What is Electrical Appliance Coating - Global Market?

Electrical appliance coating refers to the specialized coatings applied to various household and industrial appliances to enhance their durability, appearance, and functionality. These coatings are crucial in protecting appliances from wear and tear, corrosion, and environmental factors, thereby extending their lifespan. The global market for electrical appliance coatings is driven by the increasing demand for durable and aesthetically pleasing appliances. As consumers seek appliances that not only perform well but also complement their home decor, manufacturers are investing in advanced coating technologies. These coatings are typically applied to appliances like refrigerators, washing machines, microwaves, and air conditioners, among others. They come in various forms, including powder coatings, liquid coatings, and electroplated coatings, each offering unique benefits such as scratch resistance, heat resistance, and enhanced visual appeal. The market is also influenced by technological advancements and the growing trend of smart appliances, which require coatings that can accommodate electronic components and sensors. As a result, the electrical appliance coating market is poised for significant growth, driven by innovation and the evolving needs of consumers worldwide.

Plastics, Ceramics, Steel in the Electrical Appliance Coating - Global Market:

In the realm of electrical appliance coatings, materials such as plastics, ceramics, and steel play pivotal roles, each offering distinct advantages and applications. Plastics, for instance, are widely used due to their versatility and cost-effectiveness. They provide excellent insulation properties, making them ideal for coating electrical components within appliances. Plastic coatings are lightweight, resistant to moisture, and can be easily molded into various shapes, which is particularly beneficial for appliances with complex designs. Moreover, plastic coatings can be engineered to offer additional features like UV resistance and antimicrobial properties, enhancing the overall functionality of the appliance. On the other hand, ceramic coatings are renowned for their exceptional heat resistance and durability. These coatings are often used in appliances that operate at high temperatures, such as ovens and microwaves. Ceramic coatings provide a hard, protective layer that can withstand extreme heat without degrading, ensuring the appliance's longevity and safety. Additionally, ceramic coatings offer a smooth, non-stick surface, which is advantageous for cooking appliances as it facilitates easy cleaning and maintenance. Steel, particularly stainless steel, is another critical material in the electrical appliance coating market. Known for its strength and corrosion resistance, steel coatings are commonly applied to appliances exposed to moisture and harsh environments, such as washing machines and refrigerators. Steel coatings not only protect the appliance from rust and corrosion but also enhance its aesthetic appeal with a sleek, modern finish. Furthermore, steel coatings can be treated to improve their scratch resistance and antimicrobial properties, making them suitable for high-touch surfaces. The choice of coating material depends on various factors, including the appliance's intended use, environmental conditions, and consumer preferences. Manufacturers often combine different materials to achieve the desired balance of performance, durability, and aesthetics. As the demand for innovative and sustainable appliances grows, the development of advanced coating materials continues to evolve, offering new possibilities for enhancing appliance performance and consumer satisfaction.

Microwave Ovens, Coffee Machines, Washing Machines, Air Conditioners, Refrigerators, Vacuum Cleaners, Other in the Electrical Appliance Coating - Global Market:

Electrical appliance coatings play a crucial role in enhancing the performance and longevity of various household appliances, including microwave ovens, coffee machines, washing machines, air conditioners, refrigerators, vacuum cleaners, and others. In microwave ovens, coatings are essential for providing heat resistance and ensuring even heat distribution. Ceramic coatings, in particular, are favored for their ability to withstand high temperatures and prevent food from sticking to the interior surfaces, making cleaning easier. For coffee machines, coatings are used to protect internal components from moisture and heat, ensuring the machine's durability and consistent performance. Non-stick coatings are also applied to prevent coffee residue buildup, enhancing the machine's hygiene and ease of maintenance. Washing machines benefit from coatings that offer corrosion resistance and protection against harsh detergents and water exposure. Steel coatings are commonly used to prevent rust and extend the machine's lifespan, while plastic coatings provide insulation for electrical components. In air conditioners, coatings are crucial for protecting the unit from environmental factors such as humidity and dust. Anti-corrosion coatings are applied to the coils and other metal parts to ensure efficient cooling and prevent damage over time. Refrigerators rely on coatings to maintain energy efficiency and hygiene. Anti-bacterial coatings are often used on interior surfaces to prevent the growth of mold and bacteria, ensuring food safety. Additionally, coatings help in reducing energy consumption by improving the insulation properties of the refrigerator. Vacuum cleaners benefit from coatings that enhance their durability and resistance to wear and tear. Scratch-resistant coatings are applied to the exterior to maintain the appliance's appearance, while anti-static coatings prevent dust buildup on internal components. Other appliances, such as toasters and blenders, also utilize coatings to improve their performance and longevity. Non-stick coatings are applied to toaster surfaces to prevent bread from sticking, while blenders use coatings to protect blades and motor components from moisture and wear. Overall, electrical appliance coatings are integral to the functionality and durability of household appliances, offering protection against various environmental and operational challenges.

Electrical Appliance Coating - Global Market Outlook:

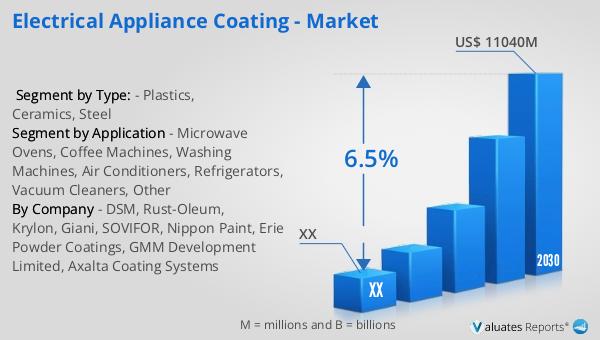

The global market for electrical appliance coatings was valued at approximately USD 7,123 million in 2023. This market is projected to experience significant growth, reaching an estimated size of USD 11,040 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030. The increasing demand for durable and aesthetically pleasing appliances is a key driver of this market expansion. As consumers continue to prioritize both functionality and design in their appliance choices, manufacturers are investing in advanced coating technologies to meet these expectations. The market's growth is also fueled by technological advancements and the rising trend of smart appliances, which require specialized coatings to accommodate electronic components and sensors. Additionally, the emphasis on sustainability and eco-friendly products is encouraging the development of coatings that are not only effective but also environmentally responsible. As a result, the electrical appliance coating market is poised for substantial growth, driven by innovation and the evolving needs of consumers worldwide. This positive market outlook highlights the significant opportunities for manufacturers and suppliers in the electrical appliance coating industry, as they strive to meet the increasing demand for high-quality, durable, and sustainable coatings.

| Report Metric | Details |

| Report Name | Electrical Appliance Coating - Market |

| Forecasted market size in 2030 | US$ 11040 million |

| CAGR | 6.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | DSM, Rust-Oleum, Krylon, Giani, SOVIFOR, Nippon Paint, Erie Powder Coatings, GMM Development Limited, Axalta Coating Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |