Royce, Cisri-Gaona, Fushun Special Steel, Jiangsu ToLand Alloy, Western Superconducting Technologies, Wedge, Tokyo, NIPPON STEEL CORPORATION, JFE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |