What is Global Heavy-Payload Robot Arm Market?

The Global Heavy-Payload Robot Arm Market refers to the worldwide industry focused on the production, distribution, and utilization of robotic arms capable of handling heavy loads. These robotic arms are designed to perform tasks that require significant strength and precision, making them essential in various industrial applications. Heavy-payload robot arms are commonly used in sectors such as automotive manufacturing, aerospace, construction, and logistics, where they help in tasks like welding, material handling, assembly, and packaging. The market for these robotic arms is driven by the increasing demand for automation, the need for improved efficiency and productivity, and the growing emphasis on worker safety. As industries continue to adopt advanced technologies, the demand for heavy-payload robot arms is expected to rise, leading to innovations and advancements in this field.

in the Global Heavy-Payload Robot Arm Market:

The Global Heavy-Payload Robot Arm Market encompasses a variety of types that cater to the diverse needs of different customers. One of the primary types is the articulated robot arm, which is highly flexible and can move in multiple directions, making it suitable for complex tasks such as welding, painting, and assembly. These arms are commonly used in the automotive and aerospace industries due to their precision and versatility. Another type is the SCARA (Selective Compliance Assembly Robot Arm) robot, which is known for its speed and accuracy in tasks like pick-and-place, assembly, and packaging. SCARA robots are widely used in electronics manufacturing and other industries where high-speed operations are crucial. Cartesian or gantry robots are another type, characterized by their linear movement along the X, Y, and Z axes. These robots are ideal for tasks that require high precision and repeatability, such as CNC machining, 3D printing, and material handling. Delta robots, with their spider-like structure, are designed for high-speed and high-precision applications, particularly in the food and beverage, pharmaceuticals, and electronics industries. They excel in tasks like sorting, packaging, and assembly. Collaborative robots, or cobots, are designed to work alongside human workers, enhancing productivity and safety. These robots are equipped with advanced sensors and safety features, making them suitable for tasks that require human-robot interaction, such as assembly, quality inspection, and material handling. Heavy-payload robot arms also include specialized types like palletizing robots, which are used for stacking and organizing products on pallets, and painting robots, which are designed for precise and consistent application of paint in automotive and other manufacturing processes. Each type of heavy-payload robot arm offers unique advantages and is chosen based on the specific requirements of the application and industry. The choice of robot arm type depends on factors such as load capacity, reach, speed, precision, and the nature of the task to be performed. As industries continue to evolve and adopt automation, the demand for various types of heavy-payload robot arms is expected to grow, driving further advancements and innovations in this market.

in the Global Heavy-Payload Robot Arm Market:

The Global Heavy-Payload Robot Arm Market finds applications across a wide range of industries, each leveraging the capabilities of these robotic arms to enhance efficiency, productivity, and safety. In the automotive industry, heavy-payload robot arms are extensively used for tasks such as welding, painting, assembly, and material handling. These robots help in achieving high precision and consistency, reducing production time and costs. In the aerospace industry, heavy-payload robot arms are employed for assembling aircraft components, drilling, and riveting. The precision and reliability of these robots ensure the quality and safety of aerospace products. The construction industry also benefits from heavy-payload robot arms, particularly in tasks like bricklaying, concrete pouring, and material handling. These robots can handle heavy materials with ease, improving the speed and accuracy of construction projects. In the logistics and warehousing sector, heavy-payload robot arms are used for palletizing, depalletizing, and sorting packages. They enhance the efficiency of warehouse operations, reducing the need for manual labor and minimizing errors. The electronics industry utilizes heavy-payload robot arms for tasks such as PCB assembly, soldering, and testing. The precision and speed of these robots are crucial in maintaining the quality and reliability of electronic products. In the food and beverage industry, heavy-payload robot arms are used for packaging, sorting, and palletizing. These robots ensure the hygiene and safety of food products while increasing the efficiency of production lines. The pharmaceutical industry also relies on heavy-payload robot arms for tasks like packaging, labeling, and handling hazardous materials. The accuracy and reliability of these robots are essential in maintaining the quality and safety of pharmaceutical products. Heavy-payload robot arms are also used in the metal and machinery industry for tasks such as welding, cutting, and material handling. These robots can handle heavy and bulky materials with precision, improving the efficiency and safety of manufacturing processes. The oil and gas industry employs heavy-payload robot arms for tasks like drilling, inspection, and maintenance. These robots can operate in hazardous environments, reducing the risk to human workers. Overall, the applications of heavy-payload robot arms are diverse and continue to expand as industries seek to improve their operations through automation.

Global Heavy-Payload Robot Arm Market Outlook:

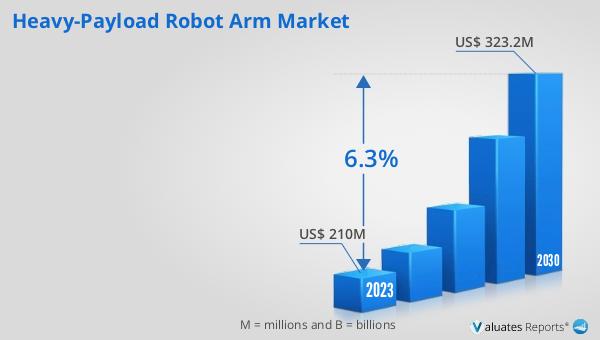

The global Heavy-Payload Robot Arm market was valued at US$ 210 million in 2023 and is anticipated to reach US$ 323.2 million by 2030, witnessing a CAGR of 6.3% during the forecast period 2024-2030. This market growth reflects the increasing adoption of automation across various industries, driven by the need for enhanced efficiency, productivity, and safety. Heavy-payload robot arms are becoming essential tools in sectors such as automotive, aerospace, construction, logistics, and manufacturing, where they perform tasks that require significant strength and precision. The rising demand for these robotic arms is also fueled by advancements in technology, which have led to the development of more sophisticated and versatile robots. As industries continue to evolve and embrace automation, the heavy-payload robot arm market is expected to experience sustained growth, offering numerous opportunities for innovation and development. The projected market value and growth rate underscore the importance of heavy-payload robot arms in modern industrial applications and highlight the potential for further advancements in this field.

| Report Metric | Details |

| Report Name | Heavy-Payload Robot Arm Market |

| Accounted market size in 2023 | US$ 210 million |

| Forecasted market size in 2030 | US$ 323.2 million |

| CAGR | 6.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |