What is Global Weld Checkers Market?

The Global Weld Checkers Market refers to the worldwide industry focused on the production, distribution, and utilization of devices known as weld checkers. These devices are essential in ensuring the quality and integrity of welds in various industrial applications. Weld checkers are used to detect flaws, inconsistencies, and defects in welded joints, which are critical for maintaining the safety and performance of structures and machinery. The market encompasses a wide range of products, including portable handheld devices, automated systems, and advanced technologies that use ultrasonic, radiographic, and other non-destructive testing methods. The demand for weld checkers is driven by the need for stringent quality control in industries such as construction, automotive, aerospace, and energy. As these industries continue to grow and evolve, the importance of reliable weld inspection tools becomes increasingly significant. The global market for weld checkers is characterized by technological advancements, increasing regulatory standards, and a growing emphasis on safety and efficiency in manufacturing processes.

AC Power Supply, DC Inverter, AC Inverter, Transistor, Energy Storage in the Global Weld Checkers Market:

In the context of the Global Weld Checkers Market, various power supply and energy storage technologies play a crucial role in the functionality and efficiency of weld checkers. AC Power Supply refers to the alternating current power sources that provide the necessary electrical energy for operating weld checkers. These power supplies are essential for ensuring that the devices can function reliably in different industrial environments. DC Inverter technology, on the other hand, involves converting direct current into alternating current, which is particularly useful in portable weld checkers that need to operate in remote locations without access to a stable AC power source. AC Inverters are similar but work in the opposite direction, converting AC to DC, which can be beneficial for specific types of weld checkers that require direct current for optimal performance. Transistors are semiconductor devices used to amplify or switch electronic signals in weld checkers, playing a vital role in the precision and accuracy of these devices. Energy Storage systems, such as batteries and capacitors, are critical for ensuring that weld checkers can operate continuously without interruption, especially in situations where a stable power supply is not available. These technologies collectively enhance the reliability, portability, and efficiency of weld checkers, making them indispensable tools in various industrial applications.

Electricity, Petrochemicals, Aerospace, Transportation, Others in the Global Weld Checkers Market:

The usage of Global Weld Checkers Market spans across several critical industries, including Electricity, Petrochemicals, Aerospace, Transportation, and others. In the Electricity sector, weld checkers are used to inspect and ensure the integrity of welded joints in power plants, transmission lines, and electrical substations. This is crucial for preventing failures and ensuring the continuous supply of electricity. In the Petrochemicals industry, weld checkers play a vital role in maintaining the safety and reliability of pipelines, storage tanks, and processing equipment. The ability to detect and address welding defects early helps prevent leaks, explosions, and environmental contamination. In the Aerospace industry, weld checkers are used to inspect the welds in aircraft structures, engines, and components. Given the high safety standards and the critical nature of aerospace applications, ensuring the quality of welds is paramount. In the Transportation sector, weld checkers are employed to inspect the welds in vehicles, railways, and ships. This helps in maintaining the structural integrity and safety of transportation systems. Other industries that benefit from weld checkers include construction, manufacturing, and oil and gas, where the quality and reliability of welded joints are essential for operational efficiency and safety.

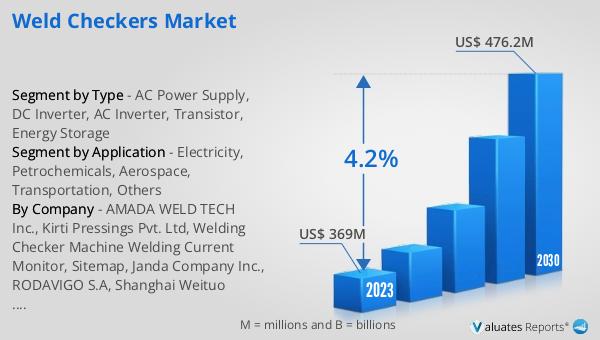

Global Weld Checkers Market Outlook:

The global Weld Checkers market was valued at US$ 369 million in 2023 and is anticipated to reach US$ 476.2 million by 2030, witnessing a CAGR of 4.2% during the forecast period 2024-2030. This growth reflects the increasing demand for reliable and efficient weld inspection tools across various industries. The market's expansion is driven by factors such as technological advancements, stringent regulatory standards, and the growing emphasis on safety and efficiency in manufacturing processes. As industries continue to evolve and prioritize quality control, the importance of weld checkers in ensuring the integrity and performance of welded joints becomes more pronounced. The market outlook indicates a positive trend, with significant opportunities for innovation and development in the field of weld inspection technology.

| Report Metric | Details |

| Report Name | Weld Checkers Market |

| Accounted market size in 2023 | US$ 369 million |

| Forecasted market size in 2030 | US$ 476.2 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AMADA WELD TECH Inc., Kirti Pressings Pvt. Ltd, Welding Checker Machine Welding Current Monitor, Sitemap, Janda Company Inc., RODAVIGO S.A, Shanghai Weituo Optoelectronic Equipment Co., Ltd., DKSH, Wuxi Haifei Welding Equipment Co., Ltd., Shanghai Hongfu Instrument Co., Ltd., Wuhan Hairun Quanxing Technology Co., Ltd., Zhongtou Electronics, Shanghai Qishao Mechanical and Electrical Technology Co., Ltd., Genyi Industrial Co., Ltd., Spot Weld, Inc., CHOWEL CORPORATION |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |