What is Global Implants for Orthopedic Trauma Market?

The Global Implants for Orthopedic Trauma Market refers to the worldwide industry focused on the development, production, and distribution of medical devices used to treat orthopedic injuries. These injuries often result from accidents, falls, or sports-related activities and can include fractures, dislocations, and other bone-related traumas. Orthopedic implants are designed to support the healing process by stabilizing and aligning broken bones, facilitating proper bone growth, and restoring functionality. The market encompasses a wide range of products, including screws, plates, rods, and pins, which are made from materials like stainless steel, titanium, and bioabsorbable polymers. The demand for these implants is driven by factors such as the aging population, increasing incidence of osteoporosis and other bone-related conditions, advancements in medical technology, and rising awareness about the benefits of early intervention and treatment. As healthcare systems around the world continue to improve and access to medical care expands, the Global Implants for Orthopedic Trauma Market is expected to grow, providing critical solutions for patients in need of effective orthopedic care.

in the Global Implants for Orthopedic Trauma Market:

In the Global Implants for Orthopedic Trauma Market, various types of implants are utilized by different customers based on their specific needs and medical conditions. One of the most common types is the bone plate, which is used to stabilize fractures by holding the broken pieces of bone together. These plates come in various shapes and sizes to accommodate different bones and fracture types. Another widely used implant is the intramedullary rod, which is inserted into the marrow canal of a bone to provide internal support. This type of implant is particularly useful for fractures of long bones like the femur or tibia. Screws are also a fundamental component in orthopedic trauma care, used either independently or in conjunction with other implants to secure bones or plates in place. They vary in length, diameter, and thread type to suit different applications. Pins and wires, often made of stainless steel or titanium, are used for temporary fixation or to hold small bone fragments together. Additionally, bioabsorbable implants, made from materials that gradually dissolve in the body, are gaining popularity due to their ability to eliminate the need for a second surgery to remove the implant. These are particularly beneficial in pediatric cases where the bones are still growing. Custom implants, tailored to the specific anatomy of a patient, are also becoming more prevalent with advancements in 3D printing technology. These personalized solutions can offer better fit and function, leading to improved outcomes. The choice of implant type depends on various factors, including the location and severity of the fracture, the patient's age and overall health, and the surgeon's preference and expertise. As the market continues to evolve, new materials and designs are being developed to enhance the performance and safety of orthopedic implants, providing better options for patients and healthcare providers alike.

in the Global Implants for Orthopedic Trauma Market:

The applications of Global Implants for Orthopedic Trauma Market are diverse and cater to a wide range of medical needs. One of the primary applications is in the treatment of fractures, where implants such as plates, screws, and rods are used to stabilize and align broken bones. This is crucial for ensuring proper healing and restoring functionality to the affected limb. Another significant application is in joint replacement surgeries, where damaged or diseased joints are replaced with artificial implants. This is commonly seen in hip and knee replacements, which can significantly improve the quality of life for patients suffering from severe arthritis or joint damage. Spinal surgeries also utilize orthopedic implants to correct deformities, stabilize the spine, and relieve pressure on the spinal cord and nerves. These implants include rods, screws, and cages that provide structural support and promote spinal fusion. Additionally, orthopedic implants are used in the treatment of sports injuries, such as ligament tears and tendon ruptures. In these cases, implants like screws and anchors are used to reattach the torn tissues to the bone, facilitating proper healing and enabling athletes to return to their activities. Pediatric orthopedics is another important application area, where implants are used to treat congenital deformities, growth plate injuries, and fractures in children. The use of bioabsorbable implants is particularly beneficial in this population, as they eliminate the need for a second surgery to remove the implant. Furthermore, orthopedic implants are used in trauma cases resulting from accidents or falls, where immediate surgical intervention is required to stabilize the bones and prevent further complications. The versatility and effectiveness of orthopedic implants make them an essential component of modern medical care, providing solutions for a wide range of conditions and improving patient outcomes.

Global Implants for Orthopedic Trauma Market Outlook:

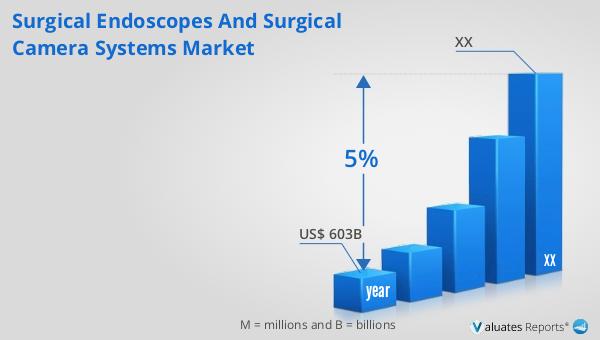

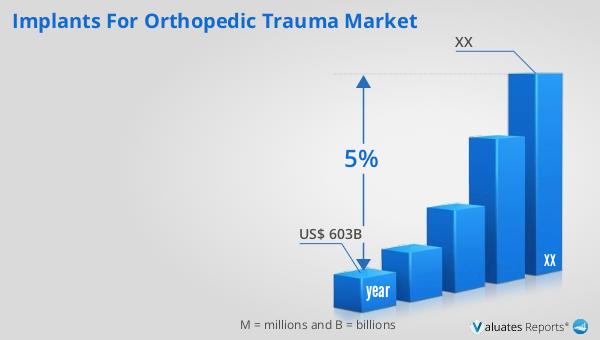

Based on our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, increasing prevalence of chronic diseases, and rising demand for minimally invasive procedures. The aging population is also a significant contributor, as older individuals are more likely to require medical devices for various health conditions. Additionally, expanding healthcare infrastructure in emerging markets and increasing healthcare expenditure are expected to further fuel the market growth. The medical device industry encompasses a wide range of products, including diagnostic equipment, surgical instruments, and therapeutic devices, all of which play a crucial role in improving patient care and outcomes. As the market continues to evolve, innovations in areas such as digital health, wearable devices, and personalized medicine are likely to create new opportunities for growth and development. The increasing focus on patient-centric care and the integration of advanced technologies into medical devices are expected to drive the market forward, providing better solutions for patients and healthcare providers alike.

| Report Metric | Details |

| Report Name | Implants for Orthopedic Trauma Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |