What is Degassing System - Global Market?

Degassing systems are essential components in various industrial processes, designed to remove unwanted gases from liquids or other materials. These systems are crucial in ensuring the quality and efficiency of production processes across multiple sectors. The global market for degassing systems is driven by the increasing demand for high-quality products and the need to maintain optimal production conditions. Degassing systems are employed in industries such as oil and gas, manufacturing, packaging, and plastics, where the presence of gases can lead to defects, reduced efficiency, or compromised safety. The market is characterized by a variety of technologies and solutions tailored to specific applications, including membrane degassing systems, vacuum degassing systems, and flash degassing systems. As industries continue to evolve and demand higher standards of quality and efficiency, the role of degassing systems becomes increasingly important. The global market for these systems is expected to grow steadily, driven by technological advancements and the expanding applications of degassing technologies across different sectors. The market's growth is also supported by the increasing awareness of the benefits of degassing systems in improving product quality and process efficiency.

Membrane Degassing Systems, Vacuum Degassing Systems, Flash Degassing Systems, Other in the Degassing System - Global Market:

Membrane degassing systems are a popular choice in the global market due to their efficiency and versatility. These systems use semi-permeable membranes to separate gases from liquids, making them ideal for applications where precise control over gas removal is required. Membrane degassing systems are commonly used in water treatment, beverage production, and chemical processing, where the removal of dissolved gases is crucial for maintaining product quality and safety. Vacuum degassing systems, on the other hand, rely on creating a vacuum environment to remove gases from materials. This method is particularly effective in metallurgical processes, where the presence of gases can lead to defects in metal products. Vacuum degassing is also used in the production of high-purity materials, where even trace amounts of gases can compromise the final product. Flash degassing systems are another type of degassing technology, which involves rapidly reducing the pressure of a liquid to release dissolved gases. This method is often used in the oil and gas industry, where it is essential to remove gases from crude oil and natural gas to ensure safe and efficient processing. Flash degassing is also employed in the food and beverage industry, where it helps maintain the quality and shelf life of products. Other degassing systems in the market include chemical degassing, which uses chemical reactions to remove gases, and mechanical degassing, which employs physical agitation to release gases from liquids. Each of these systems has its own advantages and limitations, making them suitable for specific applications and industries. The choice of degassing system depends on factors such as the type of material being processed, the desired level of gas removal, and the specific requirements of the production process. As the global market for degassing systems continues to grow, manufacturers are investing in research and development to improve the efficiency and effectiveness of these technologies. This includes the development of new materials and designs for membranes, as well as advancements in vacuum and flash degassing techniques. The ongoing innovation in degassing systems is expected to drive further growth in the market, as industries seek to enhance their production processes and meet the increasing demand for high-quality products.

Oil & Gas, Manufacturing, Package, Plastics, Others in the Degassing System - Global Market:

Degassing systems play a vital role in various industries, including oil and gas, manufacturing, packaging, and plastics. In the oil and gas sector, degassing systems are used to remove gases from crude oil and natural gas, ensuring safe and efficient processing. The presence of gases in these materials can lead to safety hazards, reduced efficiency, and lower product quality. By employing degassing systems, companies in the oil and gas industry can improve the safety and efficiency of their operations, while also enhancing the quality of their products. In the manufacturing sector, degassing systems are used to remove gases from raw materials and finished products. This is particularly important in industries such as metallurgy, where the presence of gases can lead to defects in metal products. By using degassing systems, manufacturers can ensure the quality and integrity of their products, while also improving the efficiency of their production processes. In the packaging industry, degassing systems are used to remove gases from packaging materials, ensuring the quality and shelf life of packaged products. This is especially important in the food and beverage industry, where the presence of gases can lead to spoilage and reduced product quality. By employing degassing systems, companies in the packaging industry can enhance the quality and shelf life of their products, while also improving the efficiency of their production processes. In the plastics industry, degassing systems are used to remove gases from plastic materials, ensuring the quality and performance of plastic products. The presence of gases in plastic materials can lead to defects, reduced strength, and compromised performance. By using degassing systems, companies in the plastics industry can improve the quality and performance of their products, while also enhancing the efficiency of their production processes. Other industries that benefit from degassing systems include water treatment, chemical processing, and electronics manufacturing, where the removal of gases is crucial for maintaining product quality and safety. As the global market for degassing systems continues to grow, these technologies are expected to play an increasingly important role in enhancing the quality and efficiency of production processes across various industries.

Degassing System - Global Market Outlook:

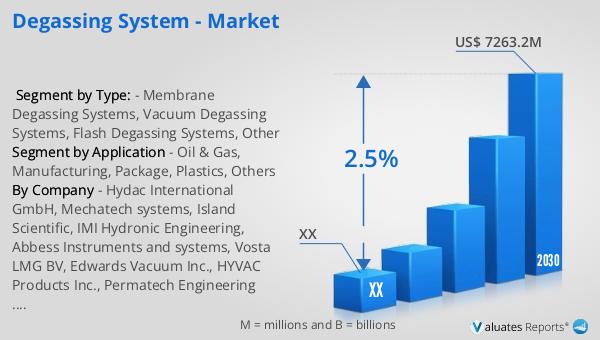

The global market for degassing systems was valued at approximately $6,132 million in 2023, with projections indicating a growth to around $7,263.2 million by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 2.5% during the forecast period from 2024 to 2030. The North American segment of the degassing system market was also valued at a significant amount in 2023, with expectations of reaching a higher value by 2030, although specific figures for this region were not provided. The steady growth in the global market can be attributed to the increasing demand for high-quality products and the need for efficient production processes across various industries. As industries continue to evolve and demand higher standards of quality and efficiency, the role of degassing systems becomes increasingly important. The market's growth is also supported by the increasing awareness of the benefits of degassing systems in improving product quality and process efficiency. The ongoing innovation in degassing systems is expected to drive further growth in the market, as industries seek to enhance their production processes and meet the increasing demand for high-quality products.

| Report Metric | Details |

| Report Name | Degassing System - Market |

| Forecasted market size in 2030 | US$ 7263.2 million |

| CAGR | 2.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hydac International GmbH, Mechatech systems, Island Scientific, IMI Hydronic Engineering, Abbess Instruments and systems, Vosta LMG BV, Edwards Vacuum Inc., HYVAC Products Inc., Permatech Engineering Services, Mass-VAC Inc |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |