What is Industrial Level Sensor - Global Market?

Industrial level sensors are crucial components in various industries, providing accurate measurements of liquid or solid levels within containers, tanks, or silos. These sensors are essential for maintaining operational efficiency, safety, and automation in industrial processes. The global market for industrial level sensors is vast and diverse, encompassing a wide range of technologies and applications. These sensors are used in industries such as oil and gas, chemicals, pharmaceuticals, food and beverages, and water treatment, among others. They help in monitoring and controlling the levels of substances, ensuring that processes run smoothly and efficiently. The market is driven by the increasing demand for automation and the need for precise measurement and control in industrial processes. Technological advancements have led to the development of more sophisticated and reliable sensors, further boosting their adoption across various sectors. As industries continue to evolve and embrace new technologies, the demand for industrial level sensors is expected to grow, making it a dynamic and rapidly expanding market.

Contact, Non-contact in the Industrial Level Sensor - Global Market:

Industrial level sensors can be broadly categorized into contact and non-contact types, each with its own set of advantages and applications. Contact level sensors require physical contact with the substance being measured. They are typically used in applications where the medium is not corrosive or hazardous, and where direct contact does not affect the sensor's performance. Common types of contact level sensors include float switches, conductive sensors, and capacitive sensors. Float switches are simple devices that use a floating element to detect the level of a liquid. They are cost-effective and reliable for many applications. Conductive sensors, on the other hand, use electrical conductivity to detect the presence of a liquid. They are ideal for applications involving conductive liquids, such as water or certain chemicals. Capacitive sensors measure changes in capacitance caused by the presence of a liquid or solid material. They are versatile and can be used for both liquid and solid level detection. Non-contact level sensors, as the name suggests, do not require physical contact with the substance being measured. This makes them suitable for applications involving corrosive, hazardous, or sterile environments. Common types of non-contact level sensors include ultrasonic, radar, and laser sensors. Ultrasonic sensors use sound waves to measure the distance to the surface of a liquid or solid. They are widely used in applications where contact with the medium is not possible or desirable. Radar sensors, on the other hand, use radio waves to detect the level of a substance. They are highly accurate and can be used in challenging environments, such as those with high temperatures or pressures. Laser sensors use laser beams to measure the distance to the surface of a material. They are ideal for applications requiring high precision and accuracy. Both contact and non-contact level sensors have their own set of advantages and limitations. Contact sensors are generally more affordable and simpler to install and maintain. However, they may not be suitable for all applications, especially those involving corrosive or hazardous substances. Non-contact sensors, while more expensive, offer greater flexibility and can be used in a wider range of applications. They are particularly useful in industries where hygiene and safety are paramount, such as food and beverage, pharmaceuticals, and chemicals. The choice between contact and non-contact sensors depends on various factors, including the nature of the substance being measured, the environmental conditions, and the specific requirements of the application. As technology continues to advance, the capabilities and applications of both contact and non-contact level sensors are expected to expand, further driving their adoption in the global market.

Semiconductor Industries, Aerospace and Defense, Industrial Manufacturing, Oil & Gas, Other in the Industrial Level Sensor - Global Market:

Industrial level sensors play a vital role in various sectors, including semiconductor industries, aerospace and defense, industrial manufacturing, oil and gas, and others. In the semiconductor industry, level sensors are used to monitor and control the levels of chemicals and gases used in the manufacturing process. Precise level measurement is crucial to ensure the quality and consistency of semiconductor products. Level sensors help in maintaining the right balance of chemicals and gases, preventing wastage and ensuring efficient production processes. In the aerospace and defense sector, level sensors are used in various applications, including fuel level monitoring, hydraulic systems, and coolant systems. Accurate level measurement is essential for the safe and efficient operation of aircraft and defense equipment. Level sensors help in preventing overfilling or underfilling of tanks, ensuring optimal performance and safety. In industrial manufacturing, level sensors are used to monitor and control the levels of raw materials, intermediates, and finished products. They help in maintaining the right inventory levels, preventing production delays, and ensuring efficient use of resources. Level sensors are also used in process control applications, where precise measurement and control of levels are essential for maintaining product quality and consistency. In the oil and gas industry, level sensors are used to monitor and control the levels of crude oil, refined products, and other fluids. They help in preventing spills and leaks, ensuring safe and efficient operations. Level sensors are also used in custody transfer applications, where accurate measurement of levels is essential for billing and accounting purposes. In other industries, such as food and beverage, pharmaceuticals, and chemicals, level sensors are used to monitor and control the levels of liquids, powders, and granules. They help in maintaining the right balance of ingredients, ensuring product quality and consistency. Level sensors are also used in environmental applications, such as water and wastewater treatment, where accurate level measurement is essential for efficient operation and compliance with regulatory requirements.

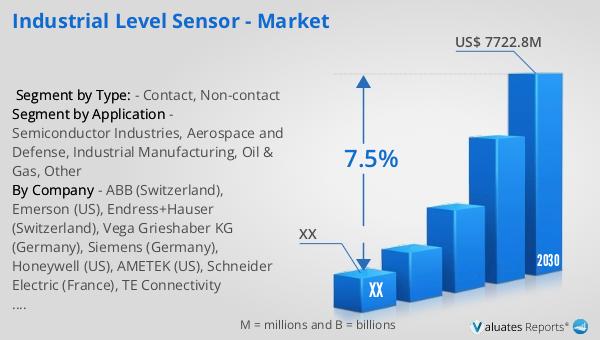

Industrial Level Sensor - Global Market Outlook:

The global market for industrial level sensors was valued at approximately US$ 4,683 million in 2023. It is projected to grow significantly, reaching an estimated size of US$ 7,722.8 million by 2030, with a compound annual growth rate (CAGR) of 7.5% during the forecast period from 2024 to 2030. This growth is driven by several factors, including the rising adoption of Industry 4.0 and the increasing use of level sensors in environmental applications. Industry 4.0, characterized by the integration of digital technologies into manufacturing processes, has led to increased demand for automation and precise measurement and control solutions. Level sensors play a crucial role in this transformation, providing accurate and reliable data for process optimization and efficiency. Additionally, the growing focus on environmental sustainability and the need for efficient resource management have led to increased adoption of level sensors in environmental applications, such as water and wastewater treatment. These trends present significant opportunities for growth in the industrial level sensor market, as industries continue to embrace new technologies and prioritize efficiency and sustainability.

| Report Metric | Details |

| Report Name | Industrial Level Sensor - Market |

| Forecasted market size in 2030 | US$ 7722.8 million |

| CAGR | 7.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ABB (Switzerland), Emerson (US), Endress+Hauser (Switzerland), Vega Grieshaber KG (Germany), Siemens (Germany), Honeywell (US), AMETEK (US), Schneider Electric (France), TE Connectivity (Switzerland), Gems Sensors (US) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |